Powder Sieving Machine

Callback

| Mesh size: | 2-500 mesh |

| Capacity: | 100-3300 kg/h |

| Power: | 0.25-3KW |

Removes fine-grained or oversized contaminants

Fully enclosed structure with dust-free and hygienic operation

Made of 304 and 316 stainless steel, resistant to powdering, easy to clean and sterilize

Introduction of powder sieving machine

Powder sieving machine is designed for high volume sieving of powders to remove oversized contaminants and agglomerates, easily integrated into your production line, widely used in food powders, pharmaceutical powders, chemical powders, coating powders and Industries including metal powders, enable high throughput and are available in different sizes from 600mm to 2000mm diameter for batch or continuous processing to suit your production requirements.

Application of powder sieving machine

1.Powder Sieving: A wide range of powders can be screened, dusted and classified, eliminating any unwanted solids and ensuring consistent and reliable handling.

2.Powder Recovery: Recycling any excess powder left after production ensures that contaminants such as large particles and agglomerates are removed from the powder, providing an accurate particle size distribution.

3.Powder Classification: The powder produced by the ball mill needs to be separated by the powder sieving machine to meet the particle size standard and the insufficiently ground powder, and the particle size of the powder for different purposes also has different standards. According to the different requirements of different application industries for powder particle size, it can be divided into coarse powder (150-500μm), medium powder (44-150μm), fine powder (10-44μm), very fine powder (0.5-10μm) and ultrafine powder Powder (<0.5μm) and other 5 grades.

Common types of powder sieving machine

Powder sieving machines are used in many industries to protect the quality of powder products by removing excessive contamination. These machines are designed for high volume sieving to increase productivity and minimize maintenance costs. We offer a range of options to meet your screening requirements.

-

A wide range of powders can be sieved, dusted and classified, eliminating any unwanted solids and ensuring consistent and reliable handling. We can offer screening machines in a variety of single- or multi-layer configurations for batch or continuous processing.

-

Ultrasonic deblinding systems are used to eliminate mesh blindness when screening difficult powders, using ultrasonics allows you to sieve on a 20μm mesh, making it easier to separate fine powders such as metal powders, paints, chemicals or food powders.

-

Closed systems can be purged with inert gas to isolate contamination-sensitive powders from ambient air and moisture, reducing powder cross-contamination and ensuring a safer environment, commonly used in 3D printing powder recycling systems.

Featured videos

Ensure quality by inspecting and removing foreign contaminants and oversized materials from products

Benefits of our powder sieving machine

Improve product quality - removes all oversized contaminants from your powders and liquids, capable of sieving up to 500# and delivering the desired output to provide accurate particle size.

5-level classification - provides up to 5 classifications in one operation for precise particle size distribution

High throughput - it is able to screen fine sieves at a faster speed compared to standard sieving machines, the application works on the principle of three-dimensional motion, this powder sieving machine produces 3 times more vibrations compared to traditional sieving machines And provide higher throughput in ultra-fine screen.

Low height and small footprint - thanks to its compact design, this sieving machine can be easily installed in tight spaces and can be easily integrated into your production line.

Keeps Operators Safe - Totally enclosed unit prevents dust and fumes from leaking.

Explosion-proof - The explosion-proof design can prevent explosion accidents caused by excessive dust density.

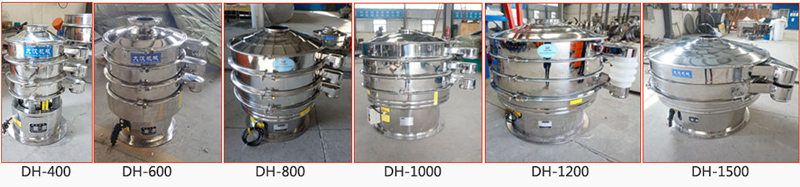

Technical parameters of powder sieving machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

How powder sieving machine helps different industries

| Material picture | Material name | Material characteristics | Advantages of powder sieving machine——Material consultation |

|

Silicon carbide | High hardness, small expansion coefficient, brittleness, good thermal conductivity, etc. | The small impact force and small vibration ability can prevent the silicon carbide from being damaged by the vibration ability during the screening. |

|

Wood flour | Light specific gravity, fluffy material, easy to agglomerate | The high vibration frequency can suppress clumping and fluffy problems. |

|

Lithium battery materials | It has good electrical conductivity and anti-classical properties, light weight, poor material fluidity, high viscosity, low output | solve the problem of powder proportion, low material flowability, high viscosity, low output and low screening |

|

Chinese medicine powder | light specific gravity, easy to clump, easy to adhere | Fully sealed screening method, high-frequency screening can solve screening problems such as small particle size, light weight, and easy suspension |

|

Epoxy powder | a thermosetting powder coating with corrosion resistance and toughness | solve the problem of low powder proportion, corrosion resistance and long service life |

|

Nickel Ternary Cathode Material | High capacity, low cost, poor material fluidity, high viscosity, low output | Solve the problem of poor fluidity of materials, high viscosity, low yield and low sieving |

|

Sulfur powder | Flammable, disinfection and sterilization, laxative. The fineness is 200 mesh, 325 mesh, 400 mesh and 500 mesh, etc. | Solve the problem of low powder specific gravity, product corrosion resistance and long service life |

|

Graphite powder | Adsorption, easy to clump, strong viscosity, high static electricity and other characteristics | Solve the screening problems of easy clumping, strong viscosity, high static electricity, ultra-fine powder, etc. |

|

coating | Sticky and light, agglomerate into particles, sometimes dusty, waste raw materials and pollute the environment | Fully enclosed screening structure solves the screening problem of sticky and light, agglomerated particles |

Related cases of powder sieving machine

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| Pollen | 0.4 | 12 | DH-1500-1S | 100㎏ | |

| Milk powder | 0.57-0.8 | 12 | DH-1000-1S | 1600㎏ | |

| Powdered sugar | 0.5-0.8 | 100 | DH-800-1S | 200㎏ | |

| corn starch | 0.6 | 40 | DH-1000-1S | 1600㎏ | |

| Medicine powder | 0.8 | 80 | DH-800-1S | 550㎏ | |

| Polyethylene powder | 0.45 | 48/100 | DH-800-2S | 100㎏ | |

| Lead powder | 11.34 | 10/80 | DH-1000-2S | 1000㎏ | |

| Aluminum powder | 0.9/1.2 | 80/120 | DH-800-2S | 350㎏ |

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers ...

-

The screening output per hour can reach 100kg-1t ...

-

Which manufacturer's powder sieving machine is better?

The powder industry chooses to use a vibrating screen for screening. Which manufacturer's powder sieving machine ...

-

Powder Sieving Machine for epoxy

Resin refers to a general term for a class of polymers containing two or more epoxy groups in a molec ...

-

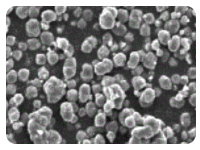

metal powder sieving machine solution use

Achieving accurate particle size distribution is critical in all areas of metal powder production ...

-

metal powder sieving machine price

After choosing the model of the metal powder sieving machine for the customer, its price becom ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.