What exactly is the Teflon Vibrating Screen?

"Our materials can't be in contact with other materials" "Our materials can't rub against the screen frame to produce fine powder during production", these are what some users mentioned when they consulted vibrating screening equipment. In response to these requirements, DAHAN has designed and produced the teflon Vibrating Screen.

Teflon's scientific name is polytetrafluoroethylene, which is generally referred to as "non-stick coating" or "easy-to-clean material". This material has the characteristics of acid and alkali resistance and resistance to various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its friction coefficient is extremely low, so it can be used for lubrication, and it has also become an ideal coating for easy cleaning of the inner layer of water pipes. Due to its characteristics, in the production process of the vibrating screen, in order to avoid the secondary pollution of the user's materials, the internal injection of Teflon will be used.

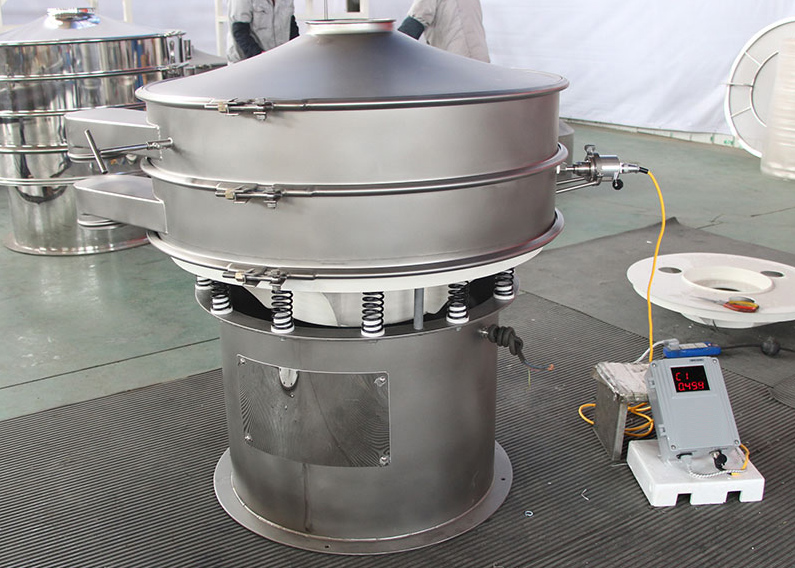

The main components of Teflon Vibrating Screen are: bottom barrel, vertical vibration motor, vibration damping spring, screen frame, screen mesh, ultrasonic cleaning device, and dust cover. The equipment is composed of ultrasonic resonance power supply, oscillator and resonance ring. The high-frequency electrical oscillations generated by the ultrasonic resonant power supply are converted into longitudinal oscillation waves in the form of high-frequency sinusoids by the oscillator. These oscillation waves are transmitted to the resonant ring to resonate the resonant ring, and then the resonant ring transmits the vibration evenly to the screen surface. The materials on the screen are subjected to low-frequency three-dimensional vibration, and ultrasonic vibration is superimposed, which can not only prevent the mesh from clogging, but also improve the screening output and quality.

What Teflon Vibrating Screen can achieve

1. Isolate the contact between the material and the equipment material, and effectively avoid the secondary pollution of the material;

2. Effectively improve the screening accuracy, the screening accuracy can reach more than 95%;

3. The output is 1-5 times that of ordinary vibrating screen;

4. Effectively solve the screening problems such as blocking, sticking, troupe, adsorption, and static electricity caused by special materials in the screening process;

5. It is easy to change the net, simple to operate, easy to move, and has a long service life.

-

Non-stick properties or anti-stick properties, easy to clean

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.