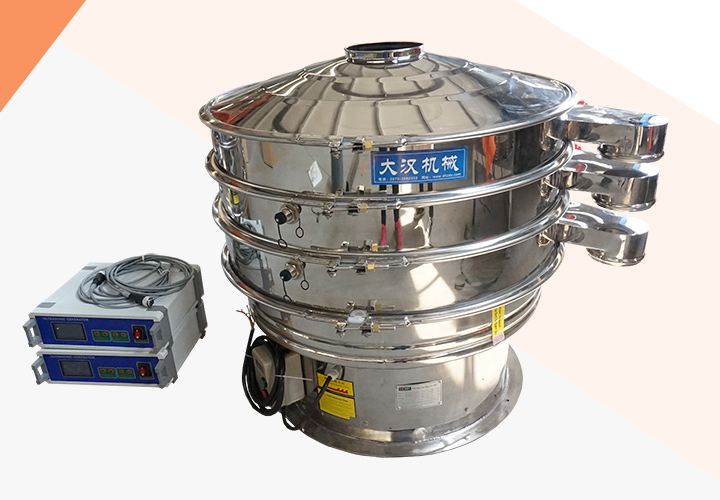

Ultrasonic Sieving Machine

![[field:title/]](/uploads/211112/1-211112155U5155.jpg)

Callback

| Screen size: | 80-900 mesh |

| Output: | 100-5000kg/h |

| Number of layers: | 1-5 layers |

Use ultrasonic frequency to vibrate the mesh to prevent the apertures from being blocked

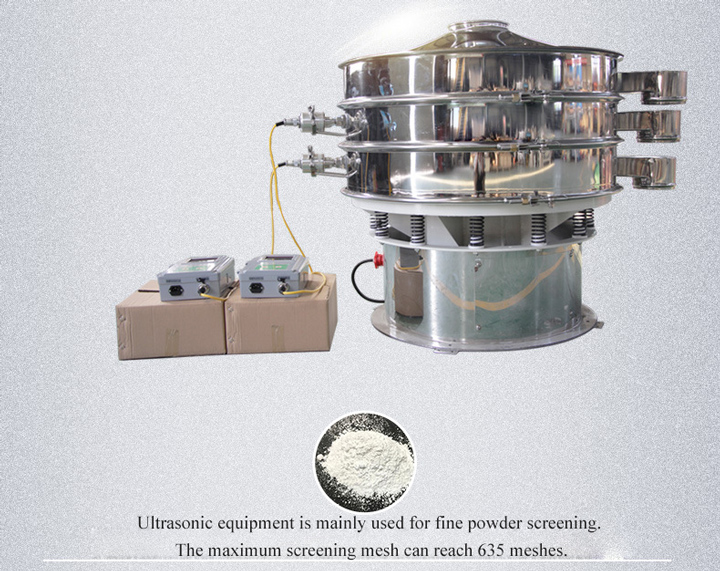

Allows a separation accuracy as low as 20 microns (#635 mesh)

Increase screening capacity by up to 10 times

Introduction of ultrasonic sieving machine

Ultrasonic sieving machine adds an ultrasonic blinding system to the sieving machine, which uses ultrasonic frequencies to vibrate the net. This prevents the holes from being clogged and makes it easier to screen the powder. The system can increase the screening capacity by up to 10 times, thereby increasing productivity, while allowing separation accuracy as low as 20 microns (#635 mesh).

The deblinding system can be installed on a new or existing vibrating screen for easy integration into your production line. Preventing the screen from being overloaded not only reduces production downtime, it also reduces the time required to clean the mesh.

Benefits of ultrasonic sieving machine

1. It has a better effect on materials that are difficult to screen, such as strong adsorption, easy agglomeration, high static electricity, high precision, high density, and light specific gravity.

2. Compared with ordinary sieving machine, the screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

3. It can be used in single layer or multiple layers, and a set of intelligent ultrasonic generator uses three transducers at the same time.

4. While achieving high-precision and high-mesh screening, it effectively controls the concentration of particle segments.

5. With self-cleaning function, when screening >500 mesh, there is no mesh clogging, no screening efficiency attenuation, and high signal uniformity.

6. The output waveband of the numerical control power supply is transmitted to the surface of the screen 360,000 times per minute through the transducer.

Working principle of ultrasonic sieving machine

Ultrasonic sieving machine converts 220V, 50Hz or 110V, 60Hz electrical energy into 18KHz high-frequency electrical energy, which is input into an ultrasonic transducer to turn it into 18KHz mechanical vibration. The materials are not only subjected to the force of the three-dimensional rotary vibrating screen during screening. The force that causes the material to make up and down, horizontal and inclined three-dimensional movements on the screen surface is also subjected to the high frequency and low amplitude force exerted on the screen surface by the ultrasonic system, so as to achieve the purpose of screening and cleaning.

Featured videos

-

Sieving turmeric powder

-

Sieving silica powder

Structure of ultrasonic sieving machine

The structural composition mainly includes:

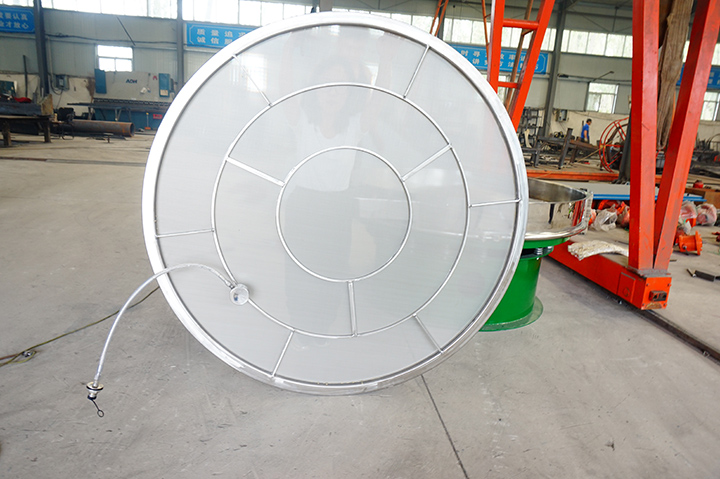

1. Ultrasonic grid: It is composed of an external grid and a resonance ring.

2. Screen: suitable for 10 mesh-635 mesh

3. High-frequency connection cable: the cable used to connect the ultrasonic oscillator and the ultrasonic resonant power supply.

4. Ultrasonic resonance power supply: LCD display window, 38KHZ high frequency and high power ultrasonic resonance power supply. The built-in computer chip can automatically track the whole digital frequency according to the different states of the ultrasound, without manual adjustment, and the operation is convenient and simple. Long-time working oscillator has low heat output and stable working condition.

5. Oscillator: high-performance ultrasonic conversion device.

6. Connector: Aviation connection plug-in.

Technical parameters of ultrasonic sieving machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Difference between Ultrasonic sieving machine and ordinary sieving machine

| Materials | ordinary sieving machine | Ultrasonic sieving machine | Test model | ||

| Mesh number | Test results | Mesh number | Test results | ||

| Silicon carbide | 500 | Unable to sieve | 500 | 1000kg/h | 1000mm |

| Tungsten carbide powder | 600 | No fine powder is sifted out in 15 minutes | 600 | 30kg/h | 1000mm |

| Vitamin C powder | 100 | 1kg/h | 100 | 120kg/h | 1000mm |

| Pollen | 400 | No fine powder is sifted out in 15 minutes | 400 | Approximately 20% fine powder can be sieved out in 15 minutes, and can be more finely and effectively classified | 600mm |

| NdFeB powder | 300 | 30% sieve residue in 30 minutes | 300 | 7% residue on sieve in 30 minutes | 600mm |

| Nickel and cobalt powder | 325 | Screened 3 times to meet the requirements | 400 | The sieve meets the requirements once | 800mm |

| Phosphor | 500 | Sieving capacity 90kg/h | 500 | Sieving capacity 300kg/h | 800mm |

| Zinc powder | 325 | Sieving capacity 68kg/h | 325 | Sieving capacity 300kg/h | 800mm |

| Iron powder | 100 | Sieving capacity 96kg/h | 100 | Sieving capacity 300kg/h | 800mm |

| Seasoning powder | 60 | Sieving capacity 500kg/h | 60 | Sieving capacity 1000kg/h | 1000mm |

| Resin powder | 200 | Sieving capacity 340kg/h | 200 | Sieving capacity 745kg/h | 1000mm |

| Sweet potato starch | 200 | Sieving capacity 400kg/h | 200 | Sieving capacity 1500kg/h | 1000mm |

| Kaolin | 200 | Sieving capacity 38kg/h | 200 | Sieving capacity 200kg/h | 1000mm |

Application of ultrasonic sieving machine

Ultrasonic sieving machine is suitable for silicon carbide, electromagnetic powder, anode material, laser powder, carbon powder, powder coating, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, cobalt powder, nickel powder, quartz powder, malt powder, spore powder, resin Fine powders such as powders and abrasives.

| Material | Mesh | Ultrasonic sieving machine | Model |

| Capacity(kg/h) | |||

| Phosphor | 500 | 300 | 800mm |

| Zinc powder | 325 | 300 | 800mm |

| Seasoning powder | 60 | 1200 | 1000mm |

| Resin powder | 200 | 745 | 1000mm |

| Sweet potato starch | 200 | 1500 | 1000mm |

| Iron powder | 100 | 300 | 800mm |

| Kaolin | 200 | 200 | 1000mm |

Related cases

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers, and 6 different grades of graphite ...

-

What are the functions and characteristics of ultrasonic sieving machine

The main feature of the ultrasonic sieving machine is the ultrasonic system. The exciting force it em ...

-

What is the difference between ultrasonic sieving machine and vibratory sifter

Many people have the same questions about Ultrasonic Sieving Machine and Vibratory Sifter . What is t ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.