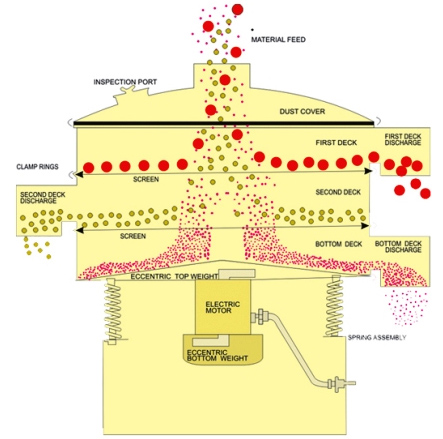

6 advantages of ceramic powder rotary vibrating screen

The main points of ceramic powder rotary vibrating sieve are as follows

1. The ceramic powder rotary vibrating screen should be equipped with electrical protection devices;

2. In the initial stage of operation of the ceramic powder rotary vibrating screen, check the anchor bolts at least once a day to prevent loosening;

3. When the rotation direction of the motor of the ceramic powder rotary vibrating screen does not meet the requirements, adjust the phase sequence of the power supply;

4. The ceramic powder rotary vibrating sieve motor should be well lubricated. Lithium-based grease (ZL-3) should be refilled every two weeks or so. When refueling, add an appropriate amount of lithium-based grease through the oil cup. When using sealed bearings, the motor is not equipped with an oil cup;

5. After the ceramic powder rotary vibrating sieve has been running for 1500 hours, the bearing of the chili powder rotary vibrating sieve should be checked, and if it is seriously damaged, it should be replaced immediately;

6. When the ceramic powder rotary vibrating screen is used again after being parked for a long time, the insulation resistance should be measured. It should be greater than 0.5 megohm for 500V megohmmeter measurement.

In combination with the above content, we also clearly know that because the body of the ceramic powder rotary vibrating screen is a fully sealed structure, we should pay attention to the standard requirements during installation. Only in accordance with the requirements of the standard will we avoid trouble in the future. And after installation, we have to go through debugging before putting it into use, which also avoids the chain reaction caused by some minor problems, which leads to economic losses.

-

Mainly used for powder, granule and liquid materials ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.