Stainless Steel Vibrating Sieve

![[field:title/]](/uploads/211113/1-21111315224Y60.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

High-temperature materials above 200℃

No black spots, easy to clean and disinfect

It also has anti-corrosion, anti-corrosion, acid and alkali resistance.

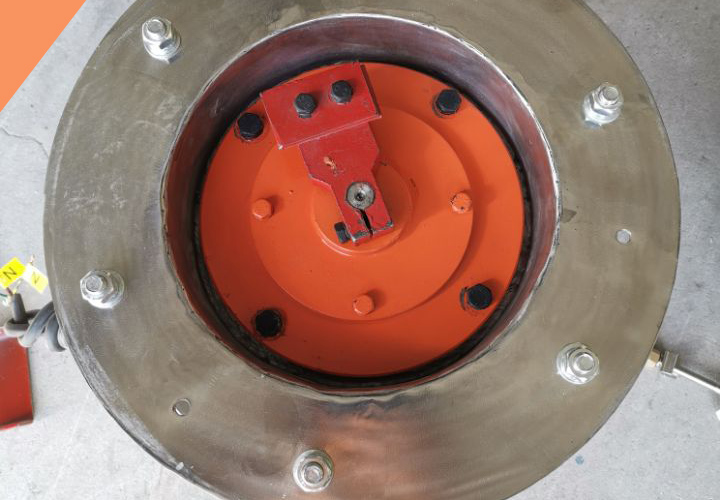

Introduction of stainless steel vibrating sieve

The stainless steel vibrating sieve, the parts in contact with the material and the dust cover are made of 304 stainless steel. The base part is made of Q235 carbon steel. It has anti-corrosion, acid and alkali resistance, and high temperature resistance above 200℃. The inside and outside of the stainless steel vibrating screen are polished and polished. It is not easy to rust and can avoid contamination of materials during the screening process. It is specially used in industries with strict hygiene requirements such as food and medicine.

Stainless steel vibrating sieve has 304, 304L, 310, 310L, 316, 316L grades of stainless steel. The higher the grade, the better the heat resistance and heat insulation performance of stainless steel. It can withstand high temperature material screening at 200℃-500℃ , In addition to good heat resistance and heat insulation performance, the stainless steel vibrating screen is less prone to rust after internal and external polishing and polishing, and good cleaning performance can prevent high-temperature materials from being contaminated.

Benefits of stainless steel vibrating sieve

1. It is made of stainless steel and can screen high-temperature materials above 200℃. At the same time, in addition to the characteristics of high temperature resistance, it also has anti-corrosion, anti-corrosion, acid and alkali resistance.

2. The sieve machine is polished, no burrs, no black spots, easy to clean and disinfect.

3. The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high.

4. The sealed structure can prevent the material from spilling during the screening process from polluting the screening environment, and it can also prevent external dust from entering the contaminated raw material

Working principle of stainless steel vibrating sieve

The stainless steel vibrating sieve uses a vertical vibrating motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the motor's rotating motion into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the sieve Screen the noodles. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Technical parameters of stainless steel vibrating sieve

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of stainless steel vibrating sieve

Food industry: flour, milk powder, starch, fish meal, rice noodles, vitamins, condiments, dextrin, beverages, fruit juices, sugar, soy sauce, pineapple juice, yeast

Chemical industry: paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder

Pharmaceutical industry: pharmaceutical intermediates, medical auxiliary materials, Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid and other ceramic abrasives

Metallurgical industry: aluminum silver paste, mud, kaolin, quartz sand, alumina, artificial black aluminum, graphite, silicon carbide, sprayed soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.

-

Suitable for screening and filtering of granules, powder, mucus and other materials

-

Suitable for impurity removal and filtration of 200-600 mesh ultra-fine powder

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.