Single Vibro Sifter

![[field:title/]](/uploads/211116/1-2111161022144Z.jpg)

Callback

| Number of layers: | 1 layer and 2 discharge ports |

| Screen size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

Remove a single impurity in the material

The screen size can be arbitrarily configured

The whole machine has good sealing performance, the powder does not fly, and the liquid does not leak

Introduction of single vibro sifter

Single vibro sifter, also called single-layer vibro sifter, has two discharge ports, which can remove large particles and foreign bodies in powder, granules, and liquid materials. Single vibro sifter

According to the material, it is divided into carbon steel, 304 stainless steel and plastic material. Carbon steel single vibro sifter has no hygiene requirements and is cheap; 304 stainless steel single vibro sifter is used in food and pharmaceutical industries with high hygiene requirements. Plastic single vibro sifter is resistant to strong acid and alkali corrosion and is suitable for the chemical industry.

Working principle of single vibro sifter

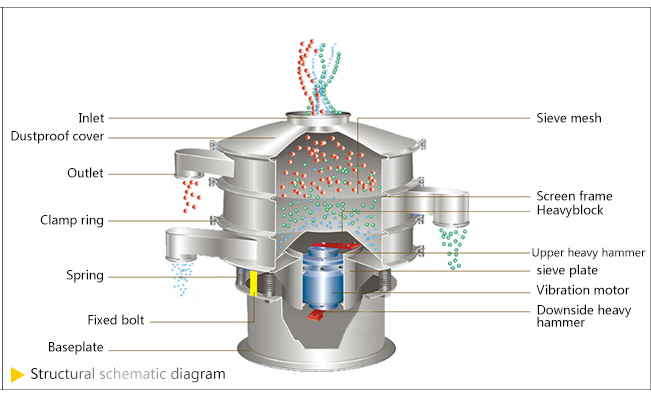

Single vibro sifter uses a vertical vibration motor as the excitation source, and the rotary motion is transformed into horizontal, vertical and inclined three-dimensional motion through the eccentric weights at the upper and lower ends of the vibration motor, and is transmitted to the screen surface of the single vibro sifter; the material passes through The feeding port enters the equipment. According to different screening requirements, the material passes through 2 layers of sieves with different meshes. The material can be screened smoothly and effectively avoid the problem of material blocking. The materials with different meshes are discharged through the corresponding meshes of each layer or through the discharge port set at each layer, and finally realize the impurity removal of the material. and filtering. Adjusting the phase angle of the upper and lower ends of the motor can change the movement track of the material on the screen surface.

Featured videos

-

Remove lumps and foreign matter in soybean flour

-

Filter the impurities in the lime milk

Benefits of single vibro sifter

1. There are only two discharge ports on the top and bottom, and the finished material can be divided into two different specifications, with a classification accuracy of more than 95%.

2. The sieving fineness reaches 500 meshes (28μm), and the filtration fineness reaches 5μm.

3. Impurities and coarse materials are automatically discharged, and continuous operation is possible.

4. The fully enclosed structure can ensure that the material is free of dust during screening.

Structure of single vibro sifter

Single vibro sifter consists of vertical vibration motor, bottom barrel, vibrating disc, screen frame, beam ring, screen mesh, punching plate, net cleaning device, upper cover, feed port, discharge port and so on.

Vibration motor: As a power supply component, a vertical vibration motor is used, and the motor power can be freely selected from 0.18KW to 4.0KW (the larger the diameter of the equipment, the greater the motor power used). For some special industries, explosion-proof vibration motors can be equipped.

Bottom barrel: This part plays the role of supporting the screen body and bearing the vibration motor. The thickness of the plate is 3mm~6mm, and the thickness is also determined according to the diameter of the equipment.

Vibration plate: This part plays the role of fixing the vibration motor and connecting the screen body. The plate used is Q235 carbon steel with a thickness of 4mm~6mm.

Screen frame: This part is used to restrain the material and make the material produced within a certain range. The common materials are Q235 carbon steel and 304 stainless steel, and the material thickness is 2.0mm~3.0mm.

Beam ring: This part plays the role of connecting the bottom cone and the screen frame, the upper and lower screen frames, and also plays the role of preventing material leakage.

Screen: The parts that are in direct contact with the material play a role in improving the screening accuracy and product quality. The commonly used material is 304 stainless steel woven mesh.

Punching plate: This part is used to lift the screen and prolong the service life of the screen. The commonly used material is 304 stainless steel.

Cleaning device: There are three kinds of cleaning devices: bouncing ball, ultrasonic wave, and rotating brush. Users can choose reasonably according to different production processes.

Upper cover: It acts as a seal and can effectively dissipate dust.

Outlet: There are 2 outlets for discharging coarse material and fine material respectively.

Technical parameters of single vibro sifter

The above models are all single-layer, and can be made in multiple layers according to customer needs, up to 5 layers

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Application of single vibro sifter

Single vibro sifter is mostly used for materials that have less impurities and are easy to pass through the net, such as: bean dregs, fruit juice, soy milk, yeast, pineapple juice, fish meal, food additives, etc.

Food industry: starch, powdered sugar, coffee powder, glutinous rice flour, soybeans, corn, peanuts, sesame, soy milk, vinegar, etc.

Pharmaceutical industry: Chinese medicine powder, medicine, vitamins, etc.

Chemical industry: paint, washing powder, paint, soda ash, lemon powder, resin powder, plastics, etc.

Abrasives, ceramics industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, special electrode powder, etc.

Papermaking industry: coating paint, clay slurry, black and white liquid, waste liquid, papermaking liquid, etc.

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Medicine powder | 0.8 | 80 | DH-800-1S | 550㎏ | |

| Iron powder | 3 | 400 | DH-800-1S | 230㎏ | |

| Mica | 0.8 | 200 | DH-800-1S | 110㎏ | |

| Waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000IT |

Related cases

-

Used for screening, classifying and removing impurities in various powder ...

-

Granules, powders, and paddle materials can be used ...

-

Made of 304 stainless steel, the inside and outside of the screen ...

-

Difference between single vibro sifter and multi-layer vibro sifter

vibro sifter is divided into single vibro sifter and multi-layer vibro sifter according to the screeni ...

-

Circular sieve manufacturers

Because there are demand, there are many manufacturers of circular sieves on the market. Where are th ...

-

Where is the powder sieve purchased?

Whether it is a small DH-400, an hourly output of 1 ton, or a large one such as DH-2000...

-

Which manufacturer's powder sieving machine is better?

The powder industry chooses to use a vibrating screen for screening ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.