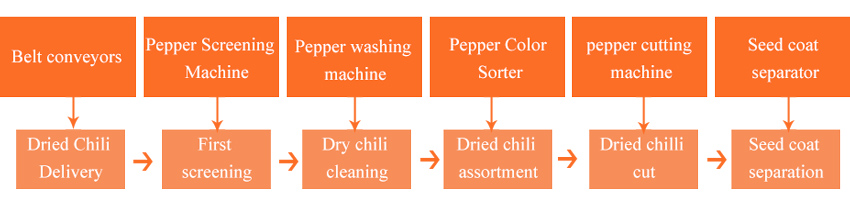

Chili powder vibration sieve screening device process

Chili powder is red or red-yellow, oily and uniform powder. It is a mixture of red chili, yellow chili, chili seeds and some chili stems. It has the inherent spicy flavor of chili and is pungent. sneeze. The authentic one should be pounded with a stone mortar, or you can use dried chili directly, put it in the sun, or dry it in a pot with a slow fire and pound it into a powder.

Dry chili powder needs to be screened by a screening device in the production and processing process, but the screening device in the prior art has the following drawbacks:

1. Chili powder vibration sieve The existing screening device has a single function and only has one or one screening method. The working efficiency of this screening device is not high, does not meet the needs of use, and is gradually eliminated;

2. The structure of the existing screening device is usually integrated. During the use process, the screening disc is prone to blockage. If this happens, the device is very troublesome to handle.

A grading and screening device for dried chili powder is provided to solve the problems raised in the above background technology.

In order to achieve the above purpose, the present invention provides the following technical solutions: a dry chili powder grading and screening device, comprising a screening device body, the screening device body is a hollow structure, the screening device body is provided with a cavity, and the screening device The upper end of the device body is fixedly connected with one end of the sealing frame plate, an opening is formed between the upper end of the screening device body and one end of the sealing frame plate, the opening is provided with an electric push rod, and the upper end of the electric push rod is fixedly connected and sealed the frame plate, the pushing end of the electric push rod is fixedly connected to the middle of the upper end of the first partition plate, the first partition plate is located in the cavity, and the left and right sides of the first partition plate are both connected to one end of the inclined plate Fitting connection, the number of the inclined plates is two, one end of the two inclined plates is fixedly connected to the top surface of the cavity, and one side of the other end of the two inclined plates is provided with an inclined slot, and the inclined slot is One end of the clamping block is embedded, and the other end of the clamping block is fixedly connected to one end of the guide vertical rod. One side of one end of the guide vertical rod is provided with a limit protrusion, and the limit protrusion is inserted into the middle part of one side of the second partition plate. In the jack, the second partition plate is located below the first partition plate, and a first collection tray and a second collection tray are arranged below the second partition plate, and the first collection tray and the second The mechanism of the collection tray is the same, and the left side of the first collection tray and the right side of the second collection tray are both fixedly connected to one end of the linkage rod.

Preferably, a first leakage hole is formed through the first partition plate, a second leakage hole is formed through the second partition plate, and the number of the first leakage hole and the second leakage hole is are not less than four.

Preferably, a motor is fixedly installed in the middle of the lower end of the first partition plate, a fixing ring is sleeved on the outer side of the rotating shaft of the motor, and the outer side of the fixing ring is fixedly connected to one end of a screening stirring rod, and the screening stirring rod The number is not less than four, and the screening and stirring rods are arranged along the outer annular array of the fixed ring.

Preferably, the number of the linkage rods is two, the other ends of the two linkage rods are connected to the side walls of the cavity through the hinge seat, and the upper sides of the other ends of the two linkage rods are provided with through hole.

Preferably, one end of the limiting column is inserted into the through hole, one end of the limiting column is connected with the through hole through internal and external threads, and the other end of the limiting column penetrates one end of the extending horizontal plate and is fixedly connected One end of the knob and the other end of the extending horizontal plate are fixedly connected to the side wall of the cavity, and the extending horizontal plate is located above the hinge seat.

Chili Powder Screening Process

1. The set electric push rod drives the first partition plate to move up and down, so that the first partition plate has a shaking and screening effect on the dried chili powder, and the set screening stirring rod has a stirring and screening effect on the dried chili powder. , the function is strong, the first collection tray and the second collection tray are set to collect the dried chili powder screened in different ways, and the division of labor is clear, which makes the overall equipment work efficiently;

2. The position of the second partition plate is limited by the guide vertical rod, which is convenient for the disassembly and assembly of the second partition plate. When the second partition plate is blocked, move the second partition plate outward to The detachable second partition plate has fast processing time, and solves the deficiencies in the prior art very well.

-

You can achieve 6 different gradation in a single operation as it can be structured up to 5 decks.

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.