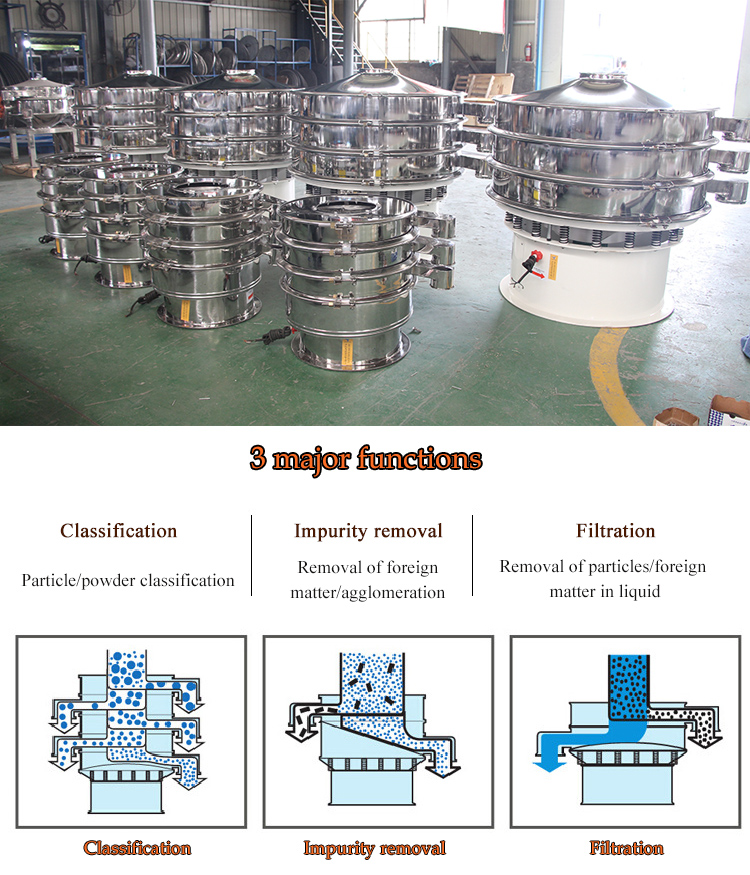

Vibratory Sifter

Callback

| Diameter: 400mm-2000mm | Mesh: 2-500 mesh |

| Capacity: 100-3300kg/h | Power: 0.25-3KW |

Classification: The mixture of different particle sizes is continuously sorted and selected to become the specification products of different particle size grades.

Removal of impurities: Quickly remove large particles or fine powders with very little content.

What is vibratory sifter?

Vibratory sifter is a rotary vibratory screening system ideal for screening feed ingredients and final production inspection of finished powders for the separation process of solids in liquids, for the separation of different particle sizes in the same product, for the safety of eliminating foreign bodies Sieving, for the homogenization of granules, etc.

It allows a throughput of 100 to 25,000 kg/h, depending on the product, mesh size and the feed flow of the machine. It is suitable for sieving from 36 microns to 25 mm, and the size allows up to 5 sieves to separate up to 6 products.

Working and Principle of Vibratory Sifter

Vibratory sifter is based on the principle of "rotational motion", the mixture is placed in the center of the screen, and then moves to the periphery along a spiral path, while the fine particles pass through it, so that the powdery material is separated, and the impurities are cleaned up and then the next round of material The process of separation movement.

Benefits of our vibratory sifter

1. Wide application: sieving fine to 500 mesh or 0.028mm powder and granular, liquid materials can be filtered to 5 microns.

2. It is not easy to block the net: Bouncing ball/ultrasonic/rotating drum cleaning device can be selected to prevent the mesh from clogging.

3. Multi-layer screening: 1-5 layers of multi-layer screening can obtain 2-6 different specifications of finished products.

4. No pollution: Fully sealed structure, no powder overflow, no liquid overflow.

5. Automation: Impurities and coarse materials are automatically discharged, and continuous operation is possible.

6. Convenient operation: The discharge port can be rotated 360°, and it only takes 3-5 minutes to replace the screen.

Technical parameters

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

For Vibratory Sifter solutions

| Material | Proportion | Mesh | Processing method | Capacity (kg/hr IT/hr) |

Model |

| Wheat flour | 1 | 250 | Wet | 3200 IT | DH-1200-1S |

| Flour | 0.6 | 24 | Dry | 1500㎏ | DH-1000-1S |

| Rice flour | 0.5 0.8 | 100 | 300 ㎏ | DH-1000-1S | |

| Pollen | 0.4 | 12 | 100㎏ | DH-1500-1S | |

| Skimmed milk powder | 0.57-0.7 | 24 | 3000㎏ | DH-1200-1S | |

| Whole milk powder | 0.57-0.8 | 12 | 1600㎏ | DH-1000-1S | |

| Sugar powder | 0.5-0.8 | 100 | 200㎏ | DH-800-1S | |

| Corn starch | 0.6 | 40 | 1600㎏ | DH-1000-1S | |

| Medicine powder | 0.8 | 80 | 550㎏ | DH-800-1S | |

| Polyethylene powder | 0.45 | 48/100 | 100㎏ | DH-800-2S | |

| Lead powder | 11.34 | 10/80 | 1000㎏ | DH-1000-2S | |

| Copper powder | 2 | 100 | 70㎏ | DH-800-1S | |

| Iron powder | 3 | 400 | 230㎏ | DH-800-1S | |

| Aluminum powder | 0.9/1.2 | 80/120 | 350㎏ | DH-800-2S |

1. Grains and grains:

Oat kernel 14 mesh, cassia seed 16 mesh, corn chopped 16 mesh, rice 12-14 mesh, black bean 5 mesh, red bean 5 mesh, soybean 6 mesh, barley 8 mesh, mung bean 10 mesh, buckwheat 12 mesh, black rice 14 mesh, brown rice 14 mesh, sesame 24 mesh, millet 24 mesh

2. Powder:

Traditional Chinese medicine powder is generally 60 mesh, coarser 40 mesh, oral 60-80 mesh, corn flour 30 mesh, almond powder 30-40 mesh, flour 50-60 mesh, cereals 30-40 mesh, Panax notoginseng powder 80-100 mesh, pearl Powder 120-150 mesh, coffee powder 100-120 mesh

3. Liquid:

Filter soy milk, honey 60-120 mesh, tea water 80-150 mesh

4. Other categories:

Pepper 6 mesh, insect dung screen 30 mesh, cat litter 30-40 mesh, pepper seed 8-10 mesh, edible oil, mechanical oil residue 150-200 mesh, yellow mealworm spawning screen 12 mesh

-

What is the difference between ultrasonic sieving machine and vibratory sifter

Many people have the same questions about Ultrasonic Sieving Machine and Vibratory Sifter ...

-

Installation and commissioning of the Vibratory sifter for plastic pellets

⑴ Vibratory sifter for plastic pellets production line installation There should be a ...