Ultrasonic Vibrating Screen

Callback

| Screen size: | 80-600 mesh |

| Vibration frequency: | 36000 times/sec |

| Capacity: | 100-5000kg/h |

Screen powders on meshes as fine as 20 microns without blinding or blocking

Prevent clogging and reduce the time to clean the net

The accuracy can be increased by 10%-70%, and the output can be increased by 0.5-10 times

-

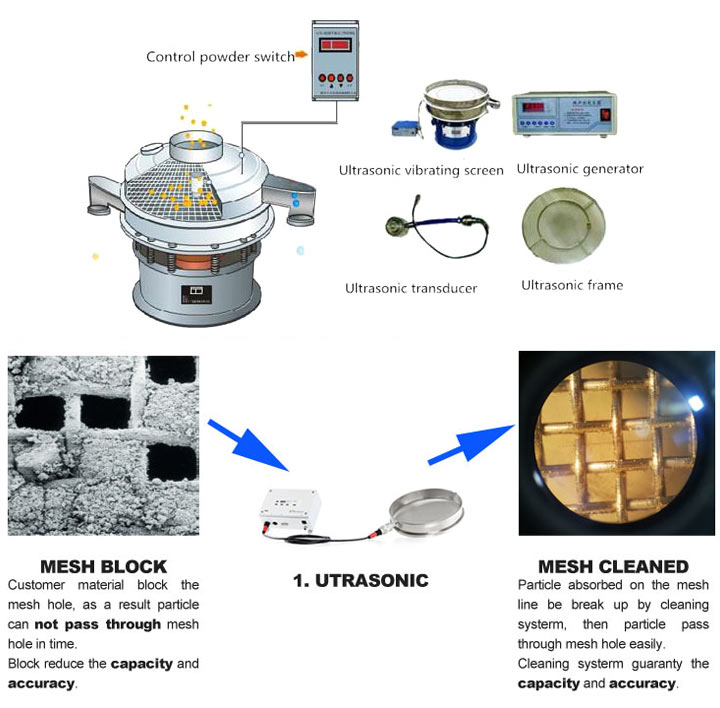

1. What is an ultrasonic vibrating screen

ltrasonic vibrating screen can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer, and convert it into 36KHz mechanical vibration. The mesh will not be clogged and it is easier to sift powder. The system increases screening capacity by a factor of 10, increasing productivity while allowing separations down to 20m (#635 mesh). Really solve the screening problems of strong adsorption, adhesion, viscosity, high static electricity, high density, ultrafine powder and other characteristic materials.

The material of the ultrasonic vibrating screen is divided into three types: carbon steel, stainless steel and all stainless steel. The number of layers of the screen surface is divided into 1 layer, 2 layers, 3 layers, 4 layers, and 5 layers. materials of different particle sizes.

2. Types of ultrasonic vibrating screen

Built-in ultrasonic vibrating screen: The ultrasonic transducer is installed at the bottom of the screen. When screening some corrosive materials, it will seriously damage the use of the transducer and affect the output frequency. There is no way to screen corrosive materials. But it can be used in the food industry to avoid cross-contamination.

External ultrasonic vibrating screen: The ultrasonic transducer is installed outside the screen frame and will not come into contact with the material, avoiding damage to the transducer when screening some corrosive materials, and improving the service life and output of the screen machine.

Working Priciple of ultrasonic vibrating screen

Ultrasonic vibrating screen is an ultrasonic screening system added on the basis of ordinary vibrating screens. It can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer and convert it into 36KHz mechanical vibration. The generated ultrasonic waves make the screen mesh With high-frequency vibration, the vibration frequency can reach 36,000 times per second, which can make the fine powder materials form a micro-suspension state on the screen, and can pass through the screen faster, without generating static electricity and sticking to the screen, while achieving screening and cleaning The effect of the screen.

Due to the unique screening principle of the ultrasonic vibrating screen, it is easy to screen the fine powder materials under the condition of low amplitude and high frequency vibration. The penetration rate can effectively screen 600 mesh ultrafine powder.

3. Product advantages and application scope

Ultrasonic vibrating sieve is an ultrasonic system (ultrasonic power supply, ultrasonic transducer, ultrasonic vibrating screen frame) added on the basis of ordinary vibrating sieves. The ultrasonic frequency is applied to the sieve, which can separate 20m (#635 mesh) fine powder , the following will introduce the use of ultrasonic vibrating screen for you:

1. Ultra-fine powder screening: truly solve the screening problems of strong adsorption, adhesion, viscosity, high static electricity, high density, ultra-fine powder and other characteristic materials.

2. Solve the blockage of the screen: change the vibration frequency of the ordinary screen machine, the vibration frequency is 36000 times/min, so that the vibration frequency of the material in the same unit time increases, thereby increasing the number of times the material passes through the screen hole in the same time, and the material is easier Through the net, improve the permeability, so as to achieve the purpose of screening and cleaning the screen.

3. Cost reduction: Due to the elimination of screen clogging, the product quality remains consistent throughout the production process, and there is no need to stop to clean the screen, reducing the risk of downtime and reducing production costs.

4. Increase the output: Since the screen will not be blocked, the screen can be cleaned without stopping the machine, and the output can be increased by 0.5-10 times.

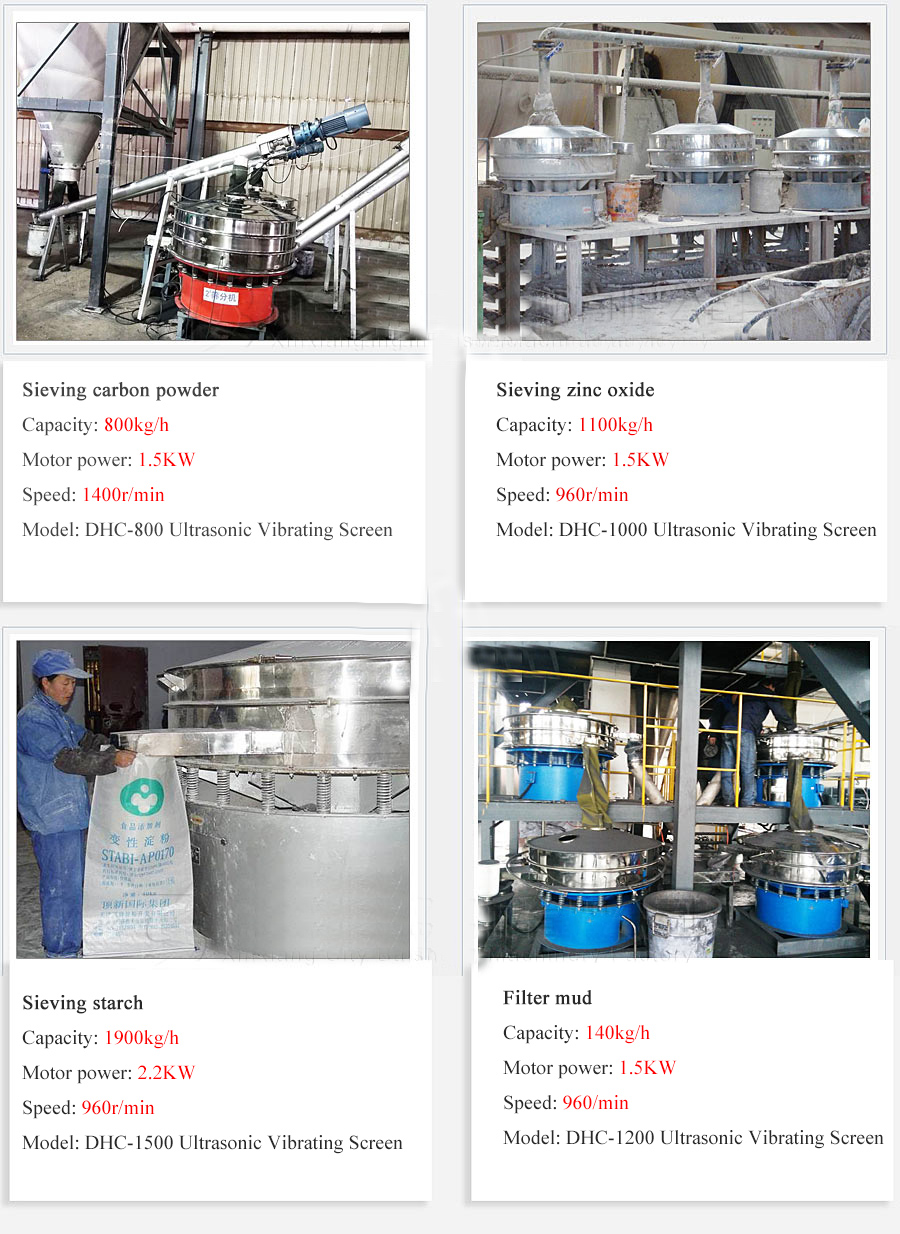

Compared with the ordinary vibrating screen, the ultrasonic vibrating screen can improve the screening accuracy by 1-70%, and the output can be increased by 0.5-10 times. It solves the problem of strong adsorption, static electricity, strong viscosity and high density to solve the problem of ultrafine powder screening. At present, it has been widely used in the screening of flour, graphite powder, rubber powder, quartz sand powder, metal powder, powder coating, fluorescent powder and other fine powders.

4. Reference video for screening materials

-

Sieving graphite powder

-

Sieving seaweed fiber

Comparison of screening effect between ordinary vibrating screen and ultrasonic vibrating screen

| Model | Test Material | Mesh Size | Vibrating Screen | Ultrasonic Vibrating Screen |

| 1000 | Silicon carbide | 500 mesh | Cannot be sieved | 1500 kg/h |

| 1000 | Tungsten powder | 600 mesh | 15 minutes without sifting out fine powder | 30kg/hour |

| ⌀1000 | Vitamin C Powder | 100 mesh | 1 kg/hour | 120-150 kg/h |

| 600 | Pollen | 400 mesh | 15 minutes without sifting out fine powder | 15 minutes sieve |

| 1000 | Cobalt powder | 400 mesh | 10kg/hour | 300 kg/h |

| 1000 | NdFeB powder | 300 mesh | 32.2% sieve residue 30 minutes | 30 minutes to sieve out 6.9% of the residue |

| 1000 | Gold steel sand powder | 300 mesh | Cannot be sieved | 1300 kg/h |

| 1200 | Antimony trioxide | 80 mesh | 700 kg/h | 2000kg/hour |

5. Technical parameters of ultrasonic vibrating screen

Ultrasonic vibrating screen has many models and special products (customized according to the nature of materials) to choose from according to different output requirements and material characteristics:

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW |

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW |

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW |

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW |

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW |

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW |

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |

6. Ultrasonic vibrating screen structure

Ultrasonic vibrating screen frame: It is composed of an outer grid frame and a resonance ring.

Screen: suitable for 10 mesh-635 mesh

High-frequency connection line: the cable used for the connection between the ultrasonic oscillator and the ultrasonic resonant power supply.

Ultrasonic vibrating screen power supply: LCD display window, 38KHZ high-frequency high-power ultrasonic resonance power supply. The built-in computer chip can automatically track the whole digital frequency according to the different states of the ultrasound, without manual adjustment, and the operation is convenient and simple. Long-time working oscillator has low heat output and stable working condition.

Ultrasonic transducer: high-performance ultrasonic conversion device, also known as ultrasonic vibrating head, ultrasonic vibrating head, is divided into two installation methods: external type and internal type.

Connector: Aviation connection plug-in.

Options

Waveguide System: Our waveguide system is individually designed for your screen frame, depending on the size of the frame, we can insert a variable number of waveguide rings into the frame to ensure optimal ultrasonic performance.

Ultrasonic Transducer: Allows to use one generator to excite multiple ultrasonic transducers at the same time, even screens with different resonance characteristics can be excited at the same time due to the change of frequency. For large screen frames, a single large or multiple waveguide rings can be processed using multiple ultrasonic transducers excited by one generator.

If you still have the following questions:

How should my material be used?

What is the model of the machine I need?

What mesh size and how many layers of screen should I choose?

Can my current voltage meet the usage requirements?

Can the product be specially designed according to my material?

wait for the question...

You can consult us, we will have professionals to help you.

Related cases

-

Suitable for impurity removal and filtration of 200-600 mesh ultra-fine powder

-

Granules, powders, and paddle materials can be used

-

How to select the ultrasonic vibrating screen

The ultrasonic vibrating screen is equipped with an ultrasonic device on the basis of the rotary vibr ...

-

What is the difference between ultrasonic sieving machine and vibratory sifter

Many people have the same questions about Ultrasonic Sieving Machine and Vibratory Sifter ...

-

What are the functions and characteristics of ultrasonic sieving machine

he main feature of the ultrasonic sieving machine is the ultrasonic system. The exciting force it emits ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.