How is the abrasive sieve sifter used in the process

Abrasive sieve sifter, the abrasive can be divided into four groups according to its particle size: abrasive grain, mill powder, micro powder and superfine powder. Among them, the particle size numbers of the two groups of abrasive grains and grinding powders are expressed by the number of meshes per inch of screen length, and the mark is to add a "#" symbol to the upper right corner of the particle size number. For example, 240# means that there are 240 holes in each inch of the screen length. The larger the value of the particle size number, the finer the abrasive grains. The particle size numbers of the two groups of micropowder and superfine powder are expressed by the actual size of the particles, and the mark is to add a letter "W" in front of the particle size number. Sometimes it can be converted into a mesh number. For example, W20 means that the actual size of the abrasive particles is between 20μm and 14μm, which is the same as the mesh number 500#.

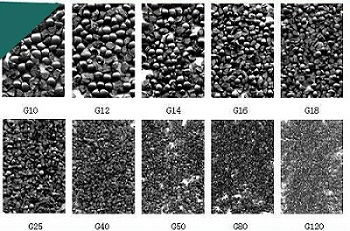

There are coarse, medium, and fine particles in the particle size of various abrasives. The medium particle is the basic particle size in the grinding powder, and it is the main factor that determines the grinding ability of the abrasive. It occupies a large proportion in the composition of Lido. Practice has proved that the grinding capacity of the ground powder after being sorted by the sieving machine will be 20% higher than that before the sorting. Fine particles play a very small role in grinding. The particle size is not only detrimental to the quality of the grinding workpiece, but also reduces the grinding efficiency. The number of them should be minimized in the particle size composition. Therefore, in terms of the efficiency of grinding and the quality of work, the abrasive particles are required to be uniform. The abrasive grain group with a particle size of 12#~80# has a larger particle size and is not suitable for abrasive processing.

In the process of abrasive grading, it is necessary to pass through a rotary vibrating screen for classification. The abrasive rotary vibrating screen is a kind of high screening efficiency, exquisite and durable design, and both fine and mucus can be screened. It is easy to change the screen, easy to operate and easy to clean. The mesh will not be blocked, the powder will not fly, and it can be sieved to 500 mesh or 0.028mm.

The rotary vibrating screen is a high-precision fine powder screening machine. The working principle is that the vertical motor is used as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the rotation of the motor into horizontal, vertical, and inclined The three-dimensional movement of the machine, and then transfer this movement to the screen surface. Adjusting the phase angle of the upper and lower ends can change the trajectory of the material on the screen surface. Because of its vibration operation principle, many companies also call it "three-dimensional vibrating screening filter", which is called a circle by some customers based on its shape and structure. The shape of the vibrating screen is divided into standard type and ordinary type. The standard type is made of 304 stainless steel, the base is made of carbon steel, and the general type is made of plain carbon steel.

-

The finest sieving is 500 mesh (0.028mm).

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision and high e ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles, powders and mucus with ...

-

What is the price of sesame vibro sifter?

Q: How much is the sesame vibro sifter? A: The price of sesame vibro sifter of Xinxiang Dahan Factory ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.