Battery Anode Materials Vibrating Sieve

![[field:title/]](/uploads/220621/1-22062116053I13.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Screening accuracy 1-70%

Yield can be increased by 0.5-10 times

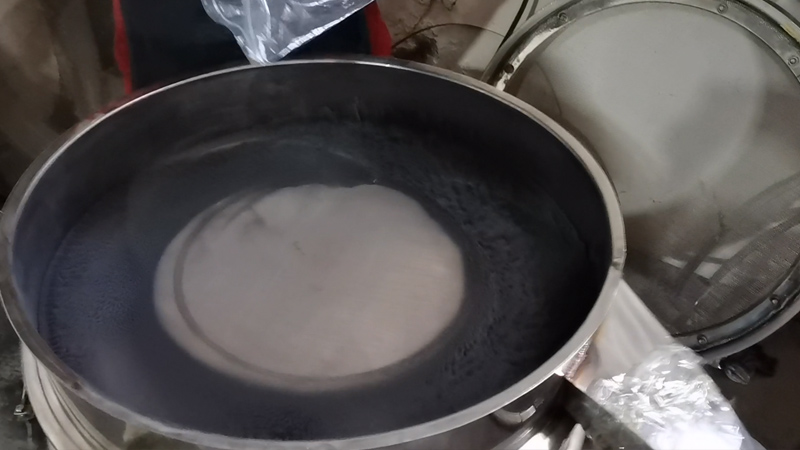

Introduction of Battery Anode Materials Vibrating Sieve

Battery materials anode vibrating sieve needs to be made of 304 stainless steel for the whole machine. The design should be closed and the inlet and outlet should be designed to be connected to automatic feeding and receiving devices. This series of equipment has the characteristics of small size, low energy consumption, convenient movement, good sealing performance and high safety performance.

Battery materials anodevibrating sieve, also called lithium battery material vibrating sieve, is mainly used to separate out the materials that do not meet the production requirements for re-crushing. However, in the screening process, due to the relatively fine cathode materials and the friction between the materials, problems such as agglomeration and adsorption caused by static electricity will occur, which will greatly reduce the screening accuracy and output, and iron and copper metals will pollute the raw materials, resulting in a reduction in the capacity of lithium batteries. , so at this time, it is necessary to use battery anode materials vibrating sieve with ultrasonic wave system to make the sieve vibrate at high frequency, which can screen battery powder on meshes as fine as 20 microns without blinding or blocking.

Benefits of Battery Anode Materials Vibrating Sieve

1. Compared with the rotary vibrating screen, the ultrasonic vibrating screen has higher screening accuracy. For example, when sieving 200 mesh graphite, the rotary vibrating screen may feed 100kg of material and sieve the yield in one hour, and the yield is only 20kg, and other fine powders are on the upper frame. Difficult to sift through. However, after using the ultrasonic vibrating screen to feed 100kg and sieving for one hour, the yield may reach 50kg per hour. The sieving accuracy and the yield of fine powder can be greatly improved.

2. The feeding amount of the ultrasonic vibrating screen of the same size can be greatly improved, mainly because the screening accuracy of the ultrasonic vibrating screen is high, and it can handle a larger output.

Technical Parameters of Battery Anode Materials Vibrating Sieve

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibrating screen easily solves the problem of lithium battery cathode material spillage

Vibrating screen is an effective solution to the screening problems of materials: strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity and other screening problems, with excellent performance! The screening accuracy can be increased by 1-70% compared with the ordinary vibrating screen, and the output can be increased by 0.5-10 times. Dry powder particle size can be classified to 25μm (600 mesh). The positive electrode material of lithium battery is generally a battery that uses lithium alloy metal oxide as the positive electrode material, graphite as the negative electrode material, and uses a non-aqueous electrolyte.

The production of lithium battery cathode raw materials needs to use vibrating screening equipment for grading work, and use vibrating screening equipment to separate out the raw materials that do not meet the production requirements for re-crushing and reuse. In the screening process, due to the fineness of the raw materials of lithium batteries, and the problem of blocking nets caused by static electricity caused by static electricity, it is difficult for ordinary vibrating screens to carry out effective screening work. The vibrating screen designed and produced by Dahan Vibration Machinery can effectively solve the problem of blockage of raw materials for lithium batteries.

The lithium battery vibrating screen is based on the ordinary vibrating screen with a net cleaning device added to solve the problem of blocking the net, and an intelligent vibration source is selected. Ultrasonic vibration wave, so that the material is suspended on the screen surface at a low altitude, which effectively solves the problem of blockage of lithium battery materials and improves the screening accuracy. This series of vibrating screens has high screening accuracy, small size, can effectively solve the problem of blocking the screen, low noise, low energy consumption, and the fully enclosed design of the whole machine can effectively prevent the escape of lithium battery powder and meet environmental protection standards. It is the equipment of today's lithium battery and high-precision industries.

-

Non-stick properties or anti-stick properties, easy to clean

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.