Tea Leaf Sifter Machine

![[field:title/]](/uploads/220215/1-2202151032502b.jpg)

Callback

| Yield: | 200-400 kg/h |

| Sieve mesh: | 2-10mm |

The part in contact with the material is made of stainless steel, which is clean and hygienic

Almost no tea impaction in the mesh

Fully enclosed structure to ensure that the tea will not be contaminated during the screening process

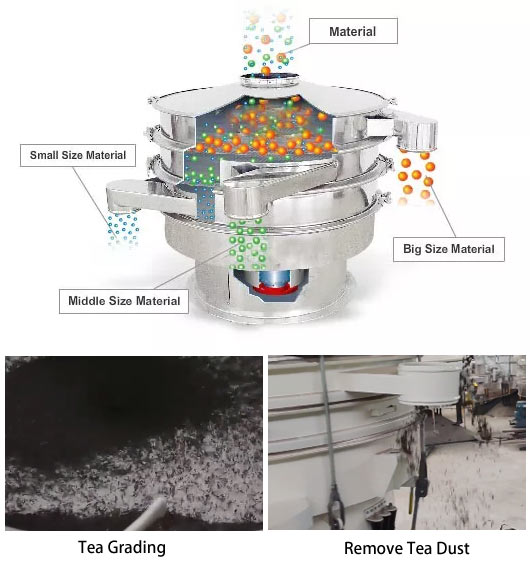

Tea leaf sifter machine can remove the thin tea stalks, tea foam and some sundries in the tea leaves, process the hair tea with complex shapes, different lengths and thicknesses, and spiral bends into commercial teas of various colors and grades according to different characters and qualities. Improve clarity, pure quality, and ensure hygiene. According to different processes, there are mainly 5 types: 10mm, 8mm, 6mm, 4mm, and 2mm.

Application of Tea Leaf Sifter Machine

Before the tea leaves are processed, the tea leaf sifter machine can effectively separate unwanted foreign matter and dust particles from the withered leaves, disperse the agglomerated tea leaves, screen and remove impurities and sub-tea, maintain the bright color of the tea leaves, and ensure Taste. Tea leaves go through a series of technological processes, and it is inevitable that there will be a lot of tea powder. The existence of the tea leaf sifter machine can efficiently sieve and separate the tea powder.

Mesh count of Tea Leaf Sifter Machine

Tea leaves are divided into broken tea leaves and bar-shaped tea leaves according to customers' screening needs. Broken tea leaves are generally used for tea triangle bags. No matter which form of tea leaves, the purpose of screening is generally for grading.

Broken tea leaves are generally sieved with meshes of 20/30/40/50/60 and so on.

Bar-shaped tea leaves are generally sieved with apertures of 10mm/8mm/6mm/4mm/2mm, etc.

The purpose of the Tea leaf sifter machine is to separate the tea leaves into grades of different sizes, and also to sieve out the fines in the tea leaves to meet the sieving needs of different tea leaves across the country.

| Screen inner diameter | Fresh tea leaves |

| 3 mm diameter | screening small buds |

| 4 mm diameter | Screen pure buds |

| 5 mm diameter | Screen the hollow buds |

| 6 mm diameter | Screening of wrapped leaf buds |

| 8 mm diameter | Screen a small bud and a leaf |

| 10 mm diameter | Screen a bud and a leaf |

| 12 mm diameter | Screen one big bud and one leaf or one small bud and two leaves |

Featured Video

Technical Parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

-

Quickly separate the impurities in the tea, grading tea of different size & shapes

-

Tea leaf sieve machine Customer case

Tea leaf sieve machine has a feeding port at the upper end of the machine, enters the screen for sieving, and sieves the tea powder from the feeding port ...

-

Types of tea leaf sieve machine

Tea leaf sieve machine is mainly used to separate the tea leaves that have been broken, to disperse the agglomerated tea leaves, ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.