Circular Vibrating Sieve

Callback

| Model: Ø 400- Ø 2000 mm | Screen size: 2-500 mesh |

| Capacity: 100-3300kg/h | Level: 1-5 layers |

Eliminate oversize and contamination in powder or liquid slurries

Closed design can eliminate dust and fumes

Provides up-to 5 levels of gradation for precise particle size distribution in one single operation.

Introduction of circular vibrating sieve

Circular vibrating sieve screens products by using a customized layered sieve and 3D motion, it can be used to screen dry powder or granular products as well as wet products and liquids, it can eliminate foreign matter in products through continuous filtration, only 1 operation is required Performs up to 5 stages of product separation.

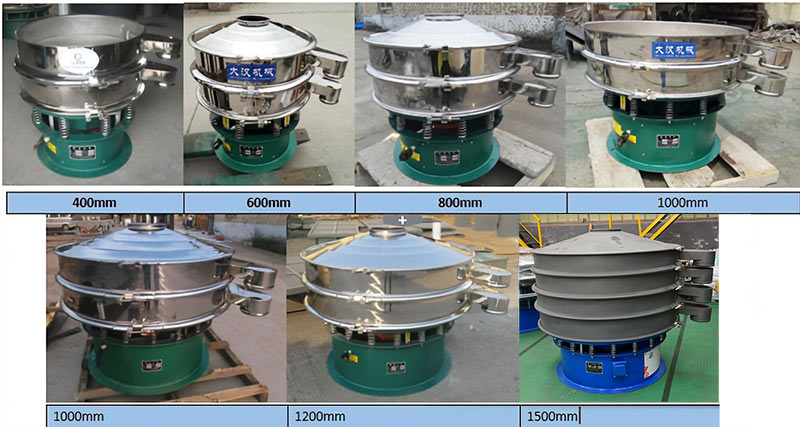

Circular vibrating sieve can screen up to 500 meshes and has various sizes (from 400mm to 2000mm) to meet the screening needs of different industries. The output is from 100 to 3300kg/h. Ordinary type), gate type, edge type, etc., are widely used in a series of applications, including screening pharmaceutical powder, various food powder and powder coating industries.

Application of circular vibrating sieve

Circular vibrating sieve is used to screen powder, fine particles or slurry materials.

Grading and screening: Continuously sort mixed materials of different particle sizes into products of different particle size grades, and one material can be sorted into 2-6 different specifications.

Screening impurities: suitable for high-flow powder material treatment, quickly remove large particles or fine powder with small content.

Solid-liquid separation: quickly remove insoluble solids in various slurries.

Separation of slurry impurities: remove unqualified impurities from the slurry.

Types of circular vibrating sieve

-

Ordinary circular vibrating sieve

Can remove oversized particles and contaminants as an effective way to protect ingredients and final products from contamination and caking.

-

Ultrasonic circular vibrating sieve

An ultrasonic system is installed, which is suitable for sieving 20 micron fine powder, which can solve the problem of mesh blocking while sieving materials.

-

Gas Protection Vibro Sifter

Closed systems can be purged with inert gas to isolate contamination-sensitive powders from ambient air and moisture, reducing powder cross-contamination.

Working priciple of circular vibrating sieve

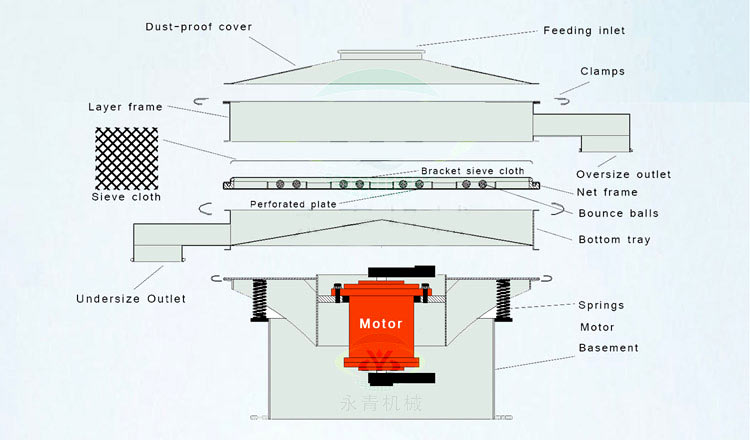

Circular vibrating sieve is mainly composed of feed inlet, dust cover, outlet, beam ring, screen mesh, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, machine base and other parts.

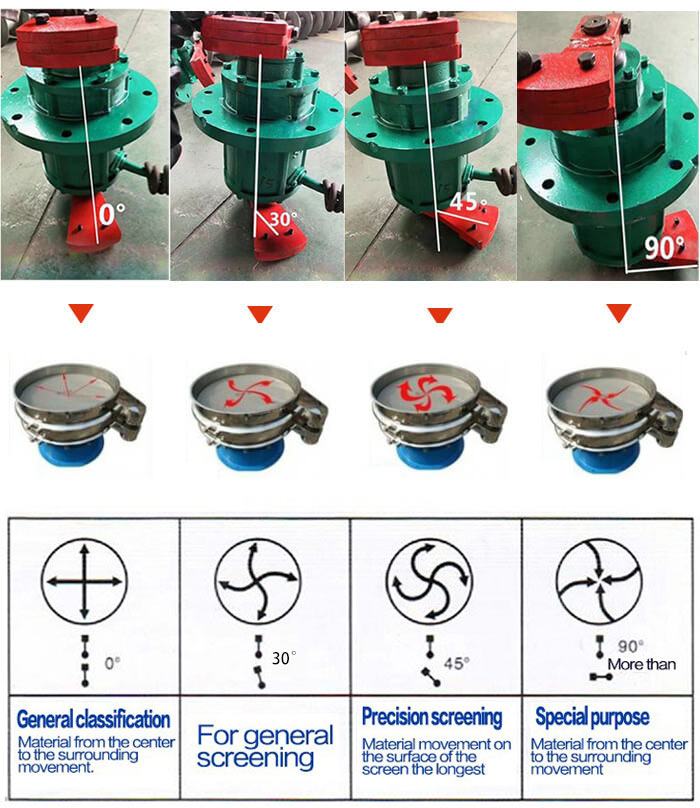

When the sieve machine is started, the rotating motion of the motor is transformed into horizontal, vertical and inclined three-dimensional motion, and then this motion is transmitted to the screen surface, so that the material smaller than the sieve surface aperture falls to the lower layer through the sieve hole and becomes the under-sieve material, which is larger than the sieve surface. The material with the aperture of the screen surface is discharged from the discharge port after continuous jumping motion, so as to achieve the purpose of screening. The user can change the movement track of the material on the screen surface by adjusting the phase angle of the upper and lower weights.

Benefits of circular vibrating sieve

1. It is suitable for sieving from 36 microns to 25 mm, for the separation process of solids in liquids, for the classification of different particle sizes in the same product or for safety screening to eliminate foreign matter, etc.

2. Provide a variety of sizes (φ400mm-φ2000mm) and options to meet your requirements, the maximum capacity can reach 3300kg/h.

3. It can be selected with 1, 2, 3, 4 or 5 decks, allowing up to 6 products to be separated at the same time.

4. Due to its compact nature, these sieves can be easily installed anywhere on the production line, occupying less than half the height of traditional sieves, but with greater screening capacity.

5. Its closed design prevents harmful dust or smoke leakage.

Featured videos

Technical parameters of circular vibrating sieve

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Special Design

Our circular vibrating sieve supports customization. For example, if the site space is limited, we can increase or decrease the bottom bucket or upper frame accordingly. If the material contains iron, an iron remover can be added. If your material can't touch iron element, you can make it be made of PP material or plastic. If the material is too viscous and needs to be diluted, we can add a spray device, etc.

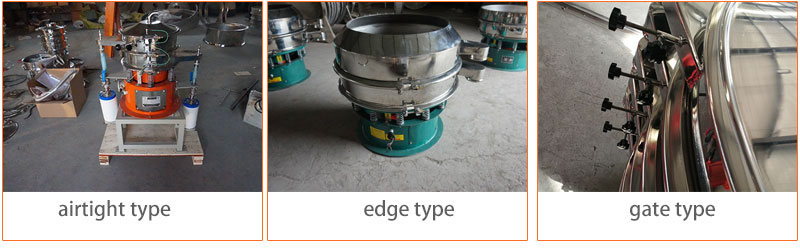

Airtight type: add gas protection device on the basis of circular vibrating sieve. It is installed for the properties of certain materials, such as certain materials that cannot be touched. Oxygen, carbon dioxide, 3D printing powder, metal powder, graphite powder, etc. are protected by inert gas during the sieving process, which can prevent the powder from oxidizing or deteriorating due to moisture absorption. Due to the sealed design, dust is also prevented from being too dense and exposed to the air. cause an explosion.

Edged type: The feeding port is designed to be heightened and protected. The edged design can increase the feeding amount, prevent the material from splashing, and observe the condition of the screen.

Gate type: The design of the customs gate can control the residence and screening time of materials on the screen, ensure the processing accuracy of difficult-to-screen materials (viscous and fine materials), and increase the processing capacity.

Structure of circular vibrating sieve

Dust cover: to prevent the escape of dust.

Vibration motor: a vertical vibration motor is adopted, and the power of the motor can be freely selected from 0.18KW to 4.0KW (the larger the diameter of the equipment, the greater the power of the motor used). For some special industries, explosion-proof vibration motors can be equipped.

Screen frame: A component that constrains the material so that the material can be produced within a certain range. The common materials are Q235 carbon steel and 304 stainless steel, and the thickness of the material is 2.0mm~3.0mm.

Brace ring: it is used to connect the bottom cone and the screen frame, the upper and lower screen frames, and also to prevent material leakage.

The parts of the screen that are in direct contact with the material are usually made of 304 stainless steel braided mesh.

Punching plate: lift the screen to prolong the service life of the screen, the commonly used material is 304 stainless steel.

Cleaning device: It can be divided into three types of cleaning devices: bouncing ball, ultrasonic wave, and rotating brush. Users can choose reasonably according to different production processes.

Bottom bucket: The part that supports the screen body and carries the vibrating motor, the thickness is 3mm~6mm, and the thickness is also determined according to the diameter of the equipment.

Vibration plate: It plays the role of fixing the vibration motor and connecting the screen body. The plate used is Q235 carbon steel with a thickness of 4mm~6mm.

Dimensions of circular vibrating sieve

| Model | A | B | C | D | E | F | H | I | Single Layer Height | DDuble Layer Height | Three Layer Height |

| DH-400 | 330 | 305 | 240 | 400 | 80 | 70 | 320 | 390 | 635 | 770 | 870 |

| DH-600 | 530 | 430 | 240 | 600 | 100 | 70 | 430 | 419 | 780 | 897 | 1013 |

| DH-800 | 680 | 580 | 240 | 800 | 125 | 90 | 540 | 435 | 850 | 1003 | 1152 |

| DH-1000 | 800 | 700 | 240 | 970 | 150 | 100 | 643 | 445 | 866 | 1015 | 1165 |

| DH-1200 | 985 | 855 | 400 | 1170 | 180 | 120 | 750 | 555 | 1035 | 1204 | 1373 |

| DH-1500 | 1190 | 1050 | 400 | 1470 | 200 | 120 | 930 | 556 | 1072 | 1249 | 1425 |

| DH-1800 | 1540 | 1440 | 400 | 1770 | 200 | 120 | 1025 | 680 | 1225 | 1394 | 1562 |

| DH-2000 | 1800 | 1720 | 400 | 1960 | 200 | 170 | 1260 | 680 | 1250 | 1420 | 1586 |

Available Options

| material |  |

|

| SUS304 stainless steel: it is mainly used in medicine, food and other industries. The characteristics of SUS304 high-quality stainless steel are high temperature resistance and high toughness. | Q235A carbon steel: mainly used in the chemical industry, Q235A carbon surface steel features: good toughness and plasticity. | |

| grid |  |

|

| Adhesive mesh frame: high cleanliness, the whole mesh frame has no dead angle, the screen is directly bonded to the mesh frame, and the screen wire head and corners are not retained; suitable for the food and pharmaceutical industries. | Sub-mother grid: suitable for materials with large specific gravity and strong elaboration, the screen is easy to replace and difficult, and the cost of screen replacement is low; suitable for chemical and metallurgical industries, etc. | |

| clear net |  |

|

| The use of the mesh frame blocking ball and the pinball is a common net cleaning device, which is generally used for 100-200 mesh screens. | Ultrasonic cleaning device: - - Generally used for 400-500 mesh screen, features: high efficiency, good cleaning effect. | |

| Seals |  |

|

| Rubber seals: mainly used in the chemical industry, high and low temperature resistance, good odor resistance and electrical insulation. | Silicone seals: mainly used in the food and pharmaceutical industries, with high adsorption performance and good thermal stability. |

Related cases of circular vibrating sieve

| Material | Proportion | Mesh | Model | Processing method | Capacity (kg/hr IT/hr) |

| Wheat flour | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| Soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Tofu | 1 | 120 | DH-1000-1S | Wet | 2500 IT |

| Sweetener | 0.7 | 40/80 | DH-800-2S | Dry | 320㎏ |

| Granulated sugar | 1.2 | 12 | DH-1500-1S | Dry | 8000㎏ |

| Pineapple juice | 1 | 100 | DH-1000-1S | Wet | 3000㎏ |

| Powdered sugar | 0.5-0.8 | 100 | DH-800-1S | Dry | 200㎏ |

| Corn starch | 0.6 | 40 | DH-1000-1S | Dry | 1600㎏ |

-

Used for the separation, classification, scalping, dedusting and selection of powder, granule and liquid.

-

The working principle of circular vibrating sieve

Vibrating screens are divided into Circular Vibrating Sieves, linear vibrating screens, rotary vibrating screens and other types. Today I want to introduce you to Circular Vibrating ...

-

How much is the medical Circular Sieve

The pharmaceutical Circular Sieve is an exclusive tool for screening materials in the pharmaceutical industry. It is widely used in the pharmaceutical industry. Many users do not kn ...

-

Circular sieve manufacturers

Because there are demand, there are many manufacturers of circular sieves on the market. Where are the circular sieves? According to the users choice in the factory gathering place ...

-

What kinds of common circular vibrating screens are there

Circular vibrating screen is a common type of vibrating equipment on the market. It is named after its circular shape. Do you know what types of circular vibrating screens are avail ...

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.