Rotary Vibrating Screen

![[field:title/]](/uploads/211115/1-21111516120b18.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

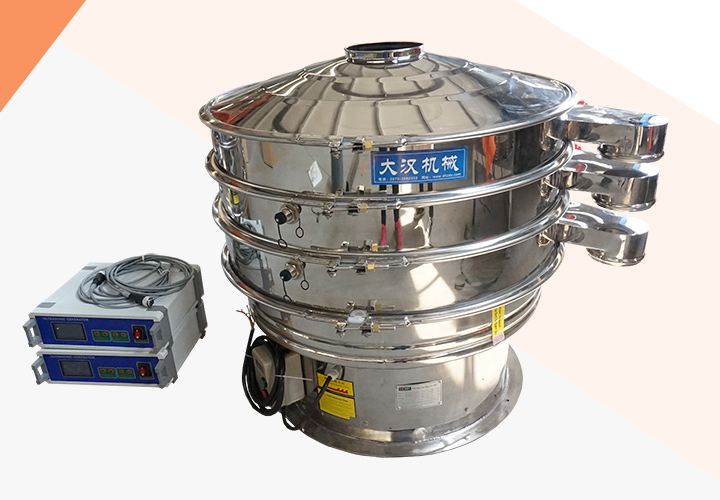

A net cleaning device can be added to reduce material clogging.

There are three materials: carbon steel, stainless steel, and plastic.

1-4 layers of screens can be added according to user requirements.

Introduction of rotary vibrating screen

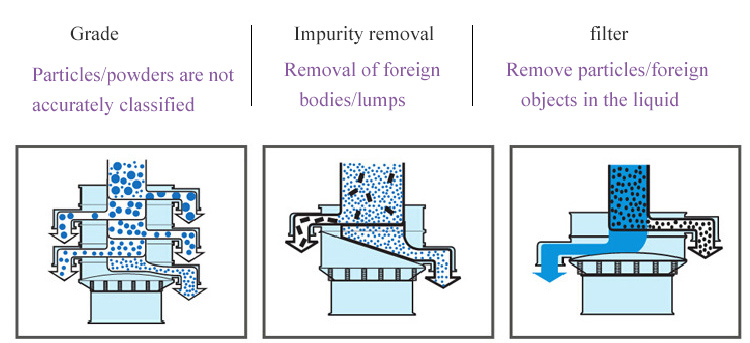

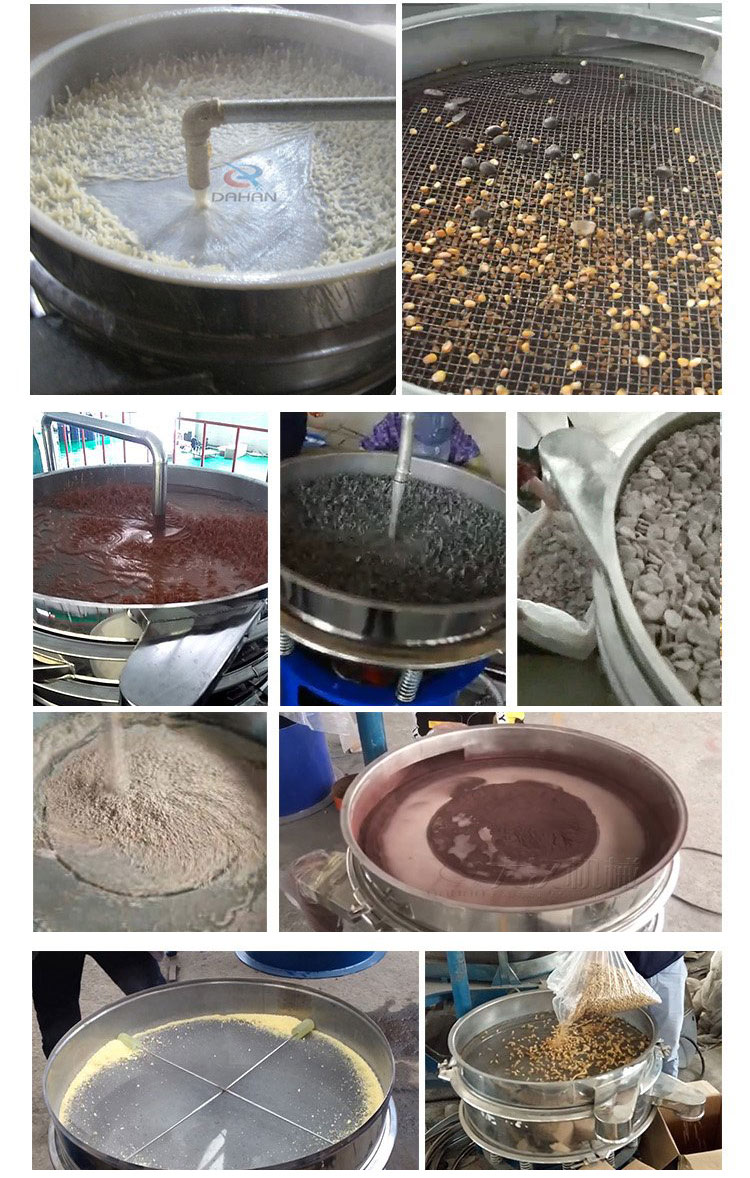

Rotary vibrating screen is used to accurately classify and sort wet material and dry material into 2-6 different parts in one process, it can be used in the separation process of solid in liquid, used for the separation of different particle sizes of the same product, used to eliminate Safe screening of foreign bodies, for homogenization of particles, etc.

The rotary vibrating screen is made of Q235 carbon steel, SS304 stainless steel (or SS316, upon request) and is equipped with a motor with an eccentric mass that produces three-dimensional motion to facilitate the screening of products as much as possible. Adjustment of the mass allows the behavior of the product in the mesh and the screening speed to be adjusted, allowing production of 100 to 5,000 kg/h, depending on the product, mesh and feed flow to the machine. ZEUS circular vibrating screens are suitable for sieving from 36 microns to 25 mm.

Technical parameters of rotary vibrating screen

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Function of rotary vibrating screen

1. Classification: One rotary vibrating screen can be used to continuously and accurately separate and screen the products. Multi-layer use can separate and screen six groups of products with different particle sizes at a time without inconsistent particle size ratios.

2. Liquid removal: This equipment can be used in single layer and multiple layers, which can effectively process solid and liquid mixtures, quickly realize solid-liquid separation, and filter out different target materials.

3. Removal of impurities: This equipment can quickly separate a large amount of materials and remove small parts of materials of different sizes.

Working principle of rotary vibrating screen

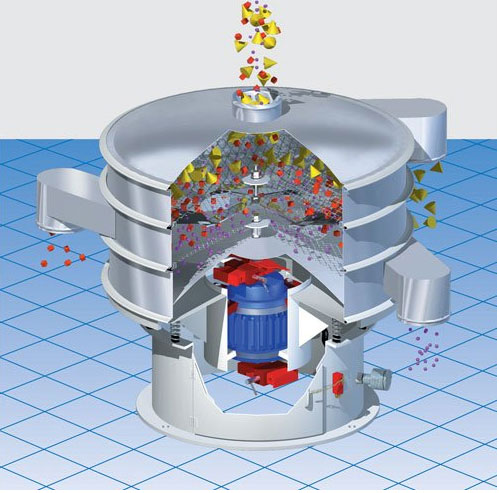

The rotary vibrating screen uses a vertical vibrating motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the motor's rotating motion into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the sieve Screen the noodles. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Benefits of rotary vibrating screen

Improve product quality - eliminate oversize and contamination in powder or liquid slurries

Increased productivity - our screeners have higher throughput than standard vibrating screens

Small footprint - compact form requires minimal headroom and can easily fit into your existing production line

Reduce cleaning downtime - tool-less, quick-release mechanism facilitates removal and cleaning

Eliminate dust and fumes - enclosed sanitary screener ensures complete containment of screened material

Reduced noise levels - rubber suspension system reduces mechanical noise and ensures quiet operation

Featured videos

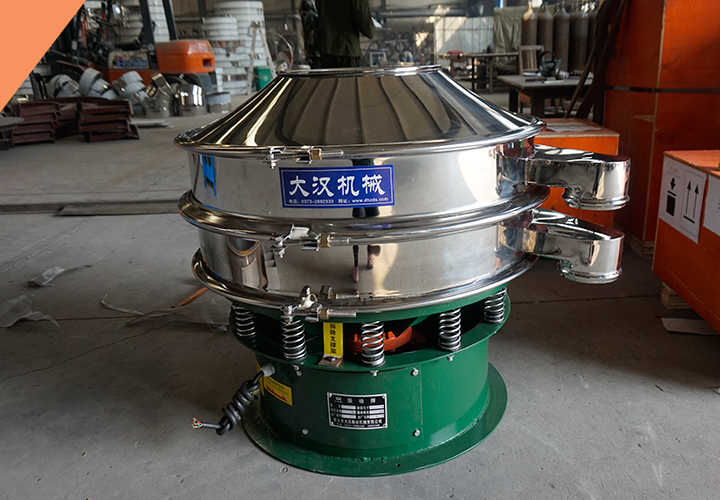

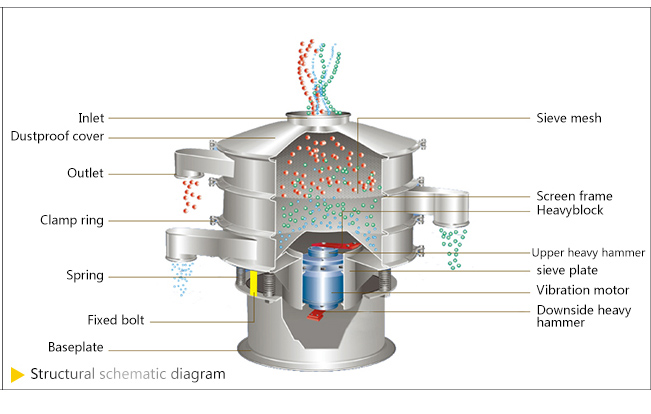

Structure of rotary vibrating screen

Rotary vibrating screen is mainly composed of screen, screen plate, screen cleaning device, screen frame, vibration motor, inlet and outlet, damping spring, etc.

Screen: 304 stainless steel screen, in line with the hygiene standards of food, medicine and other industries, the aperture ranges from 8-500 meshes, which can be selected according to user requirements.

Net cleaning device: equipped with 304 stainless steel punching plate, bouncing ball and ball retaining ring, anti-blocking net and high screening efficiency.

Vibration motor: dedicated vertical vibration motor is the excitation source, no mechanical transmission, high energy efficiency, easy adjustment, reliable quality and high stability.

Damping spring: It plays a buffering role in the working process of the vibrating screen, so that the material can keep moving forward on the screen without damaging the vibrating screen.

Accessories

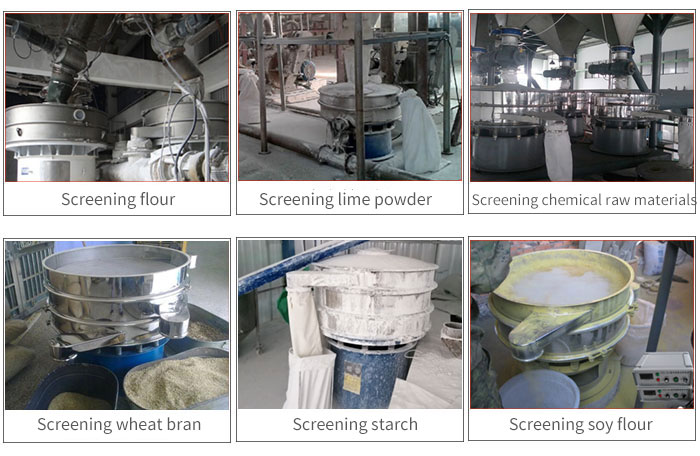

Application of rotary vibrating screen

Chemical industry: resin, paint, industrial vermiculite, cosmetics, paint

Abrasive materials and ceramic industry: alumina, quartz, slurry, kaolin, silicon carbide, sprayer dust.

Food industry: sugar, rice flour, milk powder, soy milk, angel cake, sauce, fruit juice.

Papermaking industry: raw liquid, white mud, black and white liquid, waste liquid, papermaking liquid, waste water recovery.

Metallurgical mining industry: aluminum powder, copper powder, copper powder, ore alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, friction powder, refractory materials, kaolin, lime, heavy calcium carbonate.

Related cases

| PRODUCT | MESH OPENING | DH-600 | DH-800 | DH-1200 | DH-1500 |

| Milk powder | 400µ | 350Kg/h | 800Kg/h | 1.800Kg/h | 2.800Kg/h |

| Orange juice | 1000µ | 1.600l/h | 3.500l/h | 8.000l/h | 12.000l/h |

| Sweet pepper | 1000µ | 180Kg/h | 350Kg/h | 1.000Kg/h | 1.300Kg/h |

| Serum lactic | 50µ | 1.000l/h | 2.200l/h | 5.000l/h | 7.500l/h |

| Sugar glass | 150µ | 800 Kg/h | 2.000 Kg/h | 3.000 Kg/h | 3.500Kg/h |

| Wheat flour | 300µ | 300 Kg/h | 600 Kg/h | 1.350 Kg/h | 2.100Kg/h |

-

Screening, filtering and impurity removal of fine powder, micro powder ...

-

Ultra-fine powder with high fineness, light specific gravity...

-

6 advantages of ceramic powder rotary vibrating screen

The main points of ceramic powder rotary vibrating sieve are as follows 1. The ceramic powder rotary ...

-

Where is the powder sieve purchased?

The particle size of PVC Resin material is between 60-200 mesh, and its specific gravity is relativel ...

-

Types of rotary Industrial sieving machine

Industrial sieving machine is a high-precision screening machine, whether the material is dry or wet ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.