Abrasive Sieve Sifter

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

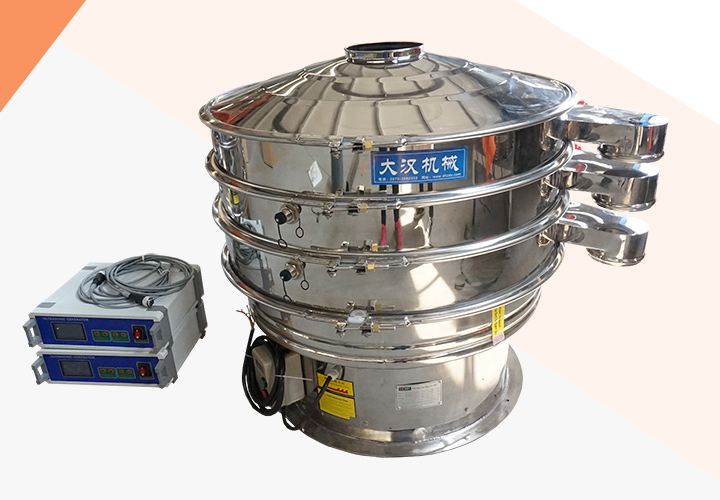

Fully enclosed structure, the powder does not fly.

Automatic discharging, no stock in the machine.

Layers 1-5 can be used at the same time according to different needs of customers

Introduction of abrasive sieve sifter

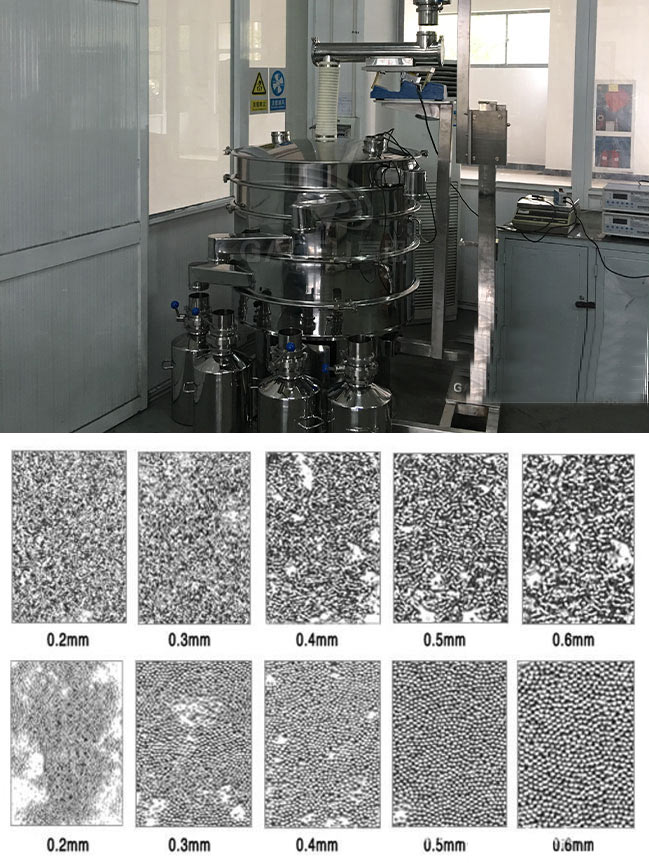

Abrasive processing has very strict requirements on the particle size of the final product. The abrasive professional standard stipulates that the abrasive with a size of 2.0 mm to 0.005 mm is divided into 29 particle size numbers according to the particle size. Abrasive sieve sifter can screen abrasives with different particle sizes. During the screening process , often mixed with small particles of different particle sizes, these particles have adsorption, so it is necessary to install an ultrasonic deblinding system in the screening to prevent the screen from clogging due to adsorption.

Application of abrasive sieve sifter

1. Enterprises that produce micropowder abrasives generally use the following screens with apertures: 0.025mm, 0.036mm, 0.045mm, 0.053mm, 0.063mm, 0.071mm, 0.075mm (500~200 mesh), and the state-owned May Fourth The screen mesh produced by the zero factory is the main one. Due to specification lower than

There are few 0.025mm sieves in the market, so for fine powders below 0.015mm (15 microns), generally use sieves with apertures of 0.025mm and 0.036mm, equipped with S49-AC-1000 ultrasonic vibrating sieve, the output can be Up to 200~1000kg/h.

2. Due to the particle size and shape of the abrasive, the screening output is generally not guaranteed. For example, if a screen with a hole diameter of 0.063mm is used, materials with a particle size of less than 50 microns can easily pass through the screen, and the output can be guaranteed. Therefore, the particle size of the material should be 7-12 microns smaller than the mesh size, so that the screening output can be satisfied, and the screening rate will also increase accordingly. In addition, some enterprises require the micropowder to be 2000~5000#. Generally, the micropowder is filtered out by water buoyancy (water separation method) and then dried, and then the ultrasonic vibrating screen (400 mesh screen is installed) is used to remove impurities or shake loose The multi-molecular coagulation formed during the drying process can reach about 1000kg/h (2000# particle size is 6.7±0.6 microns).

If you are planning to add equipment, please be sure to describe the characteristics of the material clearly, and then communicate with experienced engineers or professional technicians in detail, and even conduct routine experiments, so as to meet your needs and achieve the screening effect you need.

| Material | Proportion | Mesh | Processing method | Capacity (kg/hr IT/hr) |

Model |

| Emery | 4 | 60 | Wet | 300㎏ | DH-1000-1S |

| Grinding powder | 0.8 | 40 | Wet | 1200kg | DH-1200-1S |

| Electrode powder | 0.95 | 20/200 | Wet | 550㎏ | DH-1000-2S |

| Quartz sand | 2.65 | 140 | Wet | 2000kg | DH-1200-3S |

Featured videos

-

Remove foreign matter in abrasive

-

Separate abrasives of different thicknesses

Abrasive sieve sifter screening, grading process

Driven by the vibrating motor, the abrasive put on the screen moves up and down at a constant speed. The first layer sieves materials larger than the sieve, and the second layer sieves materials smaller than the first layer mesh but thicker than the second layer mesh. If our machine is 80 mesh and 100 mesh, the sieved material is relatively small. A grade of 80 mesh coarse, a grade of powder between 80-100 mesh, and a grade finer than 100 mesh.

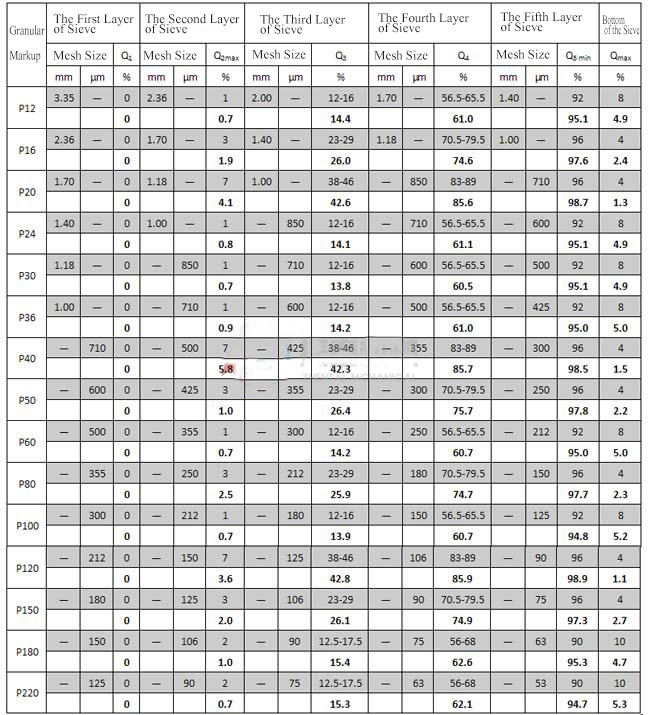

Therefore, it is necessary to use a vibrating sieve to divide the abrasive into grades of different specifications. Each layer of screen frame should be equipped with screens of different meshes for screening. Below is the standard sand (P-standard sand) of coarse abrasive grain size for abrasive tools.

Benefits of abrasive sieve sifter

1. It can screen up to 500 meshes, with various sizes (from 400mm to 2000mm), meeting the screening needs of different industries, and the output is from 100 to 3300kg/h.

2. According to actual production needs, it can be used in single or multiple layers, and can screen one to five layers of screens, and can simultaneously perform two to six levels of sorting.

3. The discharge port can be set arbitrarily at 360° around the axis, which is conducive to the arrangement of supporting equipment.

4. According to the actual needs of users, it can be customized and added to the existing production system to realize automatic production. At the same time, it can be equipped with special dust removal equipment developed by Dahan to ensure a clean and environmentally friendly production environment and avoid abrasive waste.

Technical parameters of abrasive sieve sifter

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Abrasive sieve sifter customer site

-

Used for screening, classifying and removing impurities in various powder ...

-

Suitable for screening and filtering of granules, powder, mucus and other materials ...

-

Ultra-fine powder with high fineness, light specific gravity ...

-

How is the abrasive sieve sifter used in the process

Abrasive sieve sifter , the abrasive can be divided into four groups according to its particle size: ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision and high e ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles, powders and mucus with ...

-

What is the price of sesame vibro sifter?

Q: How much is the sesame vibro sifter? A: The price of sesame vibro sifter of Xinxiang Dahan Factory ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.