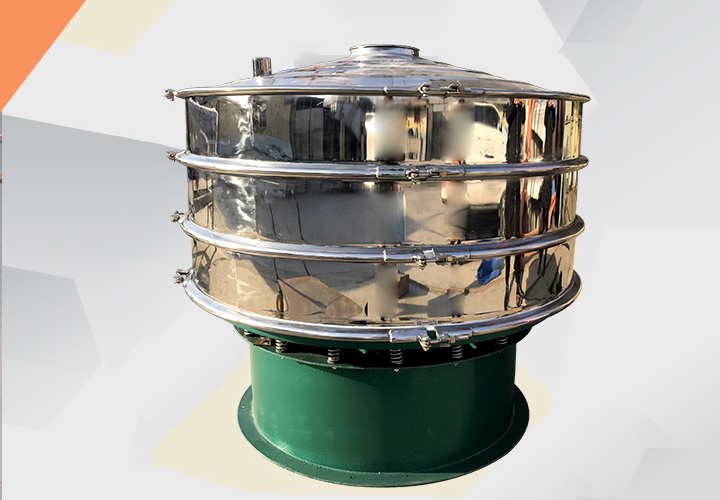

Sugar Mill Vibro Sifter

Callback

| Mesh size: | 2-500 mesh (10mm-0.025mm) |

| Capacity: | 100-3300Kg/hr |

| Material Grade: | SUS304 |

Quick cleaning system to prevent small and oversized particles from sticking to the screen

304 stainless steel material, surface materials can be contaminated

There are 4 levels of refined sugar dust, superior grade, first grade and second grade

Introduction of sugar mill vibro sifter

Sugar mill vibro sifter is used to remove impurities in sugar, remove agglomerations and foreign bodies in materials, and can also classify sugar. The common grades of sugar are: coarse grains (0.8-2.5mm), large grains (0.63-1.6mm) ), medium-grain (0.45-1.25mm), fine-grain (0.28-0.8mm), sugar mill vibro sifter treated sugar crystals are uniform, the crystals or its aqueous solution are sweet and have no peculiar smell.

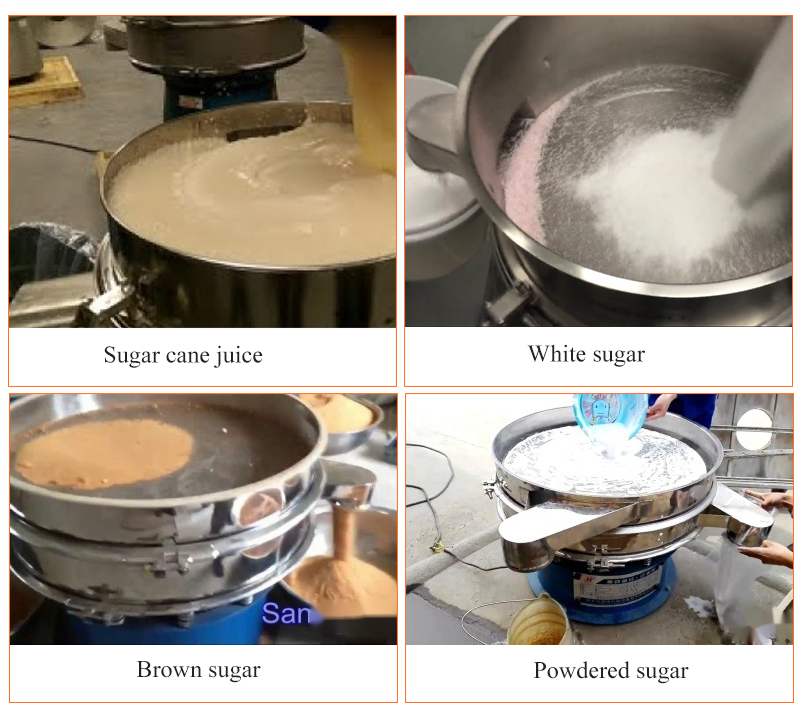

Application of sugar mill vibro sifter

1. In terms of raw material processing, taking sugarcane as an example, raw sugarcane harvested by mechanization generally has disadvantages such as poor quality and high impurity content. Excessively high impurity content in sugarcane has a great impact on the production cost of sugar factories, which will not only reduce sugar content , and debris such as sand and gravel will accelerate the wear and tear of sugar making equipment, so it is necessary to use sugar mill vibro sifter for basic impurity removal.

2. The mixed juice made by crushing and pressing of raw materials contains a lot of bagasse and cane bran. If it is not separated, it will not only block the pipeline and equipment of the white sugar production line, but also the pigment contained in these impurities will increase the sugar juice The color value reduces the purity, so a special sugar mill vibro sifter must be used to filter the mixed juice to remove impurities. The traditional press construction uses a primary curved sieve or a secondary screening equipment composed of a copper bar trommel and a curved sieve. However, with the improvement of the crushing capacity of the modern sugar industry, this equipment can no longer meet the production requirements, and the backward separation equipment There are problems such as large space occupation and high operation failure rate, and now there is no sugar factory to use it.

3. Grading and screening the dried white granulated sugar. The white granulated sugar produced after a series of processing processes will inevitably contain a lot of lumps and powdered sugar when it comes out of the dryer, resulting in different grain sizes. In order to improve the quality of the product, the white granulated sugar must use sugar before packaging. The mill vibro sifter is used for grading, and at the same time, the dried product can have sufficient cooling time during the screening process, which is convenient for packaging and storage.

Working principle of sugar mill vibro sifter

Sugar mill vibro sifter uses a vertical vibration motor. The two ends of the motor shaft are equipped with eccentric blocks, and the upper and lower eccentric blocks form an angle. When the motor is running, the action of the box spring makes the whole box do The three movements are horizontal, vertical, and inclined. When in use, the material enters from the feed port. After receiving the force, it spreads around and then moves in a circular motion. The material smaller than the sieve hole passes through the screen and enters the next layer. The net material is discharged from the outlet after a week of movement.

Featured videos

-

Remove foreign matter in sugar

-

Remove all foreign particles in brown sugar

Benefits of sugar mill vibro sifter

1. Choose 304 stainless steel, so that the large particles and small powder in the white sugar can be well screened out under the condition of ensuring the hygienic requirements, and the purity and quality of the white sugar can be improved.

2. Equipped with 1-5 layers of screens, it can sort sugar into 2-6 different specifications.

3. The diameter ranges from 400mm to 2000mm, and its various models are suitable for customers with different production volumes, and the allowable production volume can reach 100-3300kg.

4. The fully enclosed structure can prevent material leakage or external dust from entering the machine, causing pollution to materials and the working environment.

5. The bouncing ball confined in the grid under the screen removes the particles stuck on the screen by directly hitting the screen, so that the surface of the screen is kept clean at all times, and the vibration generated by the impact is helpful for the separation of materials and the sticking together Separation of particles.

Technical parameters of sugar mill vibro sifter

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Coarse sugar | 1.2 | 12 | DH-1500-1S | Do | 8000㎏ |

| Powdered sugar | 0.5-0.8 | 100 | DH-800-1S | Do | 200㎏ |

| Glucose powder | 0.8 | 6、20 | DH-1200-2S | Do | 2000㎏ |

-

Used for screening, classifying and removing impurities in various powder ...

-

It can carry out 2-6 levels of screening and classification at the same time ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.