Sea Salt Sieve

![[field:title/]](/uploads/211129/1-211129103T2132.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high.

The parts in contact with the materials must be made of SUS304 stainless steel

It can not only classify the sea salt in multiple layers

Introduction of sea salt sieve

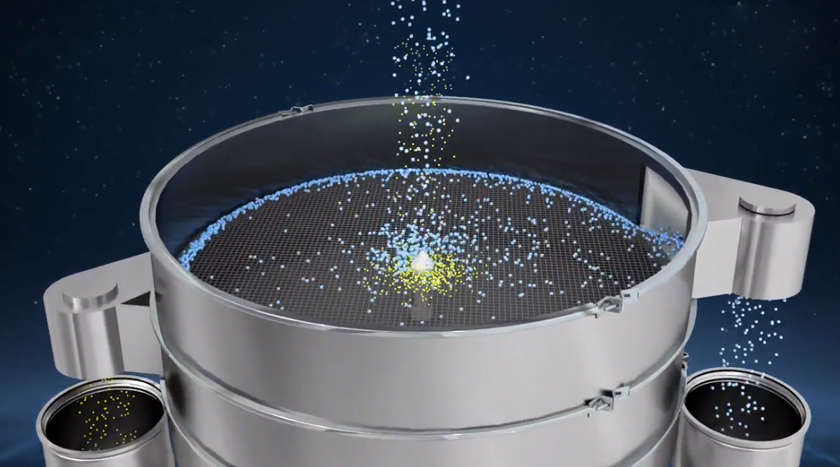

Sea salt sieve dehydrates and classifies raw salt with a certain frequency and amplitude. It is more mature in sea salt production areas. It has obvious effect on removing powder salt and solid impurities with small particle size, reducing insolubles in industrial brine and improving the quality of industrial salt. Because sea salt is corrosive, the sea salt sieve is made of 304 stainless steel, which can be used for a longer time and also has a protective effect on the material.

Application of sea salt sieve

Refined table salt is the salt that removes insoluble impurities and increases the sodium chloride content after raw salt is processed. There are 4 processing methods:

1. Crushing washing method: the raw salt is pulverized with a pulverizer, and then sieved and classified by a vibrating screen (rotary vibrating screen), then transported to the salt washer and washed with saturated brine, and the two are mixed into a salt slurry state and discharged After the impurities, they are dewatered by a centrifuge, and become the so-called washing salt after being filtered and dried;

2. Pot boiling method: the saturated brine is first rinsed to filter the impurities such as sediment, sodium hydroxide is added to remove magnesium and calcium ions, and then sent to the boiling pot for steaming into salt, and then dehydrated, dried, crushed, sieved, etc. The procedure is "tortion salt" or "re-salt". The purpose of sieving here is to sieve loose, remove large particles, clumps, and agglomerated salt particles to ensure that the finished salt particles are uniform and do not affect the quality of use;

3. Vacuum tank evaporation method: It is a method of making pure bittern under low pressure and high temperature.

4. Electrolysis method: the method is to make concentrated halogen by electrolysis method, and then use the vacuum evaporation tank to heat the salt.

The last two salt making methods also need to use sea salt sieve to remove large particles, clumps, and agglomerated salt particles to ensure that the finished salt particles are uniform.

Working principle of sea salt sieve

Sea salt sieve uses YZUL vertical vibration motor as the excitation source. The eccentric weight at the upper and lower ends of the vibration motor converts the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, which is transmitted to the screen surface , and the material passes through the feed After entering the equipment, according to the screening requirements of the material, the material passes through the 1-5 layers of screens with different meshes. In this process, the cleaning device (bouncing ball) located under the screens of each layer will be Constantly hitting the screen allows the material on the screen to pass through the screen smoothly, and effectively solves the problem of material blockage. The materials of different meshes are discharged on each layer after passing through the screens of the corresponding meshes of each layer. It is discharged from the mouth, and finally achieves the purpose of screening and removing impurities or filtering and grading.

Featured videos

-

Remove impurities in sea salt

-

Sea salt classification production line

Benefits of sea salt sieve

1. The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high.

2. The parts in contact with the materials must be made of SUS304 stainless steel, and the sealing device and the cleaning device must use silicone rings and silicone balls that meet the requirements of the food industry, clean and sanitary, and will not pollute the materials.

3. It can not only classify the sea salt in multiple layers, but also filter the silt in the brine in a single layer.

4. It can carry out 2-6 levels of screening and classification at the same time, automatically discharge impurities and coarse materials, and the processing capacity can reach 3300kg/h.

Technical parameters of sea salt sieve

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases of sea salt sieve

| Materials | Mesh | Capacity (kg/h) |

Model |

| coarse salt | 5mm | 400-500 | DH-1200-2S |

| cooking salt | 18 mesh | 200 | DH-800-1S |

| salt | 30 mesh | 5000 | DH-1500-1S |

| hydrochloric acid | 100 mesh | 300 | DH-1200-1S |

-

Can be used for grain, powder, granule and liquid. ...

-

One of precised powder sieve,suitable for any particle...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.