Wheat Flour Sifter

Callback

| Screen size: | 2-500 mesh ((0.5-0.025mm) |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

SUS304 stainless steel, fully enclosed structure, clean and sanitary, no dust

The screen surface is equipped with a cleaning device, and the screen hole is not easy to be blocked

High screening accuracy, mostly above 90%

Introduction of wheat flour sifter

Wheat flour sifter, also called wheat flour sieving machine, is used for fine safety screening and inspection screening of flour in food factories and flour production lines. It is mainly used to remove agglomerates, foreign matter and contaminants in flour, and improve the product quality of materials before packaging. .

Why use wheat flour sifter

It can be used for cakes, pastry processing, other edible product ingredients, etc.

The flour rotary vibrating screen is made of 304/316 stainless steel that is not easy to rust, and uses the silicone sealing ring and net-cleaning pinball used in the food industry.

Flour is sieved with different mesh numbers according to different uses, and the final processing amount is also different.

| flour state | mesh | Handling capacity (kg/hour) |

| dry | 20 mesh (0.8mm) | 2000 |

| 30 mesh (0.55mm), 45 mesh (0.18mm) | 1500 | |

| 80 mesh (0.18mm) | 1200 |

Common types of wheat flour sifter

-

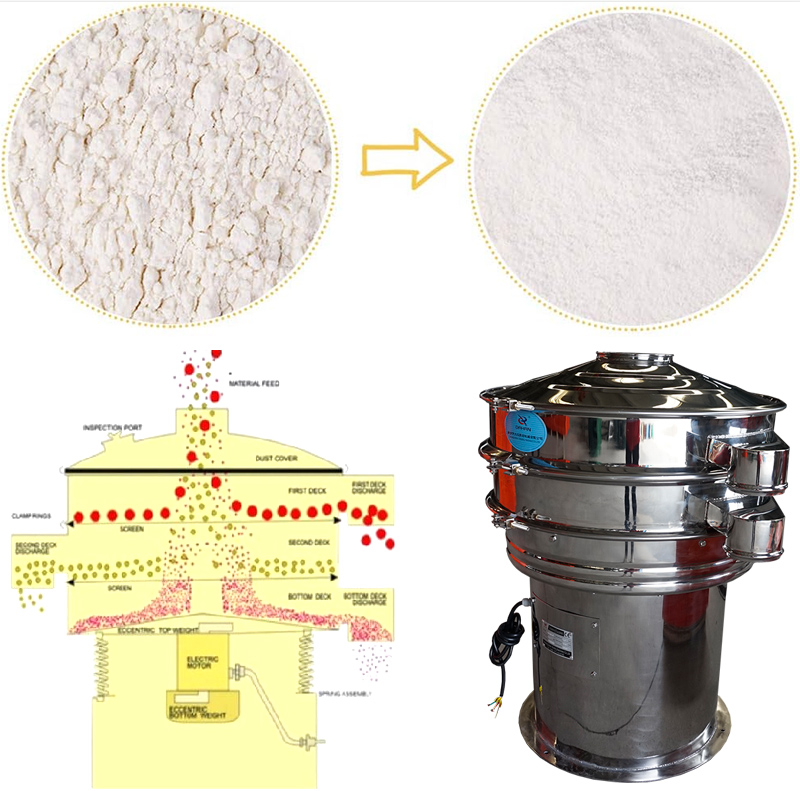

vibro sifter

While removing impurities such as agglomerates and lint from the powder, it meets the primary requirements for food safety. At the same time, wheat flour is classified into different finenesses by increasing the number of screen layers.

-

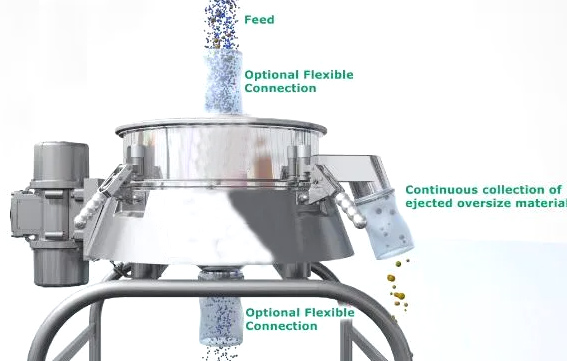

Direct discharge sifter

It is mainly used to remove agglomerates, foreign matter and contaminants from wheat flour. Usually the impurity content is about 5%, so it is very suitable for screening wheat flour powder in large quantities.

-

Airflow screening machine

By utilizing the combined action of airflow and screens, impurities in wheat flour are separated and agglomerates in wheat flour can also be broken. The mesh size is 80-500 mesh, and the output is 5-10 times or higher than that of the vibrating screen.

According to different usage scenarios, the flour rotary vibrating screen has two purposes: filtration and impurity removal and uniform grading:

1. Filtration and impurity removal: Use a single-layer flour rotary vibrating sieve to filter and remove impurities such as wheat, agglomeration, and thread in the flour to meet the primary requirements of food safety;

2. Uniform grading: By increasing the number of sieve layers, the flour is sieved with different finenesses to meet the needs of different grades of flour for different purposes.

Featured videos

-

Wheat starch removal

-

Wheat starch grading

Benefits of wheat flour sifter

1. The sieving is fine to 500 mesh or 0.028mm, the wheat flour has high fineness and precision, and the taste is good.

2. It is made of stainless steel and polished inside and outside, which is clean and hygienic, not easy to rust, and not easy to contaminate flour.

3. Built-in special silica gel ball cleaning device for food industry, the screen is not easy to be blocked, and the screening efficiency is improved.

4. Fully sealed structure can prevent the pollution of the environment caused by the overflow of flour.

5. 1-5 layers of screens can sort out 2-6 different grades of flour at the same time.

6. It can be operated continuously, and the materials can be discharged automatically in a 360-degree direction.

Technical parameters of wheat flour sifter

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases of wheat flour sifter

| Material | Proportion | Mesh | Processing method | Capacity (kg/hr IT/hr) |

Model |

| Wheat flour | 1 | 250 | Wet | 3200 IT | DH-1200-1S | Flour | 0.6 | 24 | Dry | 1500㎏ | DH-1000-1S |

| Rice flour | 0.5 0.8 | 100 | 300 ㎏ | DH-1000-1S | |

| Pollen | 0.4 | 12 | 100㎏ | DH-1500-1S | |

| Skimmed milk powder | 0.57-0.7 | 24 | 3000㎏ | DH-1200-1S | |

| Whole milk powder | 0.57-0.8 | 12 | 1600㎏ | DH-1000-1S | |

| Sugar powder | 0.5-0.8 | 100 | 200㎏ | DH-800-1S |

Application of wheat flour sifter

Wheat flour sifter is often used in the following situations:

1. Wheat starch production: In the production process of wheat starch, wheat flour sifter is often used to screen and classify wheat starch. It sorts wheat starch into different particle size classes, ensuring product quality and consistency.

2. Food processing industry: Wheat starch is one of the commonly used raw materials in many food processing processes. Wheat flour sifter can be used to screen wheat starch to remove impurities and particle clumps to ensure that the wheat starch used in food processing is of good quality.

3. Baking industry: Wheat starch is an important ingredient in many baked goods, such as bread, cakes and biscuits. The wheat flour sifter can be used to sieve wheat starch, remove clumps and impurities, and ensure the fineness and uniformity of the flour for better baking results.

How to choose wheat flour sifter

When choosing a wheat flour sifter, consider the following factors to ensure you select the right one for your needs:

1.Size and capacity: Consider the volume of flour you typically work with. Choose a sifter that can accommodate the amount of flour you commonly use in your recipes. If you often work with large quantities, opt for a larger capacity sifter.

2.Construction and durability: Look for a sifter made of high-quality materials, such as stainless steel or sturdy plastic, that can withstand frequent use and last over time.

3.Mesh or screen quality: Check the quality of the mesh or screen used in the sifter. It should be fine enough to effectively sift the wheat flour and remove any lumps or impurities.

4.Additional features: Some sifters come with extra features like multiple mesh sizes or interchangeable screens, allowing you to sift flour to different fineness levels.

-

A fine powder screening equipment. Any powder, granule and slurry can be sieved ...

-

Screen the coarse particles and impurities in the flour ...

-

How much is a wheat flour sifter

Flour is a food material and generally requires high sanitary conditions. Therefore, Dahan recommends ...

-

How is the flour sifter used in the flour production process?

The processing accuracy of flour is mainly measured by the bran star content of flour. The whiter ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.