Sifter Industrial

![[field:title/]](/uploads/211111/1-2111111F11X26.jpg)

Callback

| Mesh size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

Accurately grades up to 6 particle sizes

Special screen cleaning system, not easy to block

Totally enclosed system to reduce dust contamination

Introduction of sifter industrial

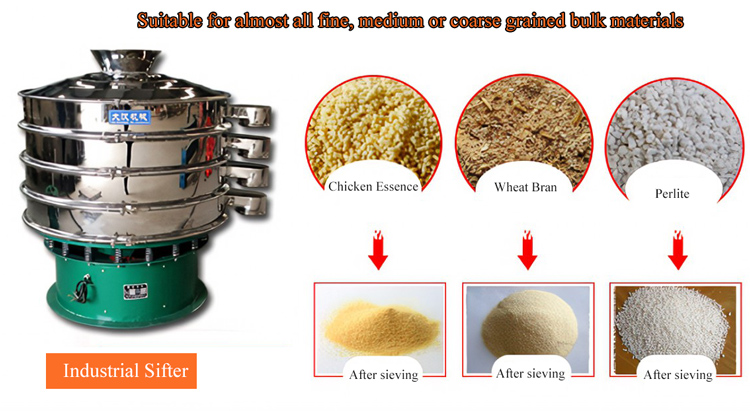

Sifter industrial is specially designed for bulk material classification, safety and inspection screening, and is suitable for almost all bulk materials with fine, medium or coarse granularity. They are also very suitable for wet screening applications. It is very suitable for factories and factories that need to handle a large number of products. The sifter industrial adopts a fully enclosed system to reduce dust problems in the air and protect the surrounding environment.

How does it works?

The material enters the sifter industrial through the inlet. According to different material screening requirements, the material passes through the sieve layer of the screen. In this process, the net cleaning device under the screen-the bouncing ball continuously hits the screen to make the screen Layer materials can be screened through the mesh smoothly, and effectively solve the problem of material blockage. The screened material and the screened material are discharged from different outlets, so as to achieve the purpose of screening and removing impurities or filtering and grading. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Featured videos

-

Sifter industrial for sieving Coke

-

Industrial sifter for flour

Benefits of our sifter industrial

1. It is suitable for dry and wet screening and classification of powder, granular, fibrous materials or slurry in various industrial fields, and has a wide range of applications

2. The mesh is relatively fine, which can screen materials well but is not easy to block, and will not cause the powder to fly. It can be sieved to 500 mesh or 0.028mm.

3. Adopt a closed working environment to ensure that materials are not interfered by external factors during screening and reduce pollution.

4. Automatically process the impurities and coarse materials after screening, saving labor, after screening, you can enter the next round of screening work by yourself, and continue to work.

Technical parameters of sifter industrial

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Application of sifter industrial

| Application of Sifter industrial in food and medicine industry | Application of Sifter industrial in metal, metallurgy and mining | ||||||||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT | Graphite | 1.2 | 16/40/80 | DH-1000-3S | Dry | 1400㎏ |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ | Lead powder | 11.34 | 10/80 | DH-1000-2S | Dry | 1000㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT | Iron powder | 3 | 400 | DH-800-1S | Dry | 230㎏ |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ | Emery | 4 | 60 | DH-1000-1S | Dry | 300㎏ |

| Medicine powder | 0.8 | 80 | DH-800-1S | Dry | 550㎏ | Aluminum powder | 0.9/1.2 | 80/120 | DH-800-2S | Dry | 350㎏ |

| Application of Sifter industrial in related industries of kiln industry | Application of Sifter industrial in pollution treatment and other industries | ||||||||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Spray soil particles | 2 | 10 | DH-1000-1S | Dry | 18000㎏ | Waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000IT |

| Mica | 0.8 | 200 | DH-800-1S | Dry | 110㎏ | Dyeing and steaming wastewater | 1 | 150 | DH-1000-1S | Wet | 22000IT |

| Feldspar | 2.5 | 60/100 | DH-1000-2S | Dry | 350㎏ | Waste oil | 0.9 | 100 | DH-1000-1S | Wet | 3800IT |

| Quicklime | 2.5 | 100 | DH-1000-1S | Dry | 480㎏ | ||||||

Sifter industrial can be used in any sieving and filtering industries for powder, granules and liquids. Widely used in chemicals, pharmaceutical powders, liquids, coatings, pigments, cosmetics, oils, resins, ceramic slurries, clay slurries, quicklime, refractory powders, metallurgical powders, electromagnetic powders, grinding powders, fruit juices, beverages, sugar, salt, monosodium glutamate , Seasoning, milk powder, starch, flour, rice flour, carbon powder, graphite powder, manganese powder, lithium carbonate, cosolvent, fire extinguishing agent, as well as screening and filtration in the process of sewage and wastewater treatment in the environmental protection industry.

Related cases

-

Used for screening, classifying and removing impurities in various powder, granular and slurry.. ...

-

One of precised powder sieve,suitable for any particle, powder and mucus material within a certain range.....

-

Flour Sifter Industrial for Sieving Flour

The purpose of flour sifting is mainly to remove impurities and sieve loose, so for different purposes...

-

Types of rotary Industrial sieving machine

Industrial sieving machine is a high-precision screening machine, whether the material is dry or wet, 0-400 ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.