Quartz Sand Vibro Sifter

![[field:title/]](/uploads/211125/1-211125102T5256.jpg)

Callback

| Screening particle size: | 0.5mm-32mm |

| Capacity: 5000kg/h | Layers: 1-5 |

No mixing, no stringing

Impurities and coarse materials are automatically discharged, and continuous operation is possible.

Screening accuracy>90%

Introduction of quartz sand vibro sifter

The coarsely processed quartz sand of 1-0.5mm and 0.5-0.1mm grades can be vibrated and ground by a vibrating mill/vibrating rod mill. After grinding, it can be sieved with quartz sand vibro sifter to prepare about 100-300 mesh. Refined powder; if you want to achieve finer grinding, a high-efficiency Raymond mill is generally used for grinding, and there is no need to sieve the powder after the powder. 500 mesh finished product.

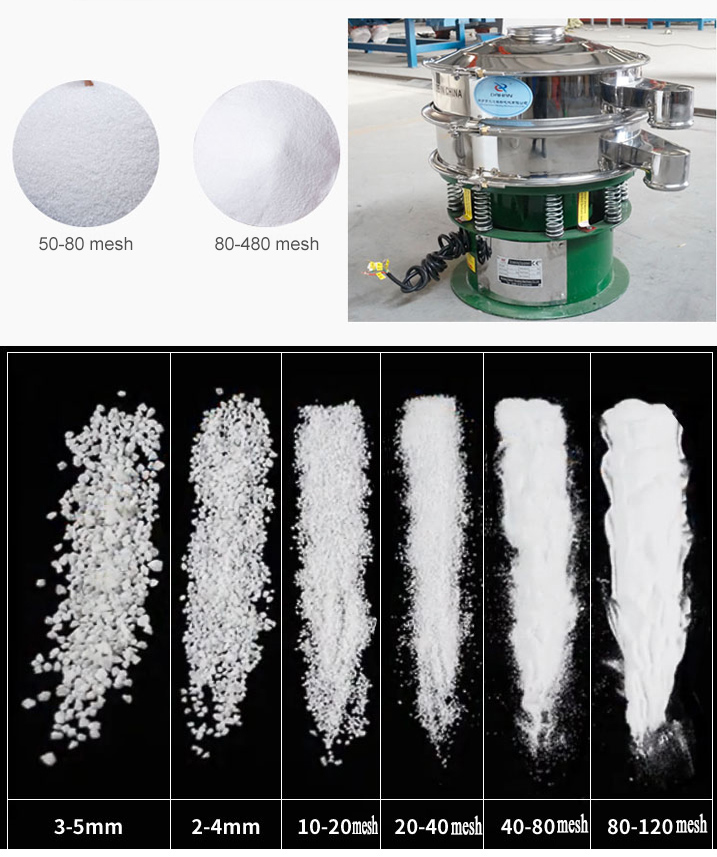

The finished coarse materials generally have 4 meshes, 8 meshes, 16 meshes, 30 meshes, 50 meshes, 80 meshes, 100 meshes, 140 meshes, and the screening accuracy is more than 90%. pink.

Classification process of quartz sand

The quartz sand is initially crushed by the coarse crusher, and the coarse material produced is transported by the belt conveyor to the fine crusher for further crushing. The finely crushed quartz sand enters the quartz sand vibro sifter to screen out two kinds of stones, which meet the feeding requirements of the sand making machine. Quartz sand with particle size is used as sand-made sand, and another part of the returned material is used for fine crushing. Part of the stones in the sand feeding machine is made into sand, which is cleaned by the sand washing machine to make finished sand, and the other part is broken again by the sand feeding machine.

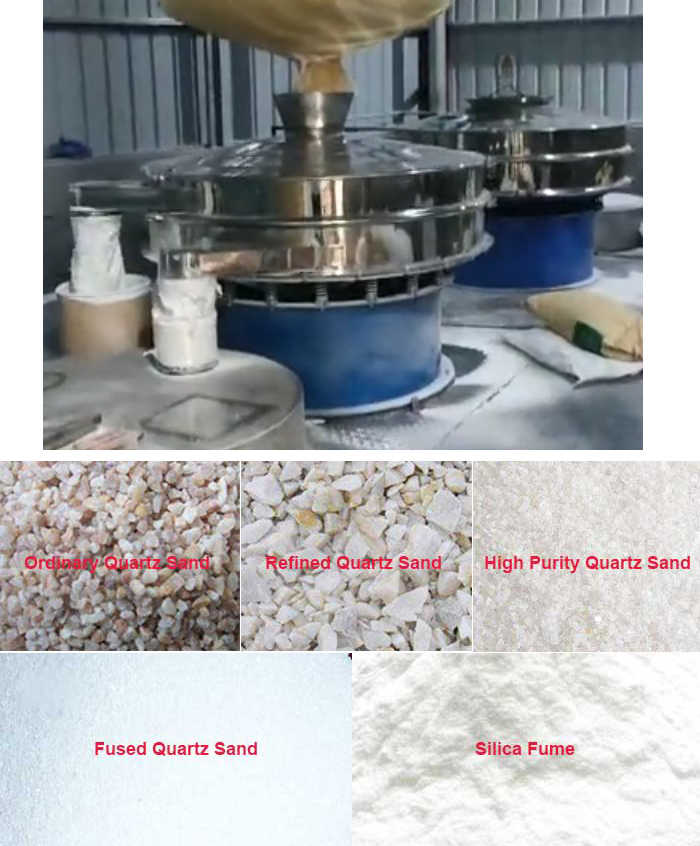

Application of quartz sand vibro sifter

Quartz sand vibro sifter is used for the screening and classification of quartz sand. Since the particle size of quartz sand is different, the common specifications are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16- 32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-120 mesh, the following is the application of different quartz sand.

1. Refined quartz sand

Refined quartz sand, also known as pickling quartz sand, is made of high-quality ore for complex processing. The particle size range is 5-480 mesh, which can be produced according to user requirements, and the appearance is white or crystalline. Main uses: high-grade glass, glass products, refractory materials, smelting stones, precision casting, grinding wheel abrasives, etc. (mm is bom)

2. Fused silica sand

The appearance is colorless and transparent block, granule or white powder, so in order to make quartz sand be well used in various fields, it is necessary to screen and classify quartz sand, so quartz sand vibro sifter will be used.

3. High-purity quartz sand

It is made of 1-3 grade natural crystal stones and high-quality natural stones, which are carefully selected and finely processed. The particle size range is 1—0.5mm, 0.5—0.1mm, 0.1—0.01mm, 0.01—0.005mm, and can be produced according to user requirements. (mm is bom)

4. Ordinary quartz sand

The refractoriness is 1750℃, the appearance part is large particles, and there are yellow skin cysts on the surface. The particle size range is 5-220 mesh, which can be produced according to user requirements. Main uses: metallurgy, ink silicon carbide, glass and glass products, enamel, cast steel, water filtration, caustic soda, chemical industry, spray noise and other industries.

| Sand Types | SiO2 | Fe2O3 | Particle Size | Application |

| Ordinary Quartz Sand | ≥90-99% | ≤0.06-0.02% | 0.075-4mm | Metallurgy, graphite silicon carbide and glass products |

| Refined Quartz Sand | ≥99-99.5% | ≤0.005% | 0.005-1mm | Refractories, smelting ferrosilicon, metallurgical flux, ceramics, abrasives |

| H-Purity Quartz Sand | ≥99.5-99.9% | ≤0.001% | 0.005-1mm | Construction, chemical industry, plastic, rubber |

| Fused Quartz Sand | 99.9-99.95% | 5PPM-25PPM | 0.075-5mm | Important filter materials for water plant drainage and sewage treatment |

| Fused Quartz Sand | 75-96% | 0.9±0.3% | 0.0048-0.045mm | Electronics, integrated circuits, plastics, coatings, rubber |

Featured Videos

Benefits of quartz sand vibro sifter

1. The finished coarse materials generally have 4 mesh, 8 mesh, 16 mesh, 30 mesh, 50 mesh, 80 mesh, 100 mesh, 140 mesh, and the screening accuracy is more than 90%.

2. 1-5 layers, 6 kinds of quartz sand with different particle size specifications can be obtained in one operation.

3. Using high-efficiency cleaning device systems such as silicone rubber balls and ultrasonic waves, the sieve holes will not be blocked.

4. Sealed design to prevent dust pollution.

Working principle of quartz sand vibro sifter

After the quartz sand is processed, the quartz sand vibro sifter should be used for grading and impurity removal. The working principle of the quartz sand vibrating screen uses a vertical vibration motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to rotate the motor. The movement is transformed into a horizontal, vertical, and inclined three-dimensional movement, and then this movement is transmitted to the screen surface for screening. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Technical parameters of quartz sand vibro sifter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of quartz sand vibro sifter

Quartz sand vibro sifter can be classified in multiple layers, and different particle sizes have different uses. The finished coarse materials generally have 4 mesh, 8 mesh, 16 mesh, 30 mesh, 50 mesh, 80 mesh, 100 mesh, 140 mesh, and the same specification particles are required. The degree is uniform and tidy, and does not contain large particles and fine powder.

Customer site

-

Used for screening, classifying and removing impurities in various powder ...

-

Granules, powders, and paddle materials can be used ...

-

Made of 304 stainless steel, the inside and outside of the screen is polished ...

-

Taking quartz sand vibro sifter as an example to describe the principle and case analysis of quartz sand screening

Quartz sand vibro sifter is a special vibrating screen for quartz sand designed for grading various types ...

-

Application of quartz sand vibro sifter production process

The main equipment for producing quartz sand by dry method includes quartz sand vibro sifter , stone ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision ...

E-mail:

sale@xxdahan.com

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.