Circular Vibrating Screen

![[field:title/]](/uploads/211112/1-211112112053251.jpg)

Callback

| Screen size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

Classification: The powder and particles can be accurately classified into 2-5 grades, with an accuracy rate of more than 95%.

Impurity removal: remove agglomerated or unqualified materials from the materials, with an accuracy of more than 98%.

Filtration: Removal of particles/foreign objects in liquid materials, with a filtration capacity of 5 tons/hour.

Introduction of circular vibrating screen

The circular vibrating screen is named after the appearance of the screen. Its base, screen frame and grid frame are all circular. The vertical vibrating motor is used as the vibration source. The material spreads outward in a spiral on the screen surface. Screen powder or fine particle materials, divided into three materials: carbon steel, stainless steel, and plastic. There are 1-5 layers of screens, and one material can be separated into 2-6 different particle sizes at the same time.

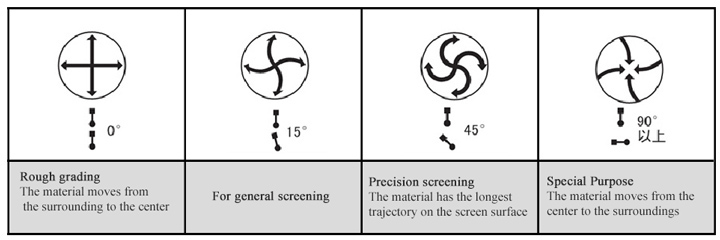

Working principle of circular vibrating screen

After the circular vibrating screen is started, its power device is the eccentric masses with different phases at the upper and lower ends of the vibrating motor. Due to the high-speed placement, a composite inertial force is generated. Continuously reciprocating movement under the action of the ground, driving the screen surface to periodically vibrate, so that the material on the screen surface will move directional and enthusiastically along with the screen box, during which the material smaller than the aperture of the screen surface will fall to the lower layer through the screen hole , Becomes the under-screen material, the material larger than the aperture of the screen surface is discharged from the discharge port after continuous jumping motion, and the screening work is finally completed.

Benefits of circular vibrating screen

1. It is used to screen powder or fine particle materials, and it can also remove impurities in liquid.

2. The mesh of the screen surface is relatively fine, which can screen materials well but is not easy to be blocked. It can be screened to 500 mesh or 0.028mm.

3. Adopt a closed working environment to ensure that the materials are not disturbed by external factors during screening and no dust pollution.

4. you can achieve 2-6 different gradation in a single operation as it can be structured up to 5 decks.

5. Automated processing of impurities and coarse materials after screening, saving labor, after screening, you can enter the next round of screening work by yourself for continuous operation.

Featured videos

-

Sieving graphite powder

-

Filter liquid filler

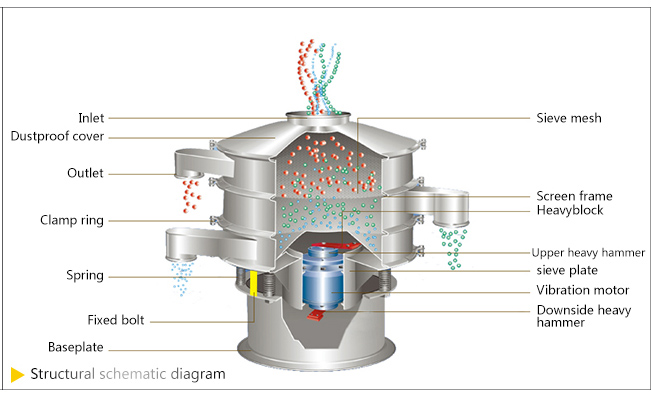

Structure of circular vibrating screen

The circular vibrating screen is mainly composed of dust cover, screen frame, beam ring, screen, punching plate, cleaning device, vibrating motor, bottom barrel, vibrating plate and other parts.

Dust cover: to prevent the escape of dust.

Vibration motor: Vertical vibration motor is used, and the motor power can be selected from 0.18KW to 4.0KW. (The larger the diameter of the device, the greater the power of the motor used). For some special industries, explosion-proof vibration motors can be equipped.

Screen frame: Constrain the material to make the material produced within a certain range. Common materials are Q235 carbon steel and 304 stainless steel, and the thickness of the material is 2.0mm~3.0mm.

Beam ring: connect the bottom cone and the screen frame, the upper and lower screen frames, and also play a role in preventing material leakage.

Screen: The parts that are in direct contact with the material. The commonly used material is 304 stainless steel woven mesh.

Punching plate: Lift the screen to extend the service life of the screen. The commonly used material is 304 stainless steel.

Net cleaning device: It can be divided into three types of net cleaning devices: bouncing ball, ultrasonic, and rotating brush. Users can choose reasonably according to different production processes.

Bottom bucket: the parts that support the screen body and carry the vibration motor, the thickness is 3mm~6mm, and the thickness is also determined by the diameter of the equipment.

Vibrating plate: It has the function of fixing the vibrating motor and connecting the screen body. The plate used is Q235 carbon steel with a thickness of 4mm~6mm.

Technical parameters of circular vibrating screen

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

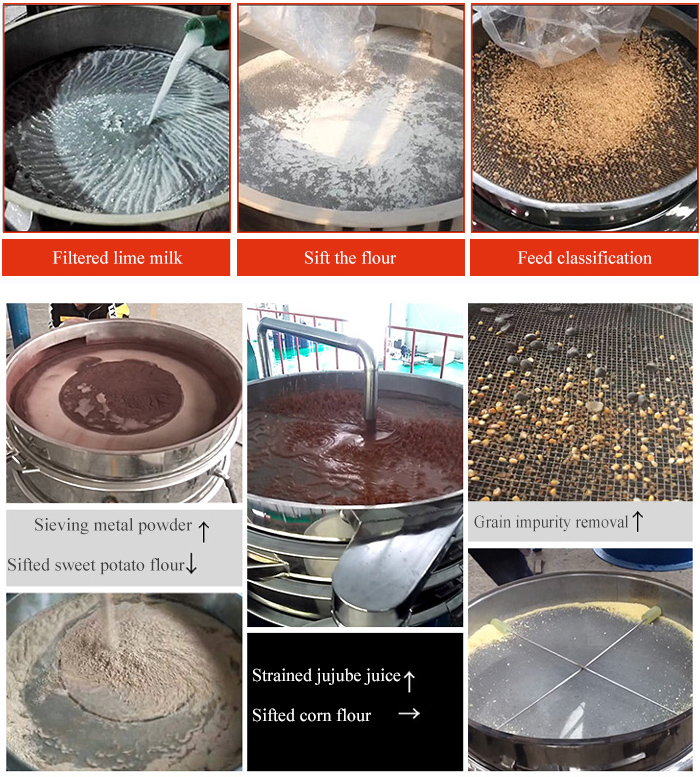

Application of circular vibrating screen

Food industry: wheat, soybeans, corn, starch, wheat flour, fruit juice, soy milk, soy sauce, etc.

Chemical industry: resin powder, rubber powder, paint, paint, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid, Chinese and western medicine granules, etc.

Metallurgical industry: alumina, quartz sand, mud, sprayed soil particles, titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Other industries: coating paint, waste water, waste oil, papermaking liquid, waste water recycling.

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | 250 | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Medicine powder | 0.8 | 80 | DH-800-1S | Dry | 550㎏ |

| Iron powder | 3 | 400 | DH-800-1S | Dry | 230㎏ |

| Emery | 4 | 60 | DH-1000-1S | Dry | 300㎏ |

| Spray soil particles | 2 | 10 | DH-1000-1S | Dry | 18000㎏ |

| Mica | 0.8 | 200 | DH-800-1S | Dry | 110㎏ |

| Waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000IT |

| Dyeing and steaming wastewater | 1 | 150 | DH-1000-1S | Wet | 22000IT |

| Waste oil | 0.9 | 100 | DH-1000-1S | Wet | 3800IT |

Related cases

-

It is convenient and quick to change the screen.

-

Can be used for grain, powder, granule and liquid.

-

What kinds of common circular vibrating screens are there

Circular vibrating screen is a common type of vibrating equipment on the market. It is named after it ...

-

The working principle of circular vibrating sieve

Vibrating screens are divided into Circular Vibrating Sieves, linear vibrating screens...

-

Circular sieve manufacturers

Because there are demand, there are many manufacturers of circular sieves on the market. ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.