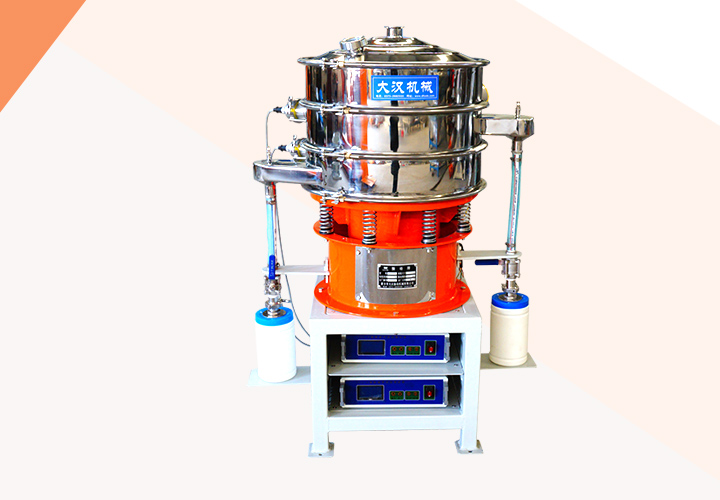

3D Printing Powders Vibrating Sieve

![[field:title/]](/uploads/220623/1-22062314264TN.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Decompose adhering substances and reduce sieves;

Yield can be increased by 0.5-10 times

The 3D printing powders vibrating sieve is to provide an automatic frequency modulation 3D printing metal powder vibrating sieve powder machine, the automatic frequency modulation 3D printing powders vibrating sieve can sieve the metal powder, and finally obtain the metal powder of qualified precision for 3D printing.

In order to achieve the above object, the present invention provides an automatic frequency modulation 3D printing metal powder vibrating sieve machine, the automatic frequency modulation 3D printing powders vibrating sieve includes sequentially from top to bottom: a positioning frame, a motor seat, an elastic mechanism and a base; wherein , a plurality of sieves are positioned above the motor base in the positioning frame, the diameter of the sieve holes of the plurality of sieves gradually decreases from top to bottom, and the bottom surface of the sieve located at the bottom layer is set to be closed, A cover body is arranged on the sieve located on the topmost layer, a vertical motor is installed below the motor base, and an eccentric wheel is arranged on the shaft body of the vertical motor.

Preferably, the base comprises a base plate, a cylinder is fixedly connected to the base plate, the upper end of the cylinder is fixedly sleeved with a lower ring, the lower end of the motor base is fixedly sleeved with an upper ring, and the elastic A mechanism is installed between the upper and lower rings.

3D printing powders vibrating sieve principle

According to the above technical solution, in the present invention, a plurality of sieves are positioned above the motor base in the positioning frame, the diameters of the sieve holes of the sieves gradually decrease from top to bottom, and the sieve located at the bottom layer The bottom surface of the sieve is closed, the screen on the topmost layer is provided with a cover body, a vertical motor is installed below the motor base, and an eccentric wheel is arranged on the shaft body of the vertical motor. When in use, the operation of the vertical motor drives the eccentric wheel to rotate, and then with the cooperation of the single-sex mechanism, multiple sieves are swayed, and then the powder is sifted, and the metal powder of multiple specifications is obtained through the sieves of different specifications, and finally the remaining metal The powder falls into the bottom sieve with no sieve holes for recovery. 0015] Other features and advantages of the present invention will be described in detail in the detailed description that follows.

3D printing powders vibrating sieve parameters

| Model | DH-600 | DH-800 | DH-1000 | DH-1200 | DH-1500 | DH-1800 | DH-2000 |

|

Diameter mm |

Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

|

Screen area m |

0.24 | 0.45 | 0.67 | 1.0 | 1.6 | 2.43 | 3.01 |

|

Screen size (mesh) |

2-500 | ||||||

|

Feed particle size mm |

<Φ10 | <Φ15 | <Φ20 | <Φ30 | |||

|

Vibration times rpm |

1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

|

Effective sieve surface straight mm |

Φ560 | Φ760 | Φ930 | Φ1130 | Φ1430 | Φ1760 | Φ1960 |

| layers | 1-5 | ||||||

|

power Kw |

0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 |

3D printing powders vibrating sieve video

Applications of 3D Printing Powders Vibrating Sieve

3D printing powders vibrating sieve can refine and screen out impurities commonly found in 3D printing materials to improve purity.

Different applications and 3-D machines use various raw materials. Some of the most common include:

-

It can sieve 1-5 layers of screens, and can carry out 2-6 grades of sorting or filtering at the same time.

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.