Gyratory Vibrating Screen

![[field:title/]](/uploads/flink/250110/6-250110142R4319.jpg)

Callback

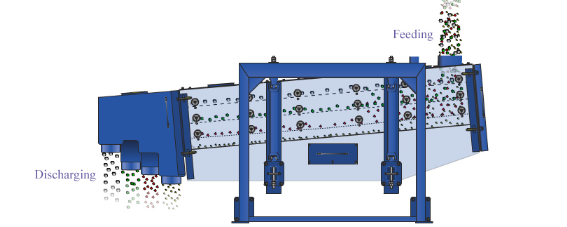

Gyratory vibrating screen is an efficient screening equipment that achieves high-precision screening of materials through a unique screening method.

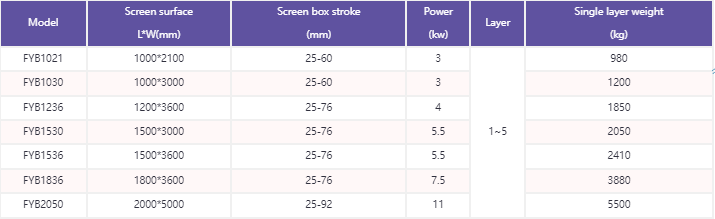

Sieve surface inclination:5-8°

Screen box stroke:25-60mm

Mesh number: ≤350 mesh or ≥0.028mm

Material: 316L stainless steel, 304 stainless steel, carbon steel.

Screen size: 1m-2m*2.1m-5m

Selling points:

1、Accurate to 6-level separation

2、Thehe screening efficiency is as high as 90%-99%

3、Suitable for all fine and ultra-fine powder and granular materials

What is Rotary vibrating screen

Gyratory Vibrating Screen is a device used to screen and grade granular or powdery materials. It combines rotational motion and vibration, and can effectively separate materials according to particle size. It is widely used in chemical, food, medicine, metallurgy and other industries.

How does Rotary vibrating screen work?

After the material enters the screen box of the rotary vibrating screen from the feeding device, the material begins to move on the screen under the joint action of the rotary device and the vibrating device. The rotary motion makes the material move continuously in the circumferential direction, while the vibration makes the material jump and roll in the vertical direction. Smaller material particles can fall into the lower layer through the sieve holes of the screen, and larger particles cannot pass through the sieve holes and will be discharged from another discharge port.

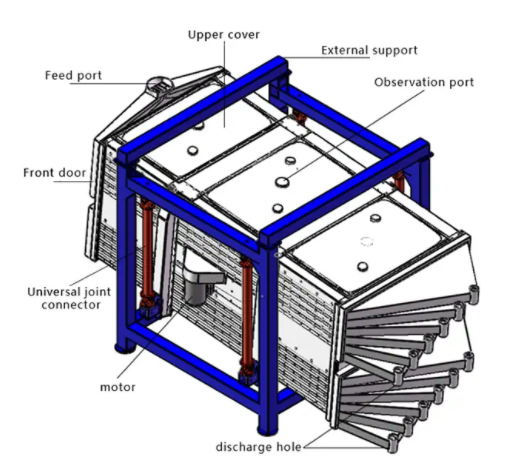

Characteristics of Rotary vibrating screen

1. Efficient screening: particles of different particle sizes can be screened out efficiently.

2. Continuous operation: screening operations can be performed continuously to improve production efficiency.

3. Multi-layer screen: usually with multi-layer screens, multi-level screening can be performed simultaneously.

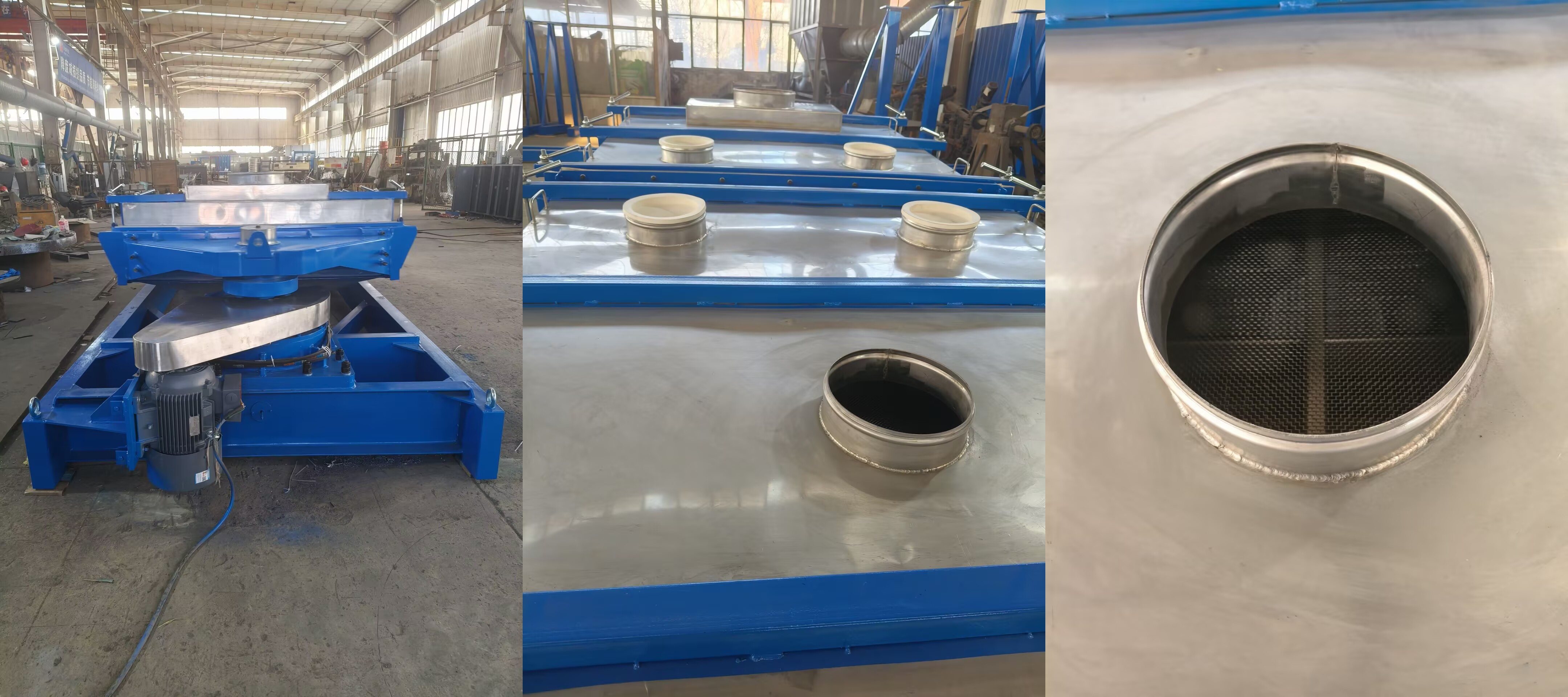

4. Automatic cleaning: The equipment usually has an automatic cleaning function to keep the screen clean and reduce clogging.

What types of Rotary vibrating screens are there?

Gyratory vibrating screen achieves efficient use of the equipment with its unique multi-layer classification design concept. This design usually includes 3 to 5 layers of screens, which can simultaneously complete the classification of 4 to 6 materials of different particle sizes, and the number of screen layers can be flexibly adjusted to meet specific needs.

Single-source gyratory vibrating screen: equipped with one vibration source, suitable for processing materials with larger particle size and low screening accuracy requirements, commonly used in small production lines or laboratory environments.

Dual-source gyratory vibrating screen: equipped with two or more vibrators, which significantly improves the screening efficiency and screen cleaning effect. It can handle a variety of materials including wet materials and sticky materials, and is suitable for occasions with high requirements on screening accuracy and screening capacity.

Specifications of Rotary vibrating screen

What can Rotary vibrating screen be used for

As an efficient screening equipment, the rotary vibrating screen plays an important role in many industries. Mining industry: The rotary vibrating screen is used to screen the ore after coarse, medium and fine crushing to obtain products of different particle sizes.

Building materials industry: Used to screen sand, gravel and aggregates to meet the requirements of concrete and asphalt of different specifications.

Pharmaceutical industry: Used for crushing and screening of Chinese medicinal materials, and particle size control of Western medicine raw materials.

Environmental protection industry: Used for sludge dehydration, solid-liquid separation, etc.

Rotary Vibrating Screen Supplier

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.