Vibratory Sieve

![[field:title/]](/uploads/211112/1-211112143J1G5.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Sieving fine to 500 mesh (28 mm), filtering up to 5 mm

Can carry out 2-6 levels of sorting or filtering at the same time

Automatic discharge of materials, no stock in the machine

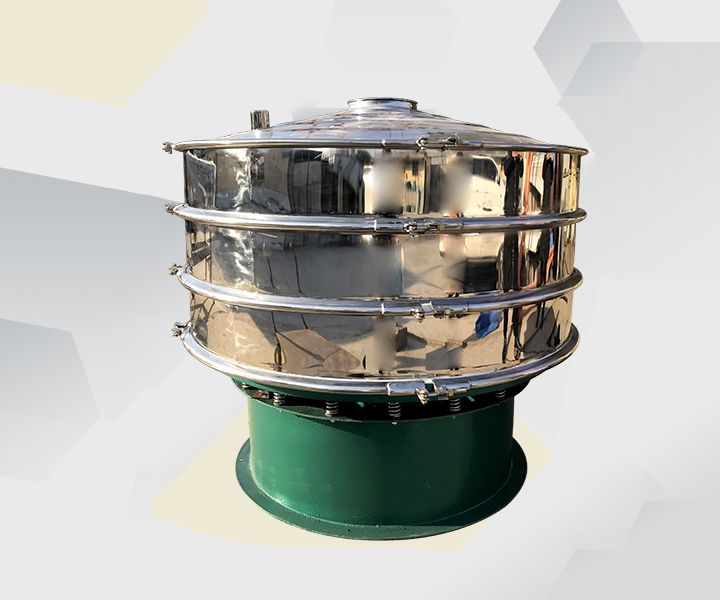

Introduction of vibratory sieve

Vibratory sieve is mainly used in the filtration and sieving of raw materials in the industry. The powder particles are screened by rotary vibrating sieve from the particle size. They are customarily divided into five grades: coarse powder, medium powder, fine powder, fine powder and superfine powder.

Vibratory sieve material can be divided into SUS304 stainless steel, Q235A carbon steel, PP plastic anti-corrosion design and production of three materials, users can choose the material and model of the screen according to their own material characteristics and industrial requirements.

Benefits of vibratory sieve

1. Wide range of screening materials, any powdery or granular materials can be screened.

2. The sieving is fine to 500 mesh or 0.028mm, and the filtering can reach 5 microns.

3. Equipped with a screen cleaning device, which can reduce the blocking of the material during the screening process, and greatly improve the screening output and screening efficiency of the screen.

4. Layers 1-5 can be used at the same time according to different needs of customers. Various models such as carbon steel, 304 stainless steel and plastic materials are complete, and they can also be customized according to your needs.

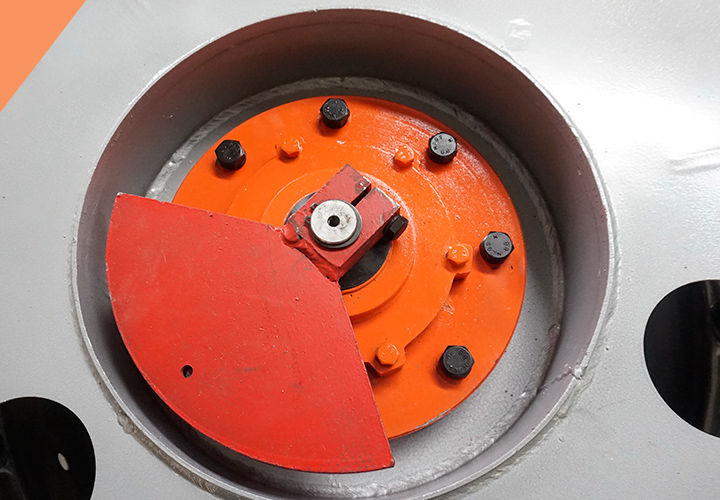

Working principle of vibratory sieve

Vibratory sieve uses YZUL vertical vibration motor as the excitation source. The eccentric weight on the upper and lower ends of the vibration motor converts the rotational motion into horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; the material passes through The feed inlet enters the equipment. According to different material screening requirements, the material passes through 1-5 layers of sieving with different mesh metal woven screens. In this process, a cleaning device is located under the screens of each layer. (Bouncing ball) Continuously hitting the screen through frequency vibration, so that the materials on the screen can be smoothly screened through the screen, and effectively solve the problem of material blockage. After the materials of different meshes pass through the screens of the corresponding meshes of each layer It is discharged at the discharge port of each layer, and finally achie ves the purpose of screening and removing impurities or filtering and grading.

Structure of vibratory sieve

Vibratory sieve is mainly composed of feed port, dust cover, discharge port, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, machine base and other parts.

Dust cover: prevent materials from spreading out, and can also protect external dust from entering, thereby contaminating the screening materials.

Beam ring: used to fix the screen frame in the middle of the screen body.

Upper weight and lower weight: Changing the phase angle of the upper and lower weights of the vibration motor can change the movement trajectory and residence time of the material on the screen.

Spring: vibration damping and sound insulation.

Base: Support the entire vibrating screen to keep its work stable.

Technical parameters of vibratory sieve

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of vibratory sieve

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, dairy products, food additives, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid, Chinese and western medicine granule pills, pellets, industrial medicine granules, etc.

Chemical industry: resins, coatings, industrial medicines, cosmetics, paints.

Metallurgical industry: aluminum powder, lead powder, copper powder, electrode powder, manganese dioxide, electrolytic copper powder, etc.

Other industries: gypsum, talc, sand, paper, activated carbon, additives, etc.

-

Vibratory Sifter manufacturer-dahan provides various models of vibratory sifters to increase your pro ...

-

Used for screening, classifying and removing impurities in various powder ...

-

Any powder, granules and slurries can be screened efficiently....

-

Different types of powder sieve machine

The powder sieve machine can be used for the screening of various powder materials. ...

-

Powder Sieving Machine for epoxy

Resin refers to a general term for a class of polymers containing two or more epoxy groups in...

-

How to improve the working efficiency of the vibrating screening machine?

The working efficiency of the vibrating screening machine is certain, but in special cases ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.