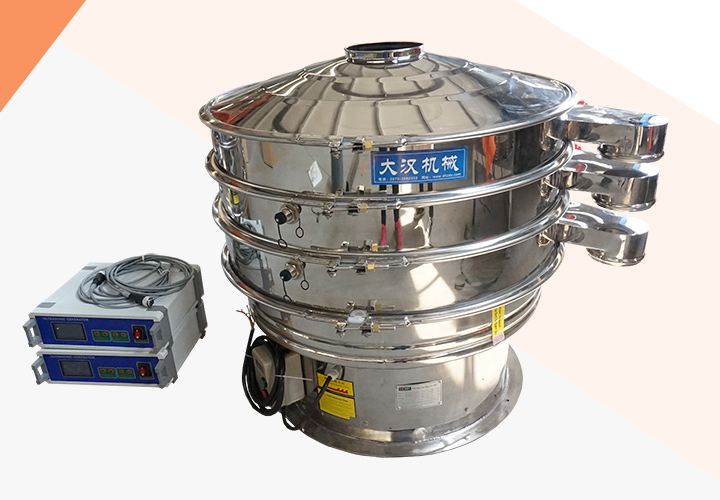

Powder Coating Ultrasonic Sieving Machine

![[field:title/]](/uploads/220729/1-220H914563SY.jpg)

Callback

| Screen size: | 80-900 mesh |

| Output: | 100-5000kg/h |

More than 500 mesh screening, no mesh blockage, no screening efficiency attenuation.

While achieving high-precision, high-mesh sieving, it can control a narrow particle size range.

Powder coating ultrasonic sieving machine sieving system consists of ultrasonic resonance power source, transducer and resonance ring. The high-frequency electrical oscillations generated by the ultrasonic resonant power supply are converted into longitudinal oscillation waves in the form of high-frequency sinusoids by the oscillator. These oscillation waves are transmitted to the resonant ring to resonate the resonant ring, and then the resonant ring transmits the vibration evenly to the screen surface.

Features of Powder coating ultrasonic sieving machine:

1. While achieving high-precision and high-mesh sieving, it can control a narrow particle size range.

2. It can be used in single-layer and multi-layer, and a set of intelligent ultrasonic generator uses three transducers at the same time.

3. Complete self-cleaning function of the screen mesh: more than 500 mesh screening, no mesh blockage, no screening efficiency attenuation.

4. Really solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity.

5. Ensure that the characteristics of the processed materials remain unchanged.

6. The screening accuracy can be increased by 1-100%, and the output can be increased by 1-10 times.

Compared with ordinary vibrating screen, the advantages of Powder coating ultrasonic sieving machine are as follows:

1. Ultrasonic vibrating screen realizes high-efficiency screening and high-precision screening, the accuracy is as high as 95% or more, and the output can be increased by 2-10 times.

2. It can effectively prevent the mesh holes from being blocked, so that the screening particle size range is wider, extending to 0.02mm, so that the materials that cannot be screened by ordinary machines can be screened.

3. It is a real solution to the screening of materials with strong adsorption, agglomeration, easy generation of static electricity and light specific gravity.

4. Ultrasonic digital control system, precise, stable and reliable.

5.24 hours of continuous work without cooling treatment, leading the industry.

6. The transducer can be built-in or external, and the external transducer makes liquid filtration feasible.

7. Transducer screw connection, easy to clean, and disassemble.

8. It can screen materials within 20 microns and liquids within 10 microns.

9. There is no need for aprons to clean the net to avoid secondary pollution of materials caused by rubber ball wear.

10. Special ultrasonic grid structure, no pollution, no dead angle, uniform force.

How to use Powder coating ultrasonic sieving machine:

| materials | Screen (mesh) | Yield (kg/h) | Screen diameter (mm) | |

| Ordinary vibrating screen | Ultrasonic vibrating screen | |||

| Pigment powder | 100 | 190 | 900 | Φ1000 |

| 150 | 97 | 450 | Φ600 | |

| 200 | - | 270 | Φ600 | |

1. According to the logo of the ultrasonic generator connecting line, directly insert the interface and lock it, so that the power supply of the ultrasonic generator and the ultrasonic interface of the sieve machine are correctly connected.

2. Turn the fine-tuning knob on the power supply of the ultrasonic generator to the minimum, turn on the power switch of the ultrasonic generator, and check whether the ammeter is abnormal (under normal circumstances, the current should be less than 200mA).

3. Check and debug the three-dimensional vibrating screening filter, and make the material running track reach the standard running track.

4. Run the three-dimensional vibrating screening filter (vibrating screen), put in a little material and fine-tune the knob on the power supply of the ultrasonic generator to make the screen reach an ideal state. (The current should be less than 200mA)

5. Under the normal condition of the ultrasonic vibrating screen, the material can be uniformly fed and then put into normal operation.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.