Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials. In order to improve the quality and stability of coatings, coating manufacturers are increasingly using vibrating screens with coating raw material screens as important screening equipment.

Coarse particle size screening:

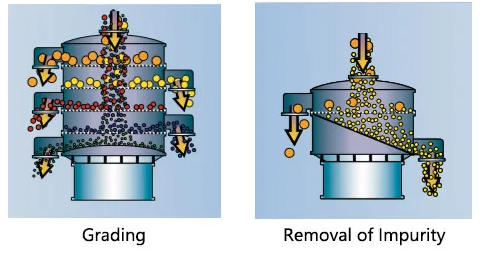

Paint raw material screening belt vibrating screen can screen coarse particles in paint raw materials. Through the high-frequency vibration of the vibrating screen, larger particles will be moved up and down the screen, while fine particles will fall through the screen holes. This can remove oversized particles in the raw materials and ensure the uniformity and fluidity of the coating raw materials. Coarse particle level screening can improve the quality of the paint and avoid affecting the use effect of the paint due to excessive particles.

Medium particle size screening:

The paint raw material screening belt vibrating screen can also screen the medium particles in the paint raw materials. The medium particle size is screened to ensure coating properties and gloss. Through reasonable screen design and vibration force, the vibrating screen can screen out medium-sized particles, making them more even when mixed with other formula raw materials, improving the coating effect and gloss of the paint.

Fine particle size screening:

Paint raw material screening belt vibrating screens also play an important role in screening fine particle grades. The screening of fine particles is critical to the stability and quality of coatings. The paint raw material screen belt vibrating screen can customize the fine mesh size according to the needs of paint production, and screen out the particles that are too small to ensure the uniformity and stability of the paint. Fine particle level screening can avoid particle accumulation and agglomeration, improving the fluidity and coating effect of paint.

Paint raw materials sieve with vibro shaker Advantages:

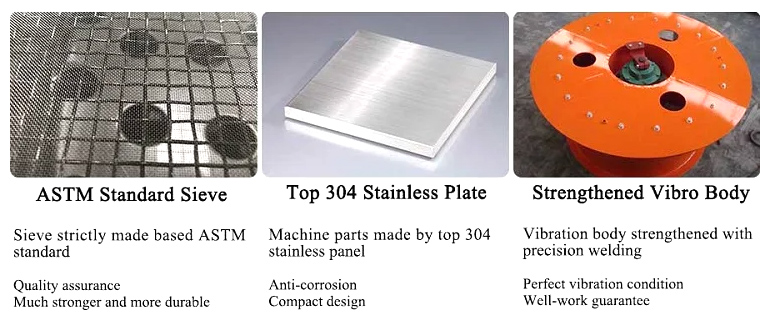

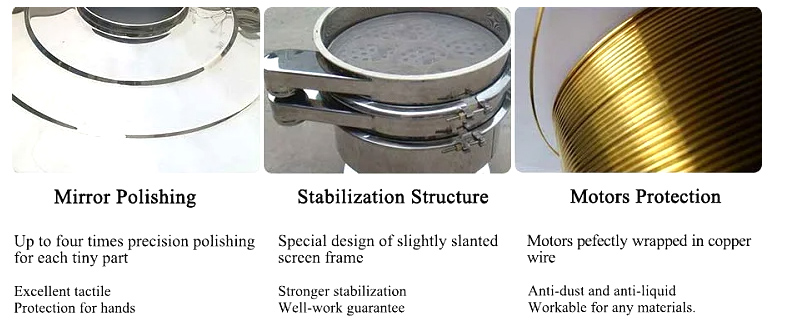

Paint raw materials sieve with vibro shaker has significant advantages in the classification and screening of paint raw materials:

Efficient screening: The paint raw material screening belt vibrating screen uses high-frequency vibration, which can quickly and effectively screen raw materials and improve screening efficiency.

Precise grading: The mesh size of the vibrating screen can be customized according to the needs of paint production to achieve precise grading of raw materials.

Improve paint quality: Through screening of coarse, medium and fine particle levels, ensure the uniformity, fluidity and stability of paint raw materials and improve the quality of paint.

Energy saving: The paint raw material screening belt vibrating screen is driven by a vibration motor, which can save more energy than traditional rotating screening equipment.

Environmental protection and low noise: The noise generated during the working process of the vibrating screen is relatively low, reducing the impact on the working environment and operators.

Paint raw materials sieve with vibro shaker Application:

Paint raw materials sieve with vibro shaker is widely used in paint production to screen different grades of paint raw materials. It can be used to screen various coating raw materials, such as pigments, fillers, resins, etc. Through precise screening of raw materials, impurities and overly large or small particles can be removed, improving the purity and uniformity of raw materials. At the same time, the screened raw materials can be better mixed with other formula raw materials to ensure the stability and consistency of the coating.

Paint raw materials sieve with vibro shaker As a grading and screening equipment in paint production, with its efficient and precise screening capabilities, it has become a powerful tool to improve the quality of paint. Different levels of screening can ensure the uniformity, fluidity and stability of paint raw materials, and improve the quality and coating effect of paint.

-

Removes all oversized contamination or agglomerates from powder ...

-

One of precised powder sieve,suitable for any particle, po ...

-

Dietary Supplements for Vibrating Sieve

Dietary supplements vibrating sieve As an efficient and reliable sieving equipment, it plays an important role in the production of dietary supplements. Through high-frequency vibra ...

-

Aqua Feed For Ultrasonic Vibrating Screen

The aquatic feed ultrasonic vibrating screen uses advanced ultrasonic technology to achieve an efficient screening process through high-frequency weak vibration. Compared with tradi ...

-

Garnet for Powder Sieving Machine

The powder sieving machine can be used to control the particle size of garnet powder, remove impurities and uniformly disperse it to meet the needs of different industries....

-

Alabaster for Powder Sieving Machine

Alabaster powder sifting machine is a gypsum powder handling equipment specially designed to meet customer needs....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.