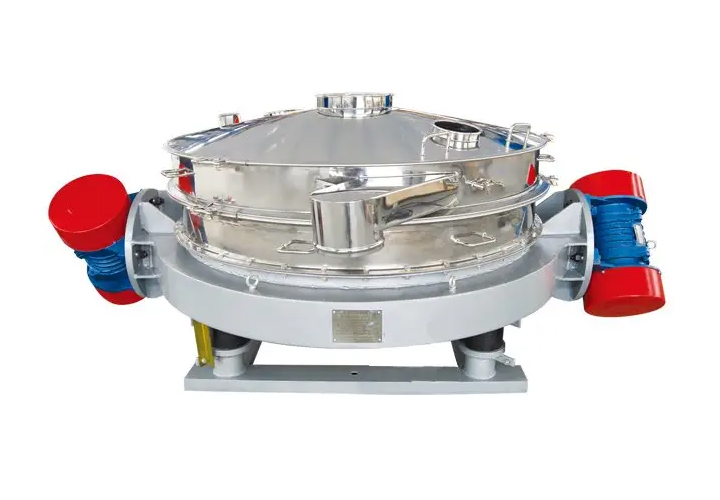

Industrial Sieving Machine

Callback

| Mesh Size: | 2-500 mesh (0.028mm) |

| Capacity: | 100-3300kg/h |

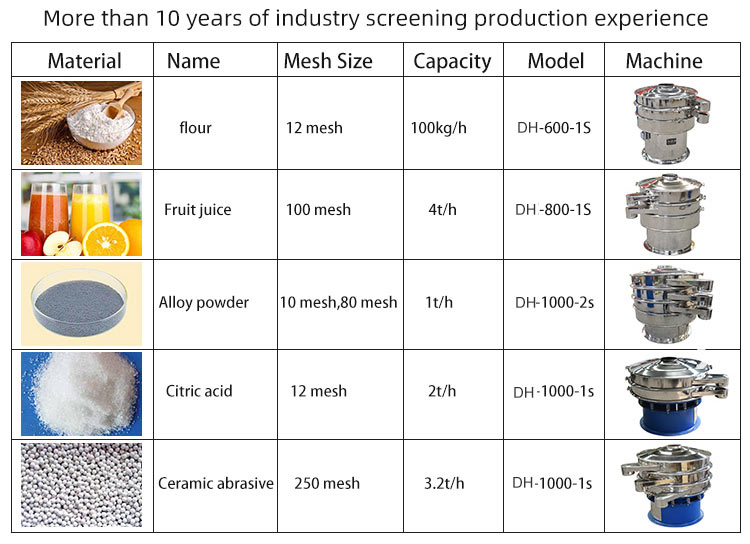

Common Applications: Removal of contaminants from flour, sugar, pharmaceutical powders, powder coatings, etc., and accurate grading of multiple sizes

Application industry: food and beverage, pharmaceutical, chemical, powder coating, plastic, metal powder, etc.

Introduction of industrial sieving machine

Industrial sieving machine is a sieving machine for separating powder, granule and liquid slurry, it can accurately remove oversized pollutants in powder, granule, very suitable for secondary side of production equipment from primary side to finished product inspection and Screen your material, you can achieve the separation of 5 different size materials in one operation, it is made of Q235 carbon steel or SUS304 stainless steel (or SUS316 on request), with unbalanced weight motor, which can generate three-dimensional movement, making Product sieving is very efficient and adjusting the unbalanced weight can adjust the product behavior on the screen and the sieving speed.

Our industrial sieving machine, offers 8 different sizes of industrial sieving machine - 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm and 2000mm diameter to meet your specific production needs. It allows a throughput of 100 to 5,000 kg/h, depending on the product, mesh size and the feed flow of the machine. It is suitable for sieving from 36 microns to 25 mm. The oversized spouts can also be rotated around the circumference to any position for easy material collection, and the units can be easily moved for use anywhere on the factory floor.

Purpose of industrial sieving machine

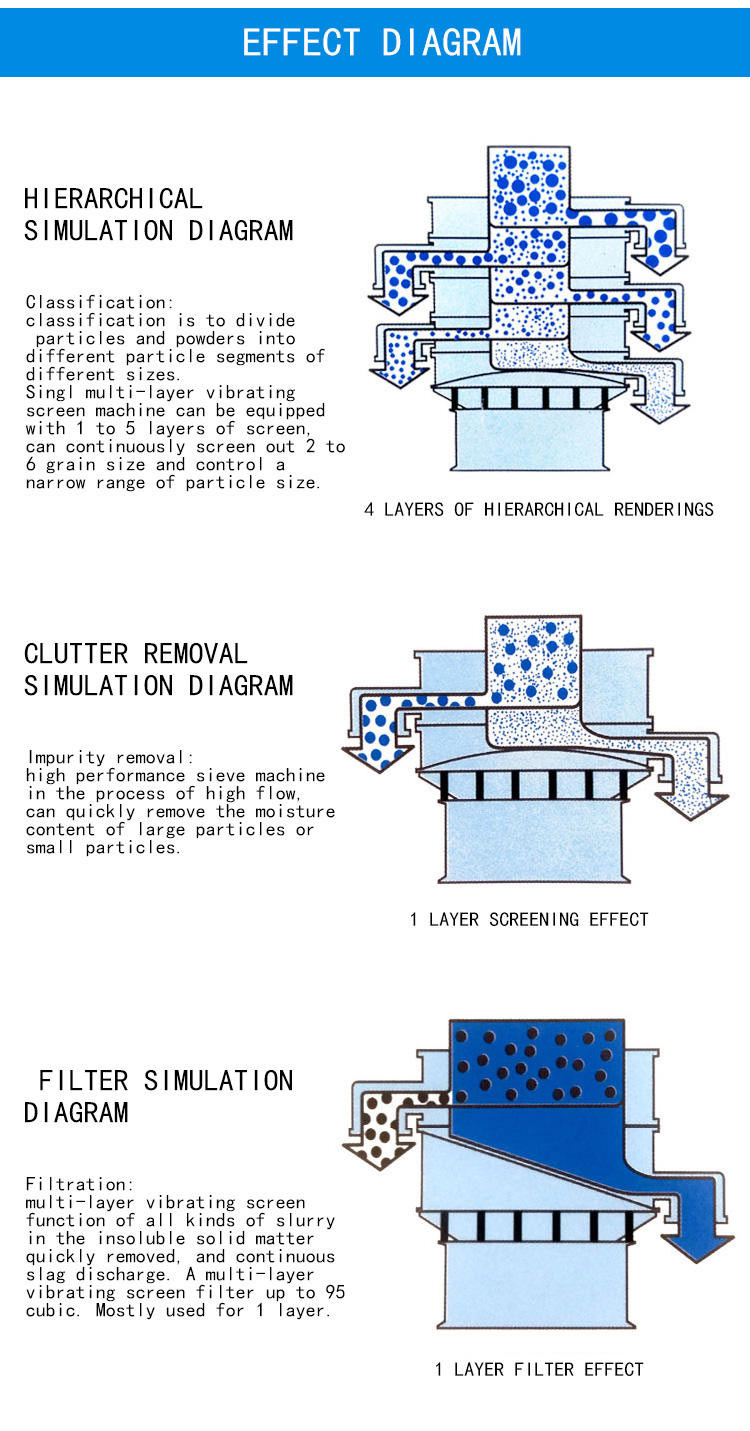

1. Removal of impurities: high fluidity powder processing, fast removal of large particles or fine powder with low content.

2. Grading and screening: Continuously select mixed materials of different particle sizes and classify them into different particle size grades. Can be divided into one, two, three, four and so on. What's more, only one operation can continuously filter up to 5 stages of product separation.

3. Solid-liquid separation: quickly remove insoluble solids in various slurries, and remove unqualified impurities or suspended solids in slurries.

Common types of industrial sieving machine

-

Pharmaceutical Vibro Sifter

It is specially used in the pharmaceutical industry to remove large agglomerates and fine powders in drug particles, to ensure uniform and complete particles, and to meet pharmaceutical-grade hygiene standards.

-

Food Grade Vibro Sifter

It can divide various food raw materials (such as flour, milk powder, soybean milk, corn, spices) into several particle size grades according to different components, or remove fine powder, solid particles or agglomerates and other impurities.

-

Plastic Vibrating Screen

Made of polypropylene material, acid and alkali corrosion resistance, anti-oxidation, used for screening operations of acid, alkali and corrosive materials.

Featured videos

Benefits of our industrial sieving machine

1. Wide screening range: It can screen any particles, powders, and slurries (mucuses). The screening can be as fine as 500 mesh (0.028mm), and the filtration can be as small as 5 microns.

2. Grading and screening, 1-5 layers of screens can be configured, and 2-6 grades of sorting or filtering can be carried out at the same time.

3. Not easy to block: there is a bouncing net cleaning device installed under the screens of each layer. By continuously hitting the screens, the materials can be screened smoothly and the problem of material blockage can be effectively avoided.

4. High throughput: automatic discharge, no material storage in the machine, no dead angle in the grid structure, and Dahan Machinery's screen machine with the same screen surface has a larger capacity than other types of screen machines.

5. Convenient replacement of the screen: the screen has a unique sub-network design, the screen has a longer life and higher efficiency, and two people can complete the screen change within 3 to 5 minutes, which saves 30 to 60 minutes compared with other types of screens. Maximize the value of equipment use.

6. Vibration without mechanical transmission: The three-dimensional vibration generated by the new vibration source of the screening machine is powerful and stable without mechanical transmission. The equipment can be installed in any desired position and is easy to move.

Related cases of circular sieve

| Materials | Processing method | Screen/(mesh/inch) | Capacity/(kg/hour) |

| Milk powder | Dry | 16.2 | 2000 |

| Granulated sugar | 4.2 | 5000 | |

| Granulated sugar | 4.2 | 5000 | |

| Chinese Medicine/Pesticide |

80/100/150 | 1400 | |

| Resin powder | 40/60/80 | 1000 | |

| Grinding powder | 40/60/250 | 1200 | |

| Pigment powder | 20 | 4000 | |

| Iron powder | 60/80/120 | 2500 | |

| Copper powder | 80 | 2000 | |

| Stone copper powder |

40/65/200 | 2000 | |

| Aluminum silver powder |

60 | 1500 | |

| Starch | 80 | 1200 | |

| Rare metal powder | 100/1500/200 | 1200 | |

| Activated carbon | 40/60 | 1000 | |

| Coating | Wet | 100 | 7500 |

| Sub-slurry | Wet | 120 | 6000 |

| Food processing wastewater |

Wet | 20 | 3500 |

| Papermaking clay mud |

Wet | 150 | 3500 |

| Foundry sand | Dry | 8 | 10000 |

Technical parameters of industrial sieving machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Customized recommendation

Dahan Machinery offers a range of industrial and sanitary screening equipment to meet your requirements in a variety of applications. Our classifying sieves and separators accurately separate your powders into different sized particles. In addition, we can customize for you according to various industries to meet your unique requirements.

Optional equipment

1. Multi-layer screen: 1-layer, 2-layer, 3-layer, 4-layer, 5-layer screen can be selected, Separate dry/wet materials into 2-6 different sizes

2. Ultrasonic deblinding system: It enables sieving on finer meshes (down to 20 microns) without any blocking or blinding of the aperture. It also increases throughput and reduces cleaning times.

3. Screen lifter: Utilizing two high-performance pneumatic piston assemblies, multiple screens can be quickly and safely lifted to a height for comfortable access to screens that need to be inspected or replaced.

4. Quick Clamping System: Provides consistent and even clamping pressure, which overcomes the problems associated with frequent re-adjustment of the lower clamp.

5. Iron removal device: It is designed to provide the ultimate solution to control iron pollution when inspecting and sifting dry powder.

In addition, our industrial sieving machine can be customized according to the needs of different industries, such as mobile type, edge type, gate type, explosion-proof type, etc.

The discharge port and the feed port can adopt different shapes according to the actual situation on site.

Related cases

| Food & Medicine industry | Metal, Metallurgy & Mining | ||||||||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Milk powder | 1 | 250 | DH-1200-1S | Wet | 3200 IT | Graphite | 1.2 | 16/40/80 | DH-1000-3S | Dry | 1400㎏ |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ | Lead powder | 11.34 | 10/80 | DH-1000-2S | 1000㎏ | |

| Soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT | Iron powder | 3 | 400 | DH-800-1S | 230㎏ | |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ | Emery | 4 | 60 | DH-1000-1S | 300㎏ | |

| Medicine powder | 0.8 | 80 | DH-800-1S | Dry | 550㎏ | Aluminum powder | 0.9/1.2 | 80/120 | DH-800-2S | 350㎏ | |

| Kiln Industry | Pollution Treatment & Other Industries | ||||||||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Spray soil particles | 2 | 10 | DH-1000-1S | Dry | 18000㎏ | Waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000IT |

| Mica | 0.8 | 200 | DH-800-1S | 110㎏ | Dyeing and steaming wastewater | 1 | 150 | DH-1000-1S | 22000IT | ||

| Feldspar | 2.5 | 60/100 | DH-1000-2S | 350㎏ | Waste oil | 0.9 | 100 | DH-1000-1S | 3800IT | ||

Selection for different industries

Different industries can adopt special customization for industrial sieving machine:

1. Food and pharmaceutical industries: Because the food and pharmaceutical industries require high hygienic standards. Therefore, it is recommended to use stainless steel 304 stainless steel industrial sieving machine.

2. Chemical industry: Because there are not only some materials with weak acidity, but also some materials with strong alkalinity in the chemical industry, there will be different designs.

(1) For the screening of materials with low acidity, it is recommended to use: plastic industrial sieving machine, which is made of pp material, which has strong acid resistance, so it is not a problem to screen acidic materials.

(2) For the screening of materials with strong alkalinity, it is recommended to use: plastic industrial sieving machine, which is not only suitable for the screening of acidic materials, but also for alkaline materials.

3. Paper industry: The paper industry is mostly slurry, so the industrial sieving machine is generally designed to be heightened to prevent the slurry from splashing out.

4. Metal metallurgy industry: Most of them are metal powders. Ultrasonic deblinding devices can be installed for light powders with high static electricity and easily clumping together to prevent screen clogging and increase screening output. According to data, the output can be increased by 10 times.

-

Screening for powder, granular or small block materials, such as flour, concrete ...

-

One of precised powder sieve,suitable for any particle ...

-

Suitable for impurity removal and filtration of 200-600 mesh ultra-fine powder ...

-

Types of rotary Industrial sieving machine

Industrial sieving machine is a high-precision screening machine, whether the material is dry or wet, ...

-

Flour Sifter Industrial for Sieving Flour

The purpose of flour sifting is mainly to remove impurities and sieve loose, so for different purposes ...

-

Pharmaceutical industry's selection requirements for pharmaceutical vibro sifter

Pharmaceutical vibro sifter Common screening machines are vibrating screens and linear vibrating screen ...

-

Special screening equipment for sugar industry-Sugar Mill Vibro Sifter

The sugar mill vibro sifter is a high-precision fine powder screening machine. According to the shape an...

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.