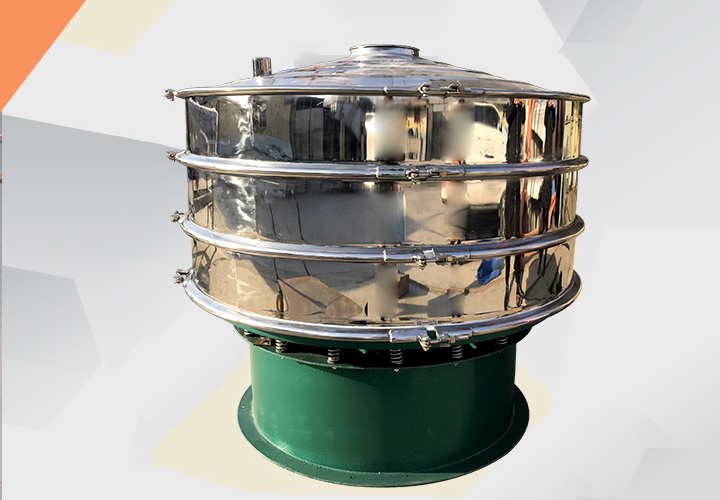

Beans Screener

![[field:title/]](/uploads/211117/1-21111G55115G1.jpg)

Callback

| Mesh size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

According to 1-5 layers of screens, 2-6 different levels of sorting can be completed at the same time.

The machine has been rigorously polished and polished to ensure that the whole machine has no barbs and black spots

Commonly used screen meshes range from 20 meshes to 100 meshes

Introduction of beans screener

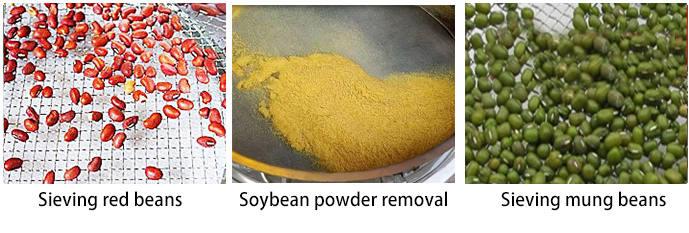

The Beans screener can remove large debris and fine dust such as straw, stones, twine, agglomeration, etc. contained in the beans, and screen out the soybeans that do not meet the requirements to ensure the quality of the finished soybeans. The beans are divided into 2-6 different sizes, which have reached the packaging requirements.

In general, freshly harvested beans need to be divided into three grades. The first layer is used to remove the dust and dried beans contained in the beans; the middle layer is broken, small and unsightly, and used to make bean paste; the bottom layer is small particles, which are crushed into powder and used as additives for other foods.

Application of beans screener

Beans screener can be used to screen different kinds of soy products, that is, soy foods with soybeans as raw materials and other soy products with other miscellaneous beans as raw materials. Soy foods include soy flour, tofu, soy milk, soy milk powder, tofu skin, oil skin, dried tofu, yuba, vegetarian chicken, vegetarian ham, fermented soybean products, soybean protein powder and its products, soybean bars, frozen soybean food, etc. Fermented soy products such as tempeh, fermented bean curd, tempeh, soy milk, etc.

Featured videos

-

Sieving red beans (divide the beans into different sizes)

-

Sieving soybeans (remove impurities in the beans)

Benefits of beans screener

1. According to 1-5 layers of screen, 2-6 different levels of sorting can be completed at the same time.

2. The output per hour is 100-3300 kg, the selectivity is 95%, and the production efficiency is doubled.

3. Use electromechanical automation equipment to replace manual operation, save a lot of labor costs and reduce workshop production expenses.

4. Compared with the original manual operation, the sorting is more accurate through the screen inspection. Improve the efficiency of using beans of various specifications in an all-round way.

Working principle of beans screener

The Beans screener uses a vertical vibration motor as the excitation source. The screen frame is driven by the motor to make a plane, tilt, and vertical three-dimensional motion. After the beans enter the screen surface, the beans of different specifications are discharged from different materials through the three-dimensional motion of the screen frame. The bottom of the screen surface is equipped with cleaning device to solve the problem of blocking in the bean production process. A reasonable increase in the motor excitation force can realize the secondary crushing function of the bean products, simplify the production process and save equipment investment costs.

Technical parameters of beans screener

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases

-

Used for screening, classifying and removing impurities in various powder ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision ...

-

What is the price of sesame vibro sifter?

The price of sesame vibro sifter of Xinxiang Dahan Factory is around $638~$1700 ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.