Plastic Vibrating Screen

![[field:title/]](/uploads/220727/1-220HG52641317.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Material introduction: Polypropylene is a polymer obtained by addition polymerization of propylene. It is a white waxy material with a transparent and light appearance.

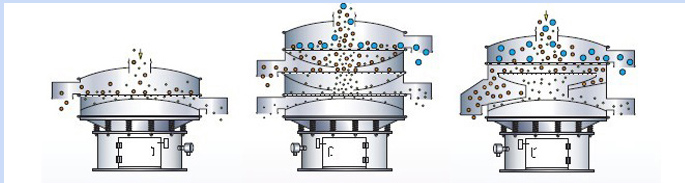

Plastic vibrating screen is made of plastic material after heavy processing. Its main function is to remove impurities, filter and classify, that is to say, the impurities in the material must be processed first (impurities refer to large particles or small particles, etc. meet the requirements), then filter out the impurities in the liquid, and finally divide a pile of materials into N specifications according to the particle size section, and implement classification and utilization.

Advantages of Plastic vibrating screen

Resistant to strong acid and alkali corrosion

Plastic vibrating screen screen meshes are all made of polypropylene material, which solves the solution of screening, impurity removal and filtration of materials with oxidized and corroded steel materials, and ensures that materials will not deteriorate during the screening process.

Single or multi-layer sorting

Screening as fine as 500 mesh (0.028mm), filtering to 5 microns, classified screening, can be configured with 1-5 layers of screens, and can carry out 2-6 grades of sorting or filtration at the same time

Not easy to block the network

The screen cleaning device is used to continuously impact the screen through frequency vibration, so that the material can penetrate the screen smoothly without blocking the screen, and the speed of penetration is fast.

technical parameter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Plastic vibrating screen Purpose of use

Purpose of use: grading, removing liquid, removing impurities.

1. Classification: SLS series three-dimensional vibrating screening filter can classify solid particles into particle groups of equal size. A single series of plastic vibrating sahib can be equipped with 1 to 5 layers of screens, which can accurately and continuously classify 2 to 6 particle segments at the same time; the classification accuracy is over 95%.

2. Liquid removal: This equipment is used in single layer and multi-layer, which can quickly remove the insoluble large particles in all kinds of slurries, quickly realize solid-liquid separation, and the filtering capacity per hour is as high as 20 tons.

3. Impurity removal: It can quickly remove large or small particles with a low percentage content, and the accuracy can reach more than 98%.

Precautions for using Plastic vibrating screen

1. The material must be uniformly fed: the amount of feeding should meet the equipment processing. Too much material feeding at one time will hinder the normal movement of the material on the screen surface, which will not only easily make the screen mesh fatigued and loosen, but also greatly reduce the material handling capacity. Giving a large amount of material at one time will suddenly increase the load of the motor that is running unbalanced, causing damage to the motor and reducing the life of the motor. If the feeding amount cannot reach the processing capacity of the equipment, it will waste energy and reduce the output.

2. For the feeding method with strong impact force, a buffer hopper must be installed, and the material directly impacts the mesh surface, which not only consumes the exciting force generated by the vibration source, but also easily causes damage to the mesh surface and screen fatigue, which affects the output and screening. .Quality of filtration.

3. If the screening material is corrosive, please clean it up in time after use.

4. Please check whether the working net becomes loose, and make the net taut again.

-

Corrosion Resistant Vibro Sifter

The screen machine is made of polypropylene propylene pp material

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.