Metal Powder Sieving Machine

Callback

| Screen size: | 80-600 mesh |

| Capacity: | 100-5000kg/h |

| Number of layers: | 1-5 layers |

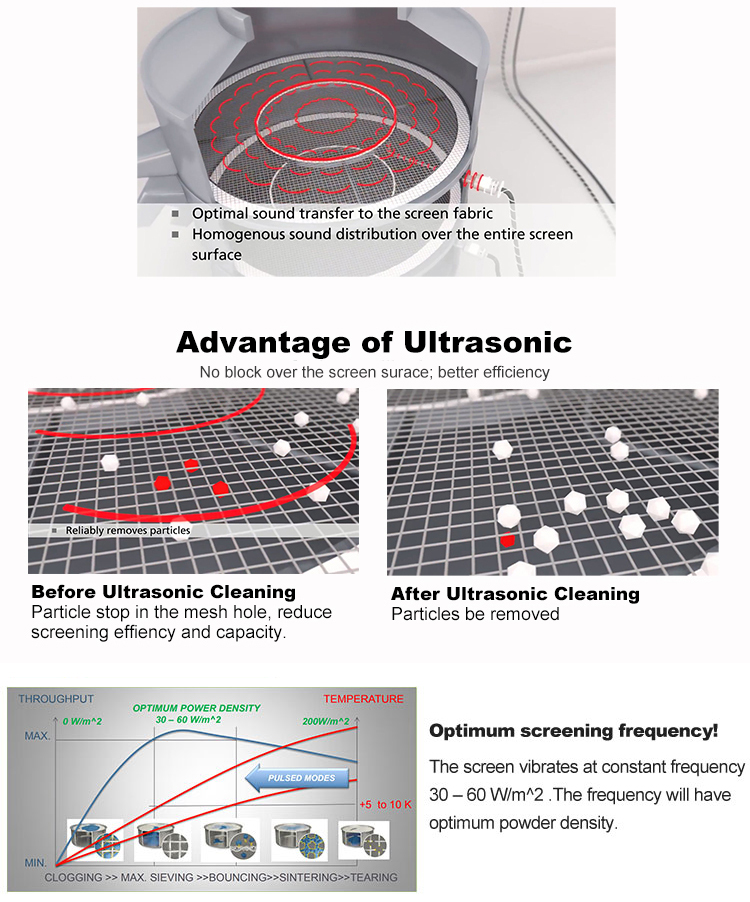

Combined with an ultrasonic deblinding system, metal powders down to 20 microns can be precisely sieved

Vacuum closed screening, no dust will be generated

The sieving process is carried out in a chemically inert gas to prevent oxidation of the metal powder

What is a metal powder sieving machine?

In the production of metal powder processing, the powder must be sieved after reduction and grinding. Because powder sieving can not only remove unground oversized particles or agglomerates, but also ensure uniform particle size of metal powder. Powder metallurgy also relies on sieving after sintering and pressing to ensure product quality before entering the next production process. The metal powder sieving machine sends ultrasonic waves to the surface of the sieve to prevent clogging or damage of the sieve, greatly increasing the sieving rate, and can very accurately sieve metal powder with a size of 40 μm, achieving a purity of more than 99% and a recovery of 92%.

Metal powder sieving machine can be equipped with ultrasonic deblinding system and inert gas protection system to avoid the adsorption of fine powder and reduce the probability of screen blockage. In addition, fine metal powder is more easily oxidized when exposed to the air, especially in the metal 3D printing industry. High-end metal powder, this product can be added with an inert gas protection system during the screening process, and the oxygen content of the system is automatically controlled throughout the process to prevent the metal powder from contacting the air and ensure the purity of the powder.

What is the purpose of metal powder sieving machine?

Metal powder sieving machine can produce the finest quality metal powders (e.g. for additive manufacturing) or process them for reuse and separate agglomerates or dust, designed to revolutionize your metal powder recycling process, methods Using a vacuum to extract powder from the print bed, then sieving the powder for future use, the used powder can be recovered and reconditioned to a precise particle size, reducing waste and operating costs while preventing contamination of the product and factory environment.

Screening materials: Metal powders in the following range can be screened, coarse powder (>150μm), medium particle size powder (44~150μm), fine powder (10~44μm), fine powder (0.5~10μm), ultrafine powder ( ≤ 0.5μm), such as iron powder, tungsten carbide, alumina, graphite powder, stainless steel powder, aluminum powder, lead powder, magnesium powder, nickel powder, silicon carbide, etc.

Types of metal powder sieving machines

Industrial powder sieving machine (vibrating screen)

Working principle: Use vibration force to screen metal powder

Applicable scope: 100-500 mesh metal powder, such as iron powder, copper powder, stainless steel powder, etc.

Advantages: Suitable for mass production, with ultrasonic system, suitable for ultra-fine powder

Drum screening machine

Working principle: Metal powder is graded and screened through a rotating drum

Scope of application: 40-200 mesh metal powder, such as welding powder, aluminum powder, iron powder, etc.

Advantages: Suitable for large particle materials, large processing capacity, suitable for continuous production

Airflow screening machine (suitable for ultra-fine metal powder)

Working principle: Separate lightweight and ultra-fine metal powders through air flow

Scope of application: 300-600 mesh metal powders, such as silver powder, conductive copper powder, ultra-fine aluminum powder, etc.

Advantages: Prevent powder agglomeration, suitable for high-precision powder screening, such as electronic materials, 3D printing powder

Inline screen (suitable for fast screening)

Working principle: the material flows in a straight line, screens quickly, and reduces the retention time

Scope of application: 60-300 mesh metal powder, such as zinc powder, titanium powder, iron powder, etc.

Advantages: suitable for mass production

Swinging screen (suitable for high-precision screening)

Working principle: Screening is achieved by reciprocating swinging motion, suitable for powders with high precision requirements

Scope of application: 80-400 mesh metal powders, such as high-purity copper powder, nickel powder, tungsten powder, etc.

Advantages: High screening accuracy, more uniform particles can be screened, suitable for difficult-to-screen materials, such as sticky metal powders

How it works of metal powder sieving machine

Process flow of metal powder conveying and screening system: material truck/barrel—negative pressure conveying—buffering—screening—packaging.

The metal powder is loaded into the airtight material barrel in advance, and the valve under the material barrel can control the passing speed of the powder, and the powder enters the vibrating feeder below through its own weight, and the vibrating feeder conveys the material evenly to the metal powder sieving machine through vibration , the metal powder sieving machine sieve generates a three-dimensional motion through a vibrating motor, forcing the material to jump and roll on a certain track on the sieve. The ultrasonic blockage system can disperse the electrostatic clumping and sticky powder, speed up the mesh passing efficiency and prevent When the screen is blocked, the smaller powder falls through the screen, and is discharged from the lower outlet through the silicone soft connection into the airtight buffer barrel for standby, while the larger powder moves on the screen with a certain trajectory and flows from the upper layer. The material is discharged from the outlet and enters the airtight buffer barrel through the silicone soft connection to complete the screening operation. Considering that some metals need to be protected by adding inert gas during the screening process, the equipment has reserved air inlets and exhaust outlets.

Featured videos

-

Metal powder sieving machine for molybdenum powder

-

Metal powder sieving machine for alumina powder

Recommended metal powder sieving mesh size

Coarse-grained metal powder (40-100 mesh): Suitable for applications requiring larger particles such as powder metallurgy and welding materials.

Medium-grained metal powder (100-300 mesh): Widely used in applications such as coatings, conductive materials, and 3D printing.

Ultrafine metal powder (300-600 mesh): Suitable for high-precision applications such as conductive inks, electronic pastes, and high-end 3D printing.

What are the advantages of metal powder sieving machines?

1. A major challenge when sifting powder metal is preventing the screen from becoming clogged with extremely fine particles, as cleaning and maintenance can lead to loss of high-value metal powder and production downtime. The Metal powder sieving machine uses an acoustically developed transducer to apply high frequency vibrations to the screen and prevent oversized and undersized particles from clogging or clogging the screen, allowing sieving on finer meshes (down to 20 microns).

2. A gas protection device is installed on the basis of the metal powder screening machine, which can be filled with inert gas as required to isolate the material from oxygen and prevent oxidation reaction.

3. The closed system can be purged with inert gas to isolate contamination-sensitive powders from ambient air and moisture, reducing cross-contamination of powders, eliminating operators having to touch powders, and ensuring a safer environment.

4. The hygienic stainless steel structure eliminates dead spots, allowing complete evacuation and easy cleaning.

Technical parameters of metal powder sieving machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases of metal powder sieving machine

| Materials | Proportion | Mesh Size | Model | Method | Capacity (kg/h) |

| Graphite powder | 1.2 | 16/40/80 | DH-1000-3S | Dry | 1400㎏ |

| Lead powder | 11.34 | 10/80 | DH-1000-2S | 1000㎏ | |

| Tungsten carbide powder | 7.5-9.0 | 20-60 | DH-800-2S | 400㎏ | |

| Gold copper powder | 2 | 100 | DH-800-1S | 70㎏ | |

| Iron powder | 3 | 400 | DH-800-1S | 230㎏ | |

| Aluminum powder | 0.9/1.2 | 80/120 | DH-800-2S | 350㎏ | |

| Electrode powder | 0.95 | 20/200 | DH-1000-2S | 550㎏ | |

| Titanium dioxide | 2.1 | 16 | DH-800-1S | 600㎏ | |

| Manganese dioxide | 2 | 60 | DH-1000-1S | 1550㎏ | |

| Electrolytic copper powder | 1.5/2.4 | 24 | DH-1000-1S | 210㎏ |

Mesh size recommendations for different metal powders

| Metal | Common particle size | Recommended mesh | Application |

| Iron powder | 50-500μm | 50-100 mesh | Powder metallurgy, magnetic materials |

| Copper powder | 10-200μm | 80-150 mesh | Conductive coating, electronics industry |

| Aluminum powder | 20-300μm | 60-120 mesh | Spraying, light alloy |

| Titanium powder | 10-150μm | 100-200 mesh | 3D printing, aerospace |

| Silver powder | 1-50μm | 200-400 mesh | Electronic slurry, conductive film |

| Tungsten powder | 10-100μm | 100-150 mesh | Hard alloy, thermal spraying |

Why choose us

Xinxiang Dahan metal powder sieving machine manufacturer has a variety of standard models, ranging from 400mm to 1800mm in diameter, it is equipped with a gas protection device and an ultrasonic deblinding system to ensure that the metal powder will not block the grid and oxidize, we have 15 years of experience. Experience in manufacturing high-quality screens and filters in multiple process industries can provide you with custom solutions to meet your unique requirements.

-

Designed for high volume screening of powders to remove oversized contamination

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers, and 6 different grades of graphite powder can be obtained in one operation.

-

Metal Powder Sieving Machine for trash removal! Metal powder coarse and fine classification screening machine!

Metal powder sieving machine refers to the group of metal particles whose size is less than 1mm ...

-

metal powder sieving machine price

After choosing the model of the metal powder sieving machine for the customer, its price ...

-

How to reduce the loss of metal powder sieving machine screen?

The loss of the screen of the metal powder sieving machine is very troublesome, so do you ...

-

metal powder sieving machine solution use

After choosing the model of the metal powder sieving machine for the customer, its price ...

E-mail:

sale@xxdahan.com

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.