Vibrating Sieve

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Sieving to 500 meshes, filtering up to 5 microns

Net cleaning device can be added to reduce material clogging

Select 1~5 particle size separation tasks according to the screening purpose

What is a vibrating sieve?

Vibrating sieve uses a custom-made layered sieve and 3D motion to screen products, it can be used to screen dry powder or granular products as well as wet products and liquids, it can eliminate foreign matter in products Through continuous filtration, multiple operations can be performed in just 1 operation Up to 5 product separation.

Vibrating sieve can sieve up to 500 mesh, with various sizes (from 400mm to 2000mm) to meet the screening needs of different industries, with an output of 100 to 3300kg/h, widely used in food and beverage, pharmaceutical, paper and pulp, metal powder , powder coatings and other industries, and can be fully customized according to your application.

What is the working principle of vibrating sieve?

Vibrating sieve uses the YZUL vertical vibration motor as the excitation source, and uses the eccentric weights at the upper and lower ends of the vibration motor to convert the rotary motion into a horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; The feed inlet enters the equipment. According to different material screening requirements, the material passes through 1-5 layers of sieving with different mesh metal woven screens. In this process, a cleaning device is located under the screens of each layer. (Bouncing ball) Continuously hitting the screen through frequency vibration, so that the materials on the screen can be smoothly screened through the screen, and effectively solve the problem of material blockage. After the materials of different meshes pass through the screens of the corresponding meshes of each layer It is discharged at the discharge port of each layer, and finally achieves the purpos e of screening and removing impurities or filtering and grading.

What are the product advantages of vibrating sieve?

1. The mesh size is as fine as 500 mesh (28 microns), and the filtration is as fine as 5 microns, which can realize sieving and filtration.

2. All the feeding materials are automatically unloaded, and there is no material stored in the machine. The screen surface and the screen surface have a larger capacity than other types of screen surface machines, and the processing capacity per hour can reach 100-3300kg.

3. The three-dimensional vibration motor is designed with automatic cleaning and anti-blocking devices (optional bouncers, drum brushes, and ultrasonic cleaning devices) to reduce the chance of blocking the screen.

4. Optionally install 1-5 layers of screen mesh, which can sort or filter 2-6 kinds of products of different specifications at the same time.

5. Various screen structures can be used according to different needs, and the time for replacing a screen is shortened to 3-5 minutes.

-

Sieving silica powder

-

Filter soymilk

What types of vibrating sieve are there?

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What are the components of the vibrating sieve?

Rotary vibrating screen is composed of dust cover, screen frame, screen, net frame, net cleaning device, motor (vibration source), damping spring, base and other parts.

Dust cover: It is composed of a feed inlet and an oblique cone, and its lower end is connected with the screen frame to prevent the dust in the workshop from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel and plastic. Etc. 3 kinds of materials.

Screen frame: It is made of steel plate coiled and welded, with bearing rings at the upper and lower ends, and flange rings in the lower part, which are used to fix the structure of the screen components.

Vibration motor: vertical vibration motor, divided into four specifications of 2, 4, 6, 8, and horizontal, the number of vibrations are 2870, 1460, 980, 740RPM, and can be designed as explosion-proof type (flammable and explosive occasions)

Screen: Models are φ600, 800, 1000, 1200, 1500, 1800, etc., and the materials are stainless steel, carbon steel, and plastic.

Screen cleaning device: clean the blocked materials in the screen mesh to increase the output. It is made of silicone and rubber. You can also choose an ultrasonic cleaning device (635 mesh fine powder with static electricity).

Damping spring: There are 12-20 vibration isolation springs along the vibration transmission body. The base is welded by steel coils. There are access doors and electrical switch seats on the bottom wall. An annular flange is welded on the upper part of the base wall, and the flange is connected with the vibration transmission body through a vibration isolation spring.

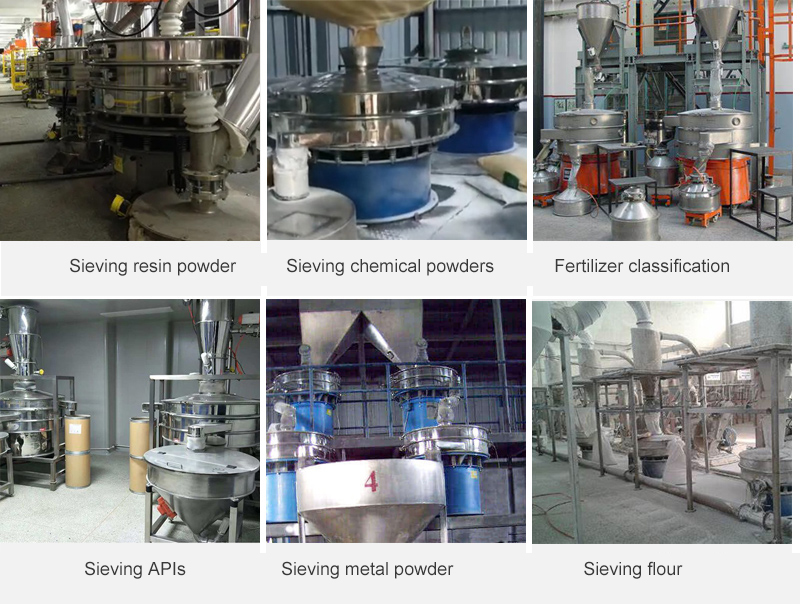

Vibrating screen use site

The main uses of vibrating sieve are as follows:

1. Removal of impurities: high-fluidity powder processing can quickly remove large particles or fine powder with little content.

2. Grading and screening: Continuously select mixed materials of different particle sizes and classify them into different particle size grades. It can be divided into one layer, two layers, three layers, four layers and so on. What's more, up to 5 stages of product separation can be continuously filtered in just 1 operation.

3. Solid-liquid separation: Quickly remove insoluble solids in various slurries, and remove unqualified impurities or suspended solids in slurries.

typical application:

Chemical industry: resin, paint, industrial medicine, cosmetics, paint, Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Metals, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy carbonic acid Calcium , quartz sand, etc.

Pollution treatment: waste oil, wastewater, dyeing and finishing wastewater, additives, activated carbon, etc.

What are the criteria for choosing a vibrating screening machine?

1. Production demand

In the case of the same material, the larger the size of the rotary vibrating screen, the larger the screening output. According to the output in the above table, you can refer to choose the type of rotary vibrating screen that suits you;

2. Material situation - type, particle size and classification

The type of material determines the material of the vibrating screen:

Choose 304/316 stainless steel vibrating screen for food, medicine and other high hygienic standards or corrosive materials;

3. It is easy to react with metal and is corrosive, choose plastic material vibrating screen;

Titanium alloy vibrating screen is selected for materials that need to screen nitric acid, sulfuric acid, chloride and other strong acid, strong alkali and strong corrosive materials;

For general materials without special hygiene requirements or corrosive properties, carbon steel vibrating screens can be selected.

4. The particle size distribution of the material determines the selection of the mesh number:

The mesh number of the three-dimensional vibrating screen can be from 2 mesh to 500 mesh. According to the particle size required to be screened, select screens with different mesh numbers to screen out the materials that meet the requirements.

5. Material grading requirements determine the number of screen layers:

The number of layers of the screening machine is 1-5 layers. The mesh number of each layer is different. The screen below the screen has the smallest aperture. According to the actual needs of the material to be screened, choose how many layers of screens and how many meshes to use.

-

Stainless Steel Vibrating Sieve

The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high.

-

Removal of oversized material and foreign particle contamination from chocolate....

-

3D Printing Powders Vibrating Sieve

Maintain the size of the mesh port and stabilize the screening accuracy....

-

Quick-frozen Corn Vibrating Sieve

The large aperture screen ensures that the corn is not stuck and improves ....

-

Types and applications of vibrating sieve plates

The sieve plate of the vibrating sieve is one of the important structures in the sieveing equipment such... ...

-

Application of flour vibrating sieve in flour processing

The loss of the screen of the metal powder sieving machine is very troublesome, so do you ...

-

Application of flour vibrating sieve in flour processing

Flour vibrating sieve is mainly used to sieve out large particles of impurities, clumps an.. ..

-

Features and applications of small stainless steel vibrating sieve

Small stainless steel vibrating sieve generally refers to 400, 600 type 304/316 stainless steel vibrating sieve. ...

-

Application of flour vibrating sieve in flour processing

Flour vibrating sieve is mainly used to sieve out large particles of impurities, clumps and pollutants in flour ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.