Grain Vibro Separator

![[field:title/]](/uploads/211129/1-2111291001111D.jpg)

Callback

| Mesh size: | 2-500 mesh (0.35mm-0.028mm) |

| Capacity: | 100-3300kg/h |

| Layers: | 1-5 layers |

The removal rate is 90%. The removal rate of inorganic impurities was 92%.

Rubber balls under the sieve to reduce sieve clogging

Adjust the time the product stays on the sieve with the adjustable sieve surface angle

Application: wheat, rice, corn, soybean, cotton seeds, etc.

Introduction of grain vibro separator

Whether it is processing corn or wheat, the freshly recovered raw grains must be screened and cleaned before further processing. The grain vibro separator is suitable for impurity removal, grading and screening of wheat, soybeans, corn, peanuts, rapeseed, rice and other grains Working, the dust, weeds, stalks and other sundries of wheat seeds can be removed by using different layers of screens. The first layer sieves out the weeds, stalks and other sundries in the sieved grain, and the qualified wheat enters the second layer through the sieve, and is discharged through the second layer outlet, while the dust smaller than the mesh size of the second layer sieve Other impurities fall into the third layer and are discharged to complete the whole process.

Grain vibro separator can excellently complete the grain industry such as grain depots and flour mills. It can completely replace labor, and the output is very large, so that you no longer have to worry about the problem of grain sieving.

Application of grain vibro separator

Using the above main functions and supplemented by other functions, according to the nature of materials and processing requirements:

(1) Removal of impurities: Screening according to the strength and shape of materials can easily remove impurities such as stones and dust in grains, such as corn, wheat, soybeans, rice and other grain processing jobs are widely used.

(2) Classification: Classify according to the specific gravity of the material, and accurately separate particles of different sizes from the product, so that the final material can be classified into different sizes.

Screening and grading equipment are vibrating equipment according to their working principles, and the screening equipment is widely used in large quantities, so the grain vibro separator is generally used in the grain processing industry. The following shows you the application in different grain industries:

Featured videos

-

Grain vibro separator for sieving sesame

-

Grain vibro separator for sieving corn seeds

Benefits of grain vibro separator

1. Remove coarse-grained impurities, such as large grains, thin ropes, and straw. Its vibration action helps to remove and destroy mounds and mud balls.

2. The sieve has at least two layers. The first layer can separate coarse debris larger than grains (such as large pieces of wood, twine and straw), and the second layer can separate fine debris smaller than grains (such as sand and broken grains). ), it can also classify various materials according to different sizes.

3. Quick and easy to replace the sieve, there are rubber balls under the sieve to reduce the clogging of the sieve.

4. The closed system eliminates the problem of dust in the air, and manual interaction is pollution-free.

5. It can be equipped with casters as needed, which is convenient for moving in the workshop.

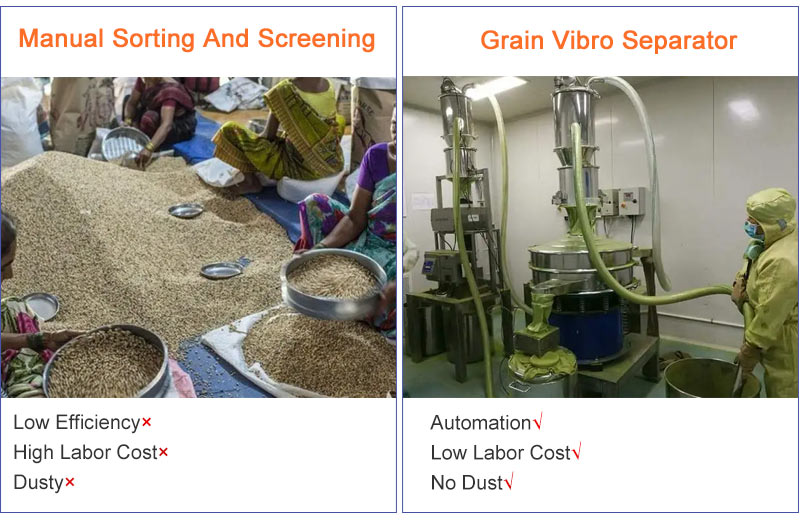

Grain vibro separator VS manual sorting and screening

Grain vibro separator is a method of sorting materials by using one or several layers of static or moving sieves according to the different particle sizes of materials. Compared with manual screening, the advantage of using grain vibro separator for screening is fast and uniform , The screening effect is good, and it can save a lot of time. The traditional manual sorting efficiency is relatively low, and the error is relatively large. From the perspective of long-term development, manual sorting requires a large number of workers, with low efficiency, large errors, and rising labor costs year by year.

Technical parameters of grain vibro separator

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases

| Material | Proportion | Mesh size | Method Wet | Capacity ((kg/hr IT/hr)) |

| wheat starch | 1 | 250mesh | Dry | 3200 IT |

| flour | 0.6 | 24mesh | wet | 1500㎏ |

| soy sauce | 1 | 100mesh | Dry | 6500 IT |

| salt | 1.2 | 30/80mesh | 5000㎏ | |

| corn starch | 0.6 | 40mesh | 1600㎏ | |

| Millet | 0.15 | 250 mesh | 600kg | |

| sunflower seeds | 0.04 | 80 mesh | 3000kg |

Related Case Studies

-

Sorting Wheat

It is mainly used for the classification of wheat and the removal of impurities. It can be used to screen and classify wheat starch, flour, rice flour, corn starch, potato starch, etc. It can achieve a good screening purpose by controlling the opening and closing of the gate, and it can be fed for a long time. point.

-

Rice Seed Sorting

It mainly removes impurities and grades the rice seeds, which can remove the platycodon, dust, weeds, etc. in the rice seeds, and can also classify the rice seeds. The specific rice seed screening machine can be divided into several grades, which can be determined according to the specific needs of customers.

-

Corn Sorting

It is mainly used for size classification of corn kernels. The product enters the feeding port of the vibro separator evenly from the feeder. Several kinds of products and unqualified objects on and under the sieve are screened out, and discharged from their respective outlets and flow into the silo or bin.

-

Clean and hygienically filter, remove impurities and grade food ...

-

Potato Starch Vibrating Screen

The discharging port can be adjusted 360 degrees arbitrarily ...

-

Sieve out the sand in the sesame or the carbon residue in the fried sesame ...

-

Remove the soil and impurities in the cocoa, and remove the coarse particles ...

-

Grain vibro separator to choose vibro sifter

The reason for choosing the linear vibrating screen for Grain vibro separator? Grain vibro separator ...

-

Quick-frozen Corn Vibrating Sieve Screening Process

The utility model relates to a snow-removing and impurity-removing vibrating screen for the feeding ...

-

How much is a wheat flour sifter

Flour is a food material and generally requires high sanitary conditions. Therefore, Dahan recommend...

-

Sesame sieve price

The principle of screening is mainly to use the difference in particle size between sesame and impu...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.