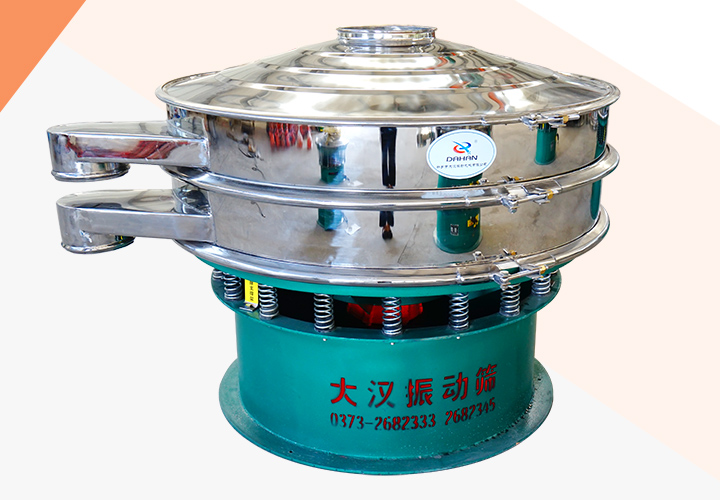

Difference between single vibro sifter and multi-layer vibro sifter

vibro sifter is divided into single vibro sifter and multi-layer vibro sifter according to the screening needs of users. The following explains the difference between these two vibro sifter:

1. The screening levels of materials is different

A single vibro sifter can only screen out 2 different grades of materials, while a multi-layer vibro sifter can screen out a variety of different grades of materials, you can achieve 2-6 different gradation in a single operation as it can be structured up to 5 decks.

2. Different processing capacity

The material screening output is directly related to the diameter of the screen, that is, the contact area between the material and the screen. The diameter of the single vibro sifter will be larger than that of the multi-layer vibro sifter in design, so the screening capacity of the single vibro sifter is larger than that of the multi-layer.

3. The feeding amount is different

The screening capacity of the material is directly related to the size of the material to be fed. Since the single vibro sifter only handles one material, it can be appropriately increased when feeding. Since the multi-layer vibro sifter handles multiple materials at the same time, it is necessary to pay attention to the feeding.

4、The price is different

The multi-layer vibro sifter will use more material than the single vibro sifter, so the price will be more expensive, in general, the price will be 100-200 US dollars higher. So its single layer is cheaper than multi-layer vibro sifter.

For more detailed information, please feel free to contact Dahan Machinery.

-

Removal of excessive contaminants and foreign bodies in powders, particles and liquids

-

Made of 304 stainless steel, the inside and outside of the screen is polished, making it cleaner and sanitary.

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.