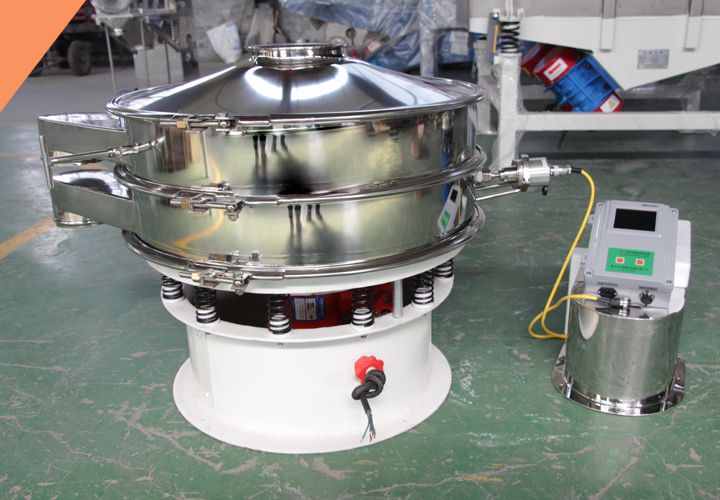

Vibratory Separator

Callback

| Mesh size | 2-500 mesh |

| Capacity | 100-3300kg/h |

Grades materials up to five differently-sized fractions

Full mesh coverage provides accurate grading and separation.

Can be used at multiple points on your production line

Introduction of vibratory separator

Vibratory separator, also known as a vibratory sieve or vibratory screener, is a machine used to separate and classify materials based on particle size. This equipment is commonly used in various industries such as food processing, pharmaceuticals, chemicals, and mining to efficiently separate particles and ensure product quality.

Typical uses of vibratory separator

Vibratory separators, also known as vibratory sieves or vibratory screens, have numerous uses across various industries. Here are some common applications of vibratory separators:

1.Particle Classification and Grading: Vibratory separators are widely used for particle classification and grading based on size. They can accurately separate materials into different fractions or grades, allowing for precise quality control and ensuring consistent product specifications.

2.Scalping and Oversize Removal: In many industries, vibratory separators are used for scalping or removing oversized particles or impurities from the main material stream. This helps to improve downstream processing efficiency and product quality.

3.Solid-Liquid Separation: Vibratory separators equipped with specific screens or meshes can be used for solid-liquid separation. They efficiently remove solid particles or impurities from liquid materials, such as removing debris from wastewater or separating solids from slurries.

Types of vibratory separator

There are several types of vibratory separators available, each designed to suit specific applications and requirements. Here are some common types of vibratory separators:

1. Circular Vibratory Separator: It can remove agglomerates and contaminants from products. It can provide up to 5 levels of classification in one operation to achieve accurate particle size distribution, and the output can range from 100-3300 kilograms per hour.

2. Ultrasonic Vibratory Separator: The added ultrasonic system, which consists of a generator and a probe, applies ultrasonic frequency to the screen. It is designed to make difficult-to-screen powders easy to screen and not easy to block the screen, allowing accurate separation to 20m (#635 mesh).

3. Tumbler Vibratory Separator: simulates the action of manual screening, producing a three-dimensional rolling motion of horizontal and throwing. It is suitable for fine-grained materials within 500 mesh. The screening accuracy is increased by 90-95%, and the output is 5 times that of a circular vibrating screen. -10 times, it is a high-precision, high-output screening equipment. In addition, the swing screen does not vibrate at high speed, so fragile materials and agglomerates will not be destroyed, which improves the quality of the finished product.

4. Vibrating Filter Separator: often used in the liquid filtration industry, it can remove unnecessary particles present in liquids or suspended solids. Of course, it can also be used as powder impurity removal equipment. Its small size can be used in factories or factories with small processing volumes. Small workshop.

Benefits of circular vibratory separator

1. In order to avoid the phenomenon of slurry splashing during the screening of liquid materials, the upper frame of the vibratory separator is heightened, and the inlet is designed with a plus edge.

2. In order to maximize the screening efficiency of materials and prevent them from being discharged before being sieved cleanly, the vibratory separator adopts a single discharge port design, which effectively prolongs the screening time of the materials on the screen surface and increases the screening efficiency.

3. It can be sieved within 500 meshes, the filtration can reach 5 microns, and the output can reach 5 tons/hour.

4. IP54 grade waterproof vibration motor, can work continuously in humid environment, safe and stable operation.

Working principle of vibratory separator

Vibratory separator uses ordinary motor or YZUL vertical vibration motor as the power source. When the rotary vibrating screen is working, the exciter shaft rotates at a high speed, and the eccentric bodies at both ends form a consistent force, and the screen body produces double-rotational vibration under the action of this force. The trajectory of the movement is a three-dimensional curve in space. The projection of this curve on the horizontal plane is a circle, and the projection on the two vertical planes is an ellipse. Adjusting the angle between the two eccentric bodies can change the flow mode of the material on the screen surface to achieve different The screening effect.

Technical parameters of vibratory separator

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Upgrades available

1.Multi-Deck Screens: llows the use of multiple layers of screens on the vibrating screen, allowing for finer particle sorting and grading. The vibratory separator can be installed with 4 layers of screens with different numbers of layers to achieve a 6-stage separation process.

2.Mesh Deblinding Systems: Mesh deblinding systems are designed to prevent the clogging or blinding of the screen mesh, which can occur when fine particles or sticky materials adhere to the surface, reducing the screening efficiency. Deblinding systems use various methods to continuously or intermittently clean the mesh surface during operation, ensuring consistent and effective particle separation. Common deblinding systems include rubber balls, sliders or discs, and ultrasonic systems that help dislodge particles from the mesh openings.

3.Screen Deck Lifting System: A screen deck lifting system enables easy access and maintenance of the screens in a vibratory separator. It allows for quick and convenient screen changes, cleaning, and inspection by lifting the entire deck or individual screen sections. This feature simplifies maintenance procedures and reduces downtime, as operators can easily access the screens for cleaning or replacement without requiring extensive disassembly.

4.Dust Covers: Dust covers are installed on vibrating screens to reduce the spread of dust and particles, keeping the job site clean and operators safe. Dust shields also help collect and control the loss of fine particles.

Application of vibratory separator

Vibratory separators can handle a wide range of materials, including powders, granules, and liquids. They are used in various industries, such as food and beverage, pharmaceuticals, chemicals, and mining, for applications such as grading, scalping, dewatering, and solid-liquid separation.

Here are a few examples of where it can help you:

1.Remove heavy or sticky contamination from liquid chocolate

2.Remove dust and agglomerates from pharmaceutical granules

3.Continuously remove solids from water or other liquid streams in recycling plants

4.Size metal powders accurately into discrete particle size fractions

Related Case Studies

-

Soybean grading

A soybean processing plant uses a vibrating screener to screen and classify raw soybeans. They use a circular vibrating screen equipped with screens of different sizes to separate soybeans into different particle size classes. This helps remove impurities, maintain product quality, and provide consistent feedstock for subsequent processing steps.

-

Flour sifting

A flour manufacturer uses a vibrating sifter to sift and classify flour into fines. They use a rectangular vibrating sifter to separate the flour into coarse, medium and fine flour grades through different levels of sieves. This helps control the particle size and quality of flour and meet the requirements of different product specifications.

-

Feed screening

A livestock company uses a vibrating screen machine to screen and clean feed ingredients. They use circular vibrating screens to separate the feed into components of different particle sizes, removing impurities and particle inhomogeneities. This helps improve the accuracy and uniformity of feed formulations, ensuring nutritional balance and quality control in livestock production.

-

It is suitable for large-scale grain crops and feed processing plants to remove impurities such as dust, sundries, bad grains, and small stones in grains... ...

-

PVC Resin Rotary Vibrator Separator

Gentle screening will not damage any PVC resin structure, and it is not easy to generate static electricity.... ...

-

Used to safely remove contaminants and lumps in powder... ...

-

How much is a PVC resin rotary vibrator separator

The particle size of PVC Resin material is between 60-200 mesh, and its specific gravity is relatively light, and it is prone to static electricity problems...

-

Grain vibro separator to choose vibro sifter

Grain vibro separator is a screening device produced by people to remove impurities contained in grain, or a sieve for seed selection ...

-

What kinds of materials does the powder separator machine have

What kinds of materials does the powder separator machine have? The rotary vibrating screen is a relatively basic model among many ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.