Tea Leaf Sieve Machine

![[field:title/]](/uploads/211125/1-21112515410G13.jpg)

Callback

| Mesh size: | 2-500 mesh (0.5-0.025mm) |

| Output: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

The part in contact with the material is made of stainless steel, which is clean and hygienic

Almost no tea impaction in the mesh

Fully enclosed structure to ensure that the tea will not be contaminated during the screening process

Introduction of tea leaf sieve machine

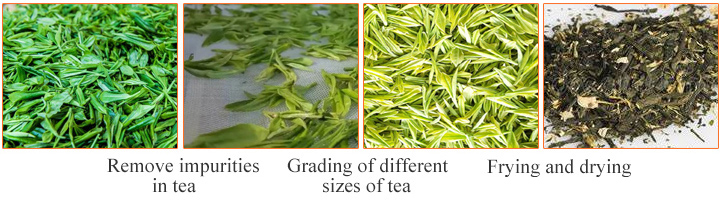

Tea leaf sieve machine, also called tea sorter machines, is a sorting machine that not only removes impurities in tea, but also screens uneven tea. It can classify teas of different prices according to grades, and automatically sort and discharge the materials, which is fast and efficient. The sieve effect is obvious. A tea leaf sieve machine can contain multiple sieves with different sieve apertures. Of course, you must choose the sieve model or the sieve shape according to the size of the tea. You can achieve 6 different gradation in a single operation as it can be structured up to 5 decks.

Application of tea leaf sieve machine

Tea leaves are divided into broken tea leaves and strip-shaped tea leaves according to the customer's sieving requirements. Broken tea leaves are generally used in tea triangle bags, and the purpose of sieving in either form is generally classified.

Broken tea leaves are generally sieved with 20 mesh/30 mesh/40 mesh/50 mesh/60 mesh.

Bar tea leaves are generally sieved with apertures of 10mm/8mm/6mm/4mm/2mm.

The purpose of the tea leaf sieve machine is to separate the tea leaves according to different grades, and also to sieve out the broken pieces in the tea, to meet the needs of different tea sieving all over the country.

| Mesh Size | Screening Purpose |

| 3mm | Screening small buds |

| 4mm | Screening pure buds |

| 5mm | Screening Hollow Sprouts |

| 6mm | Screening buds with buds |

| 8mm | Screening small buds and leaves |

| 10mm | Screening buds and leaves |

| 12mm | Separate tea leaves of different sizes |

Working principle of tea leaf sieve machine

Normally, the tea leaf sieve machine is a two-layer sieve. First, it is exhausted by a fan at the feed port to directly remove light-weight leaves or debris. The upper sieve is first sieved and then the large debris is cleaned. The tea leaves fall directly on the lower screen, the lower screen will leak out the small impurities in the tea, such as pebbles or defective tea leaves, and the intact tea will be sifted out from the discharge opening. This equipment solves the single function of manual picking, and can not effectively remove the defects of stones and soil blocks, and can bring satisfactory results for cleaning and cleaning tea. The equipment occupies a small area, is easy to move and operate, has reliable performance, and can be easily repaired. It has obvious dust and impurity removal efficiency, low energy consumption, and easy use. When ordering, you need to select the type according to the size standard of the finished tea and the size of the wire mesh.

Tea classification by linear vibrating screen (capacity 20t/h)

Featured Videos

-

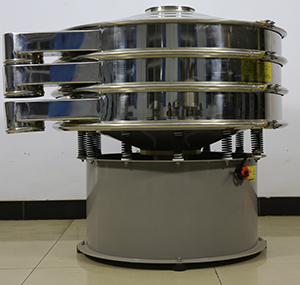

Round tea leaf sieve machine

-

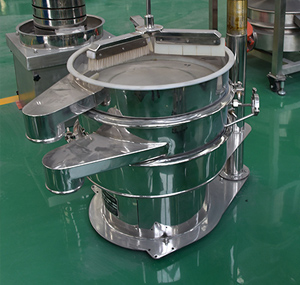

Linear tea leaf sieve machine

Technical parameters of tea leaf sieve machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Benefits of tea leaf sieve machine

1. It can select and remove impurities, secondary tea leaves with different lengths and shapes, and broken tea powder, etc., and the screening accuracy can reach more than 95%.

2. 1-5 layers of sieves can be selected, which can complete 2-6 grades of separation in one operation.

3. The discharge port can be adjusted arbitrarily at 360 degrees, which is convenient for the design and distribution of tea discharge, and it is also very easy to replace the screen.

4. Tool-free, quick-release mechanism facilitates disassembly and cleaning.

5. The compact form requires minimal headroom and can be easily integrated into your existing production line.

Related case

-

Perform sieving, filtration, impurity removal and impurity classification

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.