Diatomaceous Earth for Powder Sieving Machine

Diatomaceous earth is a natural inorganic material formed from the remains and debris deposits of marine algae. It has good adsorption performance, pore structure and chemical stability, and is widely used in building materials, ceramics, coatings, cosmetics and other fields. In the production process of diatomite, screening is a key link, and the diatomaceous earth for powder sieving machine is an important equipment to achieve diatomite screening.

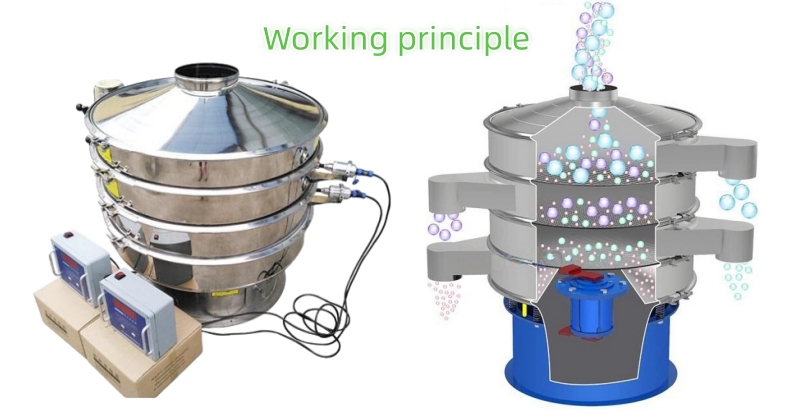

The diatomaceous earth for powder sieving machine is a device specially used for screening powder materials. It can complete the screening task of diatomaceous earth efficiently and accurately. Its working principle is based on the action of vibration force and screening mesh. First, the diatomite powder to be screened is introduced into the screening chamber through the feed port. There is a screen in the screening chamber, and the aperture of the screen can be adjusted as needed. Next, through the vibration drive device, the screening machine generates high-frequency vibration to quickly transport and screen the diatomite powder on the screen. According to the screening results, diatomite powder particles of different particle sizes are collected and separated through different discharge ports.

Diatomaceous earth for powder sieving machine has multiple advantages in the production of diatomaceous earth. First, it can achieve particle size control of diatomite powder particles to ensure product consistency and quality stability. By adjusting the screen aperture, diatomite powder can be classified to meet the different particle size requirements of different industries. Secondly, the powder screening machine can effectively remove impurities and particle clumps in diatomite powder and improve the purity and uniformity of the product. This is of great significance for the subsequent processing and application of diatomite powder. In addition, the screening machine can also improve production efficiency, reduce manual operations, and reduce production costs.

During the diatomite screening process, some technical details also need to be paid attention to. First, control the vibration frequency and amplitude of the powder sieving machine to ensure the transmission and screening effect of diatomite powder on the screen. Too large or too small amplitude will affect the screening effect and the life of the equipment. Secondly, according to the characteristics and humidity of diatomite, appropriately adjust the feeding speed and screening time of the powder sieving machine to obtain the ideal screening effect. In addition, the wear of the screen mesh should be checked regularly and severely worn screens should be replaced in a timely manner to ensure the screening effect and product quality.

Through the operation of powder sieving machine, the control of diatomite particle size and the removal of impurities can be achieved. Reasonable selection and use of screening equipment can improve the quality and consistency of diatomite products and meet market demand. At the same time, regular maintenance and maintenance of the powder sieving machine ensures the normal operation of the equipment and extends the service life of the equipment.

-

Removes all oversized contamination or agglomerates from powder ...

-

Powder Sieving Machine for epoxy

Resin refers to a general term for a class of polymers containing two or more epoxy groups in a molec ...

-

metal powder sieving machine solution use

Achieving accurate particle size distribution is critical in all areas of metal powder production ...

-

metal powder sieving machine price

After choosing the model of the metal powder sieving machine for the customer, its price becom ...

-

Diatomaceous Earth for Powder Sieving Machine

The application of Powder Sieving Machine in the field of Titanium Dioxide has the advantages of efficient screening. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.