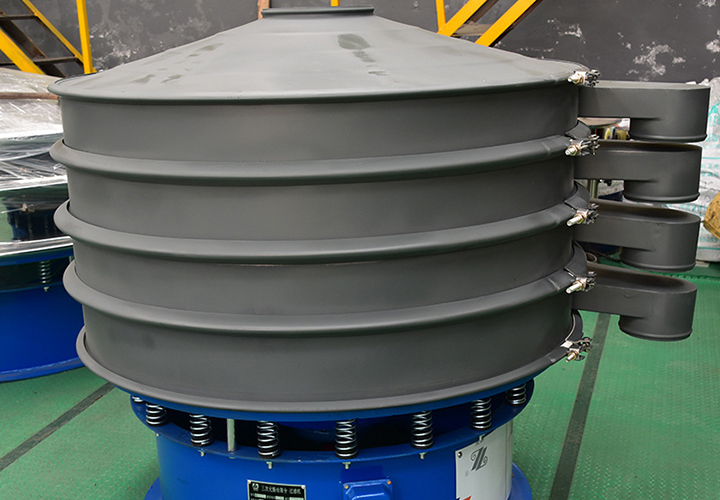

Plastic Powder Vibratory Sifter

Callback

| Screen size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

The sorting grades of plastic powder are as follows: Coarse flour: 5-60 mesh Medium powder: 60-160 mesh Fine powder: 160-300 mesh Superfine powder: 300-500 mesh

Introduction of plastic powder vibratory sifter

The plastic powder is a polyvinyl chloride plastic, a vinyl polymer, with bright color, corrosion resistance, and durability. At present, it is widely used in pipe, film, sheet and other fields in China. Plastic powder vibratory sifter can remove impurities and agglomeration in plastic powder. According to the specific needs of users for screening materials, Plastic powder vibratory sifter can be divided into one layer and two layers , Three-layer and four-layer PVC powder vibrating screen. Standard type, ultrasonic type, flanged type, gate type, etc. can be customized according to different user needs. The screen machine is made of stainless steel and carbon steel.

Classification of plastic powder vibratory sifter

A. Standard plastic powder vibratory sifter: suitable for classification of crushed and shaped plastic particles or to remove impurities and agglomeration.B. Ultrasonic type plastic powder vibratory sifter:Ultra-fine plastic powder is more difficult to sieving because it is easy to generate static electricity and cause it to stick to the screen. This type of plastic powder vibratory sifter uses ultrasonic frequency to vibrate the screen, which can prevent the holes from being blocked and make it easier to screen For powder, the screening capacity is increased by up to 10 times, while allowing the separation accuracy as low as 20 microns (#635 mesh).

B. Ultrasonic type plastic powder vibratory sifter: The strong vibration type PVC powder vibrating sifter is 2-4 times the vibration acceleration of the standard type plastic powder vibratory sifter. In the process of sieving materials, the output can be guaranteed 2-4 times of the same model .

Application of plastic powder vibratory sifter

Some plastics can be directly obtained in powder form by crystallization in the synthesis process, but most of them are about 300um rubber powder, and some plastics can also get about 300um rubber powder through spray granulation.

Coarse powder, medium powder, fine powder, and ultra-fine powder are used in different requirements. Among plastic powder particles, coarse powder generally refers to powder with 5 to 60 mesh, and medium powder refers to powder with 60 to 160 mesh. The fine powder is from 160 mesh to 300 mesh, and the above 300 mesh belongs to superfine powder. However, the classification of coarse, medium, fine, and superfine is different according to the degree of easy crushing of different raw materials.

Working principle of plastic powder vibratory sifter

The lastic powder vibratory sifter uses the YZUL vertical vibration motor as the excitation source, and uses the eccentric weights at the upper and lower ends of the vibration motor to convert the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, which is transmitted to the screen surface of the rotary vibrating screen; The material enters the equipment through the inlet. According to different material screening requirements, the material passes through the 1-5 layers of sieving with different mesh metal woven screens. In this process, the cleaning is located under the screens of each layer. The net device (bouncing ball) constantly hits the screen through frequency vibration, so that the materials on the screen can be smoothly screened through the screen, and effectively solve the problem of material blocking, and the materials of different meshes pass through the screens of the corresponding meshes in each layer. After the net, it is discharged at the discharge port of each layer, and finally achieves the purpose of screening and removing impurities or filtering and grading.

Featured videos

-

Sieving 60 mesh plastic powder

-

Sieving 180 mesh plastic powder

Benefits of plastic powder vibratory sifter

Improve your product quality - eliminate oversized contaminants in powders

6-stage separation - plastic powder can be screened through 1-5 layers of sieves with different apertures to separate coarse powder and fine powder to ensure accurate particle size classification

Reduced cleaning downtime - The unit can be easily disassembled without tools. All contact parts are fully washable

Protects operator health and safety - closed structure prevents product leakage, which protects operators from harmful dust

Small Footprint - The compact size meets industrial and commercial needs with minimal headroom and floor space, and fits comfortably into any production line.

Technical parameters of plastic powder vibratory sifter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Related cases:

| Materials | Proportion | Mesh | Processing Method | Capacity (kg/hr IT/hr) |

Model |

| Epoxy resin | 1.8 | 100 | Dry | 280㎏ | DH-1000-1S |

| MBS resin | 0.3 | 30 | Dry | 350㎏ | DH-800-1S |

| Melamine resin | 0.4 | 30/60 | Dry | 36㎏ | DH-600-2S |

| PVC resin | 1 | 10㎜/5㎜ | Dry | 3000㎏ | DH-1200-2S |

| Polyethylene powder | 0.45 | 48/100 | Dry | 100㎏ | DH-800-2S |

| Polyethylene resin | 0.5 | 60 | Dry | 450㎏ | DH-1000-1S |

| Aggregate particles | 1.05 | 10-20 | Dry | 3100㎏ | DH-1000-2S |

| Spray paint | 1.1/1.2 | 325 | Wet | 600IT | DH-600 |

| Magnetic pigment | 5 | 100 | Dry | 450㎏ | DH-600-1S |

| Acrylic powder coating | 0.5-0.8 | 80 | Dry | 180㎏ | DH-800-1S |

| Non-magnetic pigment | 0.4 | 60 | Dry | 120㎏ | DH-1000-1S |

| Epoxy powder coating | 5.0/0.8 | 80 | Dry | 450㎏ | DH-800-1S |

| Polyester powder coating | 0.6/0.8 | 100 | Dry | 400㎏ | DH-1000-2S |

-

Vibratory Sifter for Plastic Pellets

Remove impurities and agglomerates in the plastic particles, or classify the molded plastic particles

-

Innovative high-enclosed sieving machine can accurately remove excessive contaminants in the powder

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers, and 6 different grades of graphite powder can be ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.