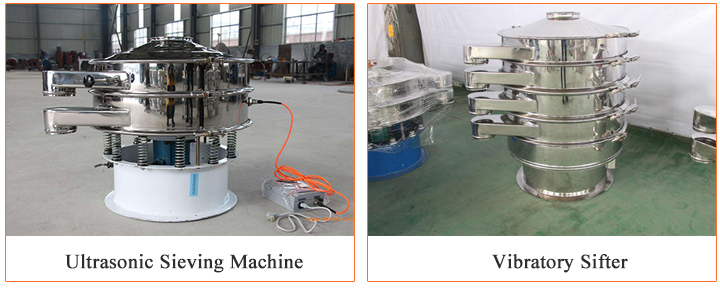

What is the difference between ultrasonic sieving machine and vibratory sifter

Many people have the same questions about Ultrasonic Sieving Machine and Vibratory Sifter. What is the difference between them? Are they the same function? The Ultrasonic Sieving Machine and the Vibratory Sifter belong to the same screening equipment. The Ultrasonic Sieving Machine is a derivative of the Vibratory Sifter, but the Ultrasonic Sieving Machine adds an ultrasonic system on the basis of the original Vibratory Sifter. Combining your questions, focus on analyzing the difference between Ultrasonic Sieving Machine and Vibratory Sifter!

The structure difference between Ultrasonic Sieving Machine and Vibratory Sifter

The main function of the Ultrasonic Sieving Machine is to screen the material. On the basis of the traditional vibrating screen, a low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) is introduced on the screen to improve the screening performance of the ultra-fine subdivided body. The sub-precision and effect are greatly improved, and it is especially suitable for users with high value-added fine splits.

Features of Ultrasonic Sieving Machine

High technical content

The Ultrasonic Sieving Machine organically combines the ultrasonic controller and the vibrating screen, and superimposes a high-frequency and low-amplitude ultrasonic vibration wave on the screen layer, which can keep the material on the screen surface in suspension at all times and ensure that the material is finely sieved It is clean, does not block the network, and does not leak materials.

Good screening effect

When ordinary vibrating screens sieving materials, there will be materials sticking to the screen or screen wall. Ultrasonic Vibratory Sifters solve this screening problem. The strong adsorption, easy agglomeration, high static electricity, high precision, In the case of high density and light specific gravity, the ultrasonic vibrating screen can be solved.

Body material uses stainless steel

Ultrasonic is suitable for light and fine screening industries, especially for food and pharmaceutical industries. Therefore, its material is generally made of stainless steel, with a neat and clean appearance, smooth and non-marking, not easy to deform, wear-resistant and corrosion-resistant, and has a long overall service life.

Easy maintenance

There are no dead corners in the ultrasonic part, it is easier to clean and disinfect thoroughly, easy to install and disassemble, good overall performance, strong sealing performance during operation, powder is not easy to fly, liquid will not leak, single layer, multi-layer use, up to five layers.

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.