Influence of 3D printing powder feeding speed on 3D printing powders vibrating sieve

3D printing powders vibrating sieve is one of the most important equipments for 3D printing powder screening. Its simple structure and stable work are widely used in powder related industries. For the ultrasonic vibrating screen, the most important thing is the screening efficiency. Improving the screening efficiency can greatly improve the yield and reduce the fluctuation between powder batches. There are many factors that affect the screening efficiency. This paper takes the die steel as an example to analyze the influence of the feeding rate on the ultrasonic vibration screening efficiency.

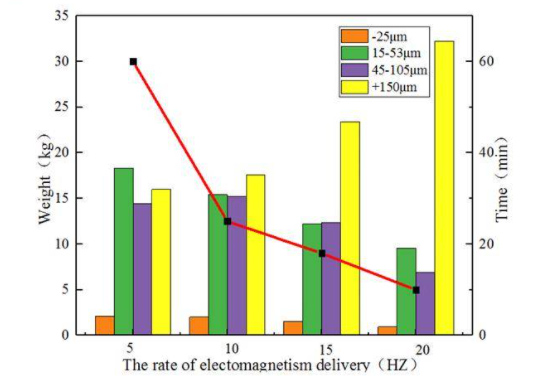

Graph of sieving time and weight change at different feed speeds. It can be seen from the figure that with the increase of the feeding speed, the sieving completion time gradually decreases, the weight of the +105μm particle size section increases continuously, and the particle size of the 45-105μm section continues to decrease. Although the feeding speed is increased, the intensity of screen vibration does not increase, and the height and intensity of the material being thrown remain unchanged. The increase of the feeding speed increases the feeding amount, but when the material exceeds a certain amount, the material layer is too thick, the material particles are not easily loosened, and the sieve holes are blocked, and the particles in the upper part of the material layer are difficult to pass through the sieve holes. The weight of the segment increases significantly. The weights of the 45-105 μm, 15-53 μm and −25 μm particle size segments all decreased as the feed rate increased. Due to the reduction of the material passing through the upper screen, the weight of the corresponding remaining particle size sections will also be reduced accordingly.

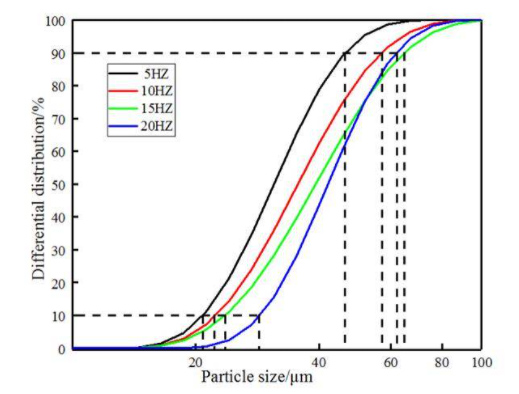

Particle size distribution at different feed rates. With the increase of feed rate, the value of D10 of powder particle size increases continuously, and the value of D90 decreases continuously. When the frequency exceeds a certain value, both D10 and D90 have exceeded the required range of particle size for qualified products. The increase of the feeding speed leads to an increase in the probability of collision between materials, and the agglomerated particles are smashed into separate small particles, which are easier to loosen between particles, and easier to stratify between large and small particles. However, the increase of the feeding speed will also lead to the blocking of the screen, the material with larger particles is blocked by the upper screen, and the particle size of the particles passing through the screen becomes finer.

-

3D Printing Powders Vibrating Sieve

Maintain the size of the mesh port and stabilize the screening accuracy

-

Titanium Alloy Vibrating Screen Screening Solutions

Generally, ordinary ternary vibrating screen can be used for coarse particle screening and impurity removal, and ultrasonic vibrating screen is used for ultra-fine particle alloy po ...

-

What are the common mesh sizes of Battery Anode Materials Vibrating Sieve?

General Battery Anode Materials Vibrating Sieve such as artificial graphite, natural graphite, graphene and other raw materials, lets take graphite as an example, the materials betw ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.