How to reduce the loss of metal powder sieving machine screen?

The loss of the screen of the metal powder sieving machine is very troublesome, so do you know how to reduce the loss of the screen of the metal powder sieving machine?

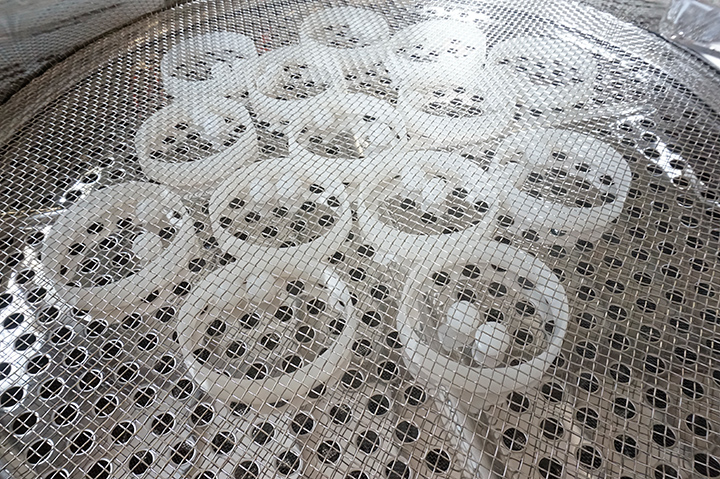

1. Choose good quality metal powder sieving machine screen

The quality of the metal powder sieving machine screen directly determines the service life of the screen. Many people buy poor quality screens in order to save some money. After using the screen for a long time, the screen will be damaged and damaged. Continue to replace the screen, from the frequency and quantity of replacement, the actual difference of the screen is not saving money, there is a certain reason for the price of the goods.

⒉.Metal powder sieving machine screen installation problem

The installation of Metal powder sieving machine needs to be tightened on the mesh frame. If the tension of the screen is not enough, there will be vibration during the screening operation of the vibrating screen. The edge of the screen frequently reciprocates, and the metal is easily fatigued. There is a problem of breakage on the edge of the screen or the edge of the wrapping bead.

3. The feeding problem of Metal powder sieving machine

The metal powder sieving machine is a continuous operation equipment, so the vibrating screen equipment needs to be given continuous feeding. If too much material is fed at one time, the material will accumulate on the vibrating screen screen, which will cause the vibrating screen to become fatigued and loose in the morning. , reducing the screening efficiency, and the equipment itself also has the damage of the vibration motor caused by the increase in the workload, so it is very important to evenly feed the vibrating screen.

-

Ensure accurate particle size of metal powder and remove excessive contaminants

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.