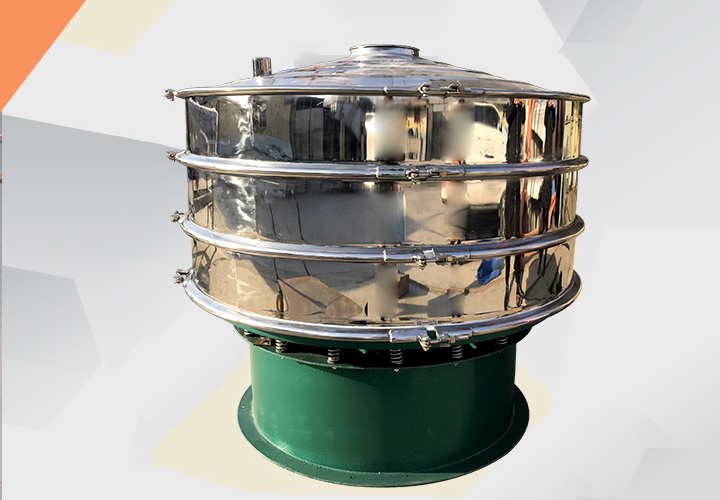

Sand Screening Machine

![[field:title/]](/uploads/211118/1-21111P95640638.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

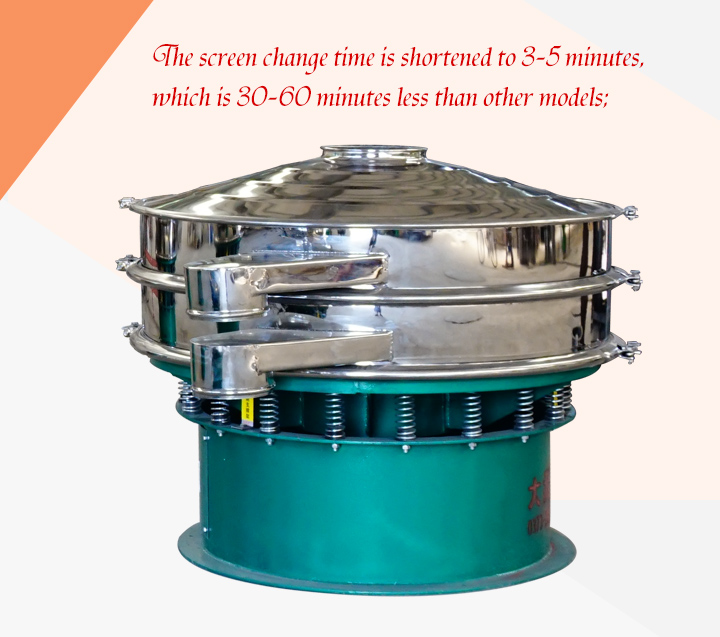

Which is 30-60 minutes less than other models.

The mesh is not deformed, the screen has a long service life and high efficiency.

A variety of specially designed screen cleaning devices minimize the chance of blocking the screen.

Introduction of sand screening machine

The rough-processed sand with the grades of 1-0.5mm and 0.5-0.1mm can be vibrated with a vibrating mill/vibrating rod mill. After grinding, it can be sieved with a screening machine to prepare a fine powder of about 100-300 mesh. Sand screening machine can screen and process the quartz sand output up to 1-5T per hour, and can install 1-5 layers of screens to remove impurities of 2-6 different specifications of quartz sand.

Benefits of sand screening machine

1. The widest screening range: suitable for screening and separation of various particles, powders and slurries. The sieving particle size can reach 500-600 mesh, and the filter particle size can reach 5 microns.

2. No screen blocking: A variety of specially designed screen cleaning devices minimize the chance of blocking the screen.

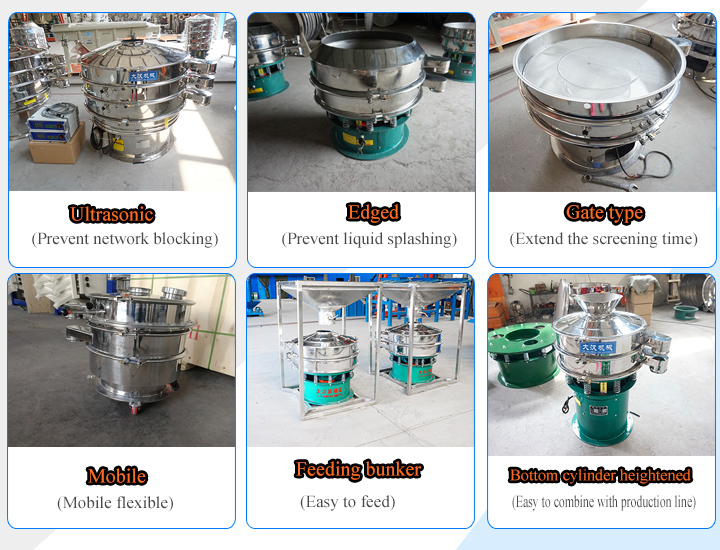

3. Single-layer and multi-layer separation: Single XC vibrating screen can choose 1-5 layers of screening, and can carry out 2-6 grades of sorting. Single-layer filtration can meet the requirements at one time.

4. Convenient screen change: XC vibrating screen has a variety of grid structures according to different needs; the screen change time is shortened to 3-5 minutes, which is 30-60 minutes less than other models;

5. The mesh is not deformed, the screen has a long service life and high efficiency.

Working principle of sand screening machine

Sand screening machine uses the YZUL vertical vibration motor as the excitation source, and uses the eccentric weights at the upper and lower ends of the vibration motor to convert the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, and transmits it to the separation machine screen surface; cocoa passes The inlet enters the equipment. According to different screening requirements, the cocoa passes through the sieve layer of the screen. In this process, the cleaning device under the screen-the bouncing ball constantly hits the screen , so that the materials on the screen can be smooth. Through the screen screening, and effectively solve the problem of material blockage, the screened material and the screened material are discharged from different outlets, so as to achieve the purpose of screening and removing impurities or filtering and grading.

Technical parameters of sand screening machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Application of sand screening machine

Sand screening machine is used for the screening and grading of quartz sand. Because the particle size of quartz sand is different, the common specifications are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm , 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-120 mesh, the following is the application of different quartz sand.

-

Used for screening, classifying and removing impurities in various powder ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.