Corrosion Resistant Vibro Sifter

![[field:title/]](/uploads/211126/1-2111261500555a.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Because it is made of polypropylene, this material is non-toxic

It can sieve powder and granules, and can also filter liquid

The bouncing ball cleaning device can continuously hit the screen through frequency vibration

Introduction of corrosion resistant vibro sifter

Corrosion resistant vibro sifter is made of PP plastic material in contact with the material, and the bottom barrel and the beam ring have also been sprayed. The special processing technology is used to meet the acidity, alkalinity and corrosiveness of the produced material. The screening operation of materials is specifically aimed at solving the problems that some special materials are prone to oxidation and corrosion after they come into contact with Q235 ordinary carbon steel and SUS304 stainless steel.

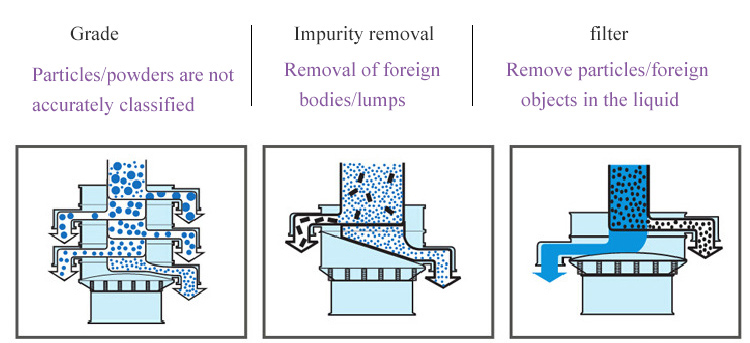

Function of corrosion resistant vibro sifter

Sieving chemical powder

1. Classification: The corrosion resistant vibro sifter can be used to continuously and accurately divide the product into multiple layers and use it once to separate and screen out six groups of products with different particle sizes without inconsistent particle size ratio.

2. Liquid removal: This equipment can be used in single layer and multiple layers, which can effectively process solid and liquid mixtures, quickly realize solid-liquid separation, and filter out different target materials.

3. Removal of impurities: This equipment can quickly separate a large amount of materials and remove small parts of materials of different sizes.

Benefits of corrosion resistant vibro sifter

1. The screen machine is made of polypropylene propylene pp material, which has good anti-corrosion properties. It can screen acid, alkali and strong alkaline materials, effectively solve the oxidation, so that the materials will not deteriorate during the screening process, and the screening effect of the materials will not be affected.

2. Because it is made of polypropylene, this material is non-toxic, colorless, and tasteless, and will not cause any harm to human body functions when used.

3. Long service life: Polypropylene material is relatively durable and will not be severely worn with the vibration of the vibrating machine. At the same time, because the plastic vibrating screen is resistant to corrosion, high temperature, strong alkali corrosion, rigidity and tensile strength, and can be added The oxygen agent prevents the vibrating screen from aging and has a longer service life than ordinary vibrating screens.

4. It can sieve powder and granules, and can also filter liquid. The filtration capacity can be as high as 20 cubic meters/hour, and the sieve weight can reach 100-2000 kg/hour.

5. The bouncing ball cleaning device can continuously hit the screen through frequency vibration, so that the material can pass through the screen smoothly without blocking the screen, and the screening efficiency is high.

Working principle of corrosion resistant vibro sifter

Corrosion resistant vibro sifter uses YZUL vertical vibration motor as the excitation source. The eccentric weight at the upper and lower ends of the vibration motor converts the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, which is transmitted to the screen surface, and the material passes through the feed After entering the equipment, according to the screening requirements of the material, the material passes through the 1-5 layers of screens with different meshes. In this process, the cleaning device (bouncing ball) located under the screens of each layer will be Constantly hitting the screen allows the material on the screen to pass through the screen smoothly, and effectively solves the problem of material blockage. The materials of different meshes are discharged on each layer after passing through the screens of the corresponding meshes of each layer. It is discharged from the mouth, and finally achieves the purpose of screening and removing impurities or filtering and grading.

Technical parameters of corrosion resistant vibro sifter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of corrosion resistant vibro sifter

Corrosion resistant vibro sifter is suitable for many industries, such as food industry, pharmaceutical industry, chemical industry, etc. It can solve the problem of screening strong acid and strong alkaline materials.

Food industry: flour, milk powder, condiments, starch, fish meal, rice flour, dextrin, beverages, fruit juice, sugar, soy sauce, pineapple juice, yeast liquid, etc.

Chemical industry: fluorescent powder, paint, PVC resin powder, citric acid, resin powder, polyethylene powder, washing powder, etc.

Pharmaceutical industry: pharmaceutical intermediates, medical auxiliary materials, traditional Chinese medicine powder, traditional Chinese medicine liquid, western medicine powder, western medicine liquid, etc.

Ceramic abrasive metallurgy industry: aluminum silver paste, mud, kaolin, quartz sand, alumina, artificial black aluminum, graphite, silicon carbide, sprayed soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.

-

Plastic Powder Vibratory Sifter

Gentle screening will not damage any PVC resin structure, and it is not easy to generate static electricity. ...

-

Vibratory Sifter for Plastic Pellets

The specifications can be configured arbitrarily, and the finest sieving is up to 500 meshes (28μm). ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.