Ultrasonic Vibro Sifter

![[field:title/]](/uploads/211113/1-211113140205222.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Sieving fine to 500 mesh or 0.028mm

Can be used with single-layer and multi-layer screens

Can control the time that the material stays on the mesh surface

Introduction of ultrasonic vibro sifter

Ultrasonic vibro sifter is a set of low-amplitude, high-frequency ultrasonic system installed on the traditional vibro sifter grid, so that the ultra-fine powder receives huge ultrasonic acceleration during screening and filtration, which improves the screening efficiency and the processing capacity. And it can prevent materials from blocking the net. Ultrasonic vibro sifter always keeps the material in suspension when working, thereby inhibiting the blocking factors such as adhesion, friction, flat drop, wedging, etc., and solves the problem of strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, etc. The screening problem of materials has improved the screening performance of ultra-fine subdivisions, so it has a wide range of applications in the chemical, food, construction, and pharmaceutical industries.

Benefits of ultrasonic vibro sifter

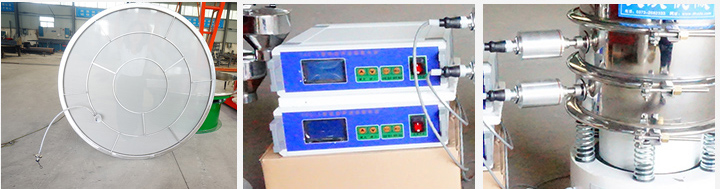

1. The output waveband of the digital control power supply is transmitted to the surface of the screen 360,000 times per minute through the transducer.

2. With self-cleaning function, there is no mesh blockage when screening >500 mesh.

3. It can be used in single layer or multiple layers, and a set of intelligent ultrasonic generator uses three transducers at the same time;

4. It has a better effect on materials that are difficult to screen, such as strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, etc.;

5. Compared with ordinary vibro sifter, the screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

Working principle of ultrasonic vibro sifter

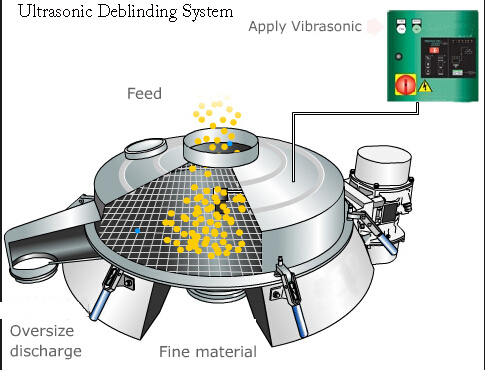

Ultrasonic vibro sifter converts 220V, 50Hz or 110V, 60Hz electric energy into 18KHz high-frequency electric energy, and inputs the ultrasonic transducer to turn it into 18KHz mechanical vibration. When the material is screened, it is not only subjected to the force of the three-dimensional rotating vibrating screen, so that The force of the three-dimensional movement of the material up and down, horizontal and inclined on the screen surface is also affected by the high frequency and low amplitude force exerted on the screen surface by the ultrasonic system, so as to achieve the purpose of screening and cleaning.

Structure of ultrasonic vibro sifter

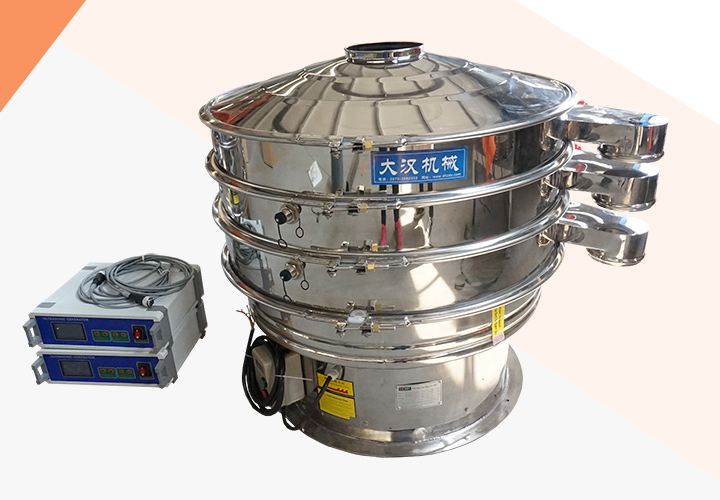

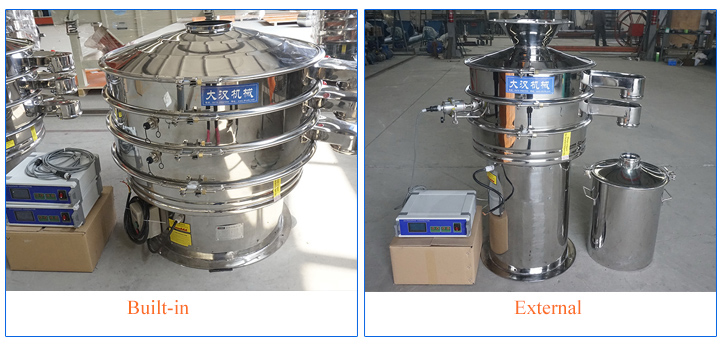

Ultrasonic vibro sifter is composed of a base, a vibration motor, a screen frame, and an ultrasonic screening system. Its internal structure refers to the internal structure of the screen frame. The inside of the screen frame is composed of: screen frame, screen mesh, and ultrasonic transducer.

Technical parameters of ultrasonic vibro sifter

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW |

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW |

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW |

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW |

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW |

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW |

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |

Application of ultrasonic vibro sifter

Ultrasonic vibro sifter can be applied to the screening and classification of ultra-fine materials up to 600 mesh, such as: silicon carbide, electromagnetic powder, tungsten powder, cobalt powder, nickel powder, quartz powder, lithium battery cathode material, anode material, laser powder, carbon powder , Powder coating, alloy powder, molybdenum powder, stainless steel powder, malt powder, spore powder, etc.

-

Ultra-fine powder with high fineness, light specific gravity

-

Suitable for impurity removal and filtration of 200-600 mesh ultra-fine powder

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.