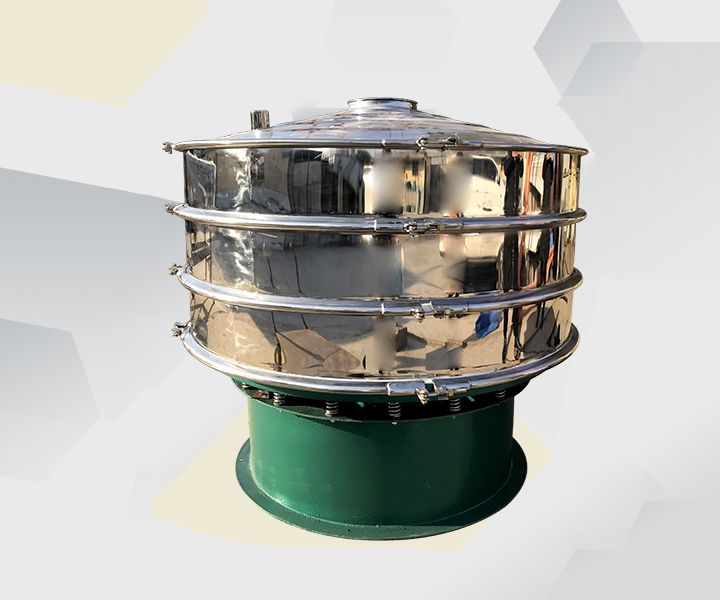

Vibrating Sifter

![[field:title/]](/uploads/211112/1-211112133151324.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

The minimum sieving is 500 mesh or 0.028mm, and the minimum filtering is 5 microns

1-5 layers, can carry out 2-6 levels of sorting or filtering at the same time

Impurities and coarse materials are automatically discharged, and continuous operation is possible.

Introduction of vibrating sifter

Vibrating sifter is a common type of fine screening equipment, suitable for sieving powders and particles, and can also be used to filter liquids. 0-500 mesh dry, wet, fine, coarse, large and small specific gravity powders and particles can be easily screened, within 5 microns The liquid material can be easily filtered.

Benefits of vibrating sifter

1. Wide screening range, can screen powder particles within 500 meshes, filter 5 micron slurry materials, each vibrating sifter can choose 1-5 layers of screens, which can carry out 2 to 6 levels of sorting and filtering at the same time.

2. It does not block the screen, and has a bouncing ball cleaning device. It can achieve the purpose of cleaning the screen by continuously hitting the screen. There is no blocking of the screen. All incoming materials are automatically discharged, and there is no storage in the machine, which improves the screening output and efficiency.

3. No dust pollution, fully sealed structure, no dust flying, no liquid leakage during the screening process.

4. Long service life and good maintenance: The rotating vibrating screen frame adopts the structure of the mother and the second screen to ensure the flatness and tension of the screen, preventing the material from impacting and collapsing the working net, and also preventing the bouncing ball on the screen from hitting the working net. , It only takes 3-5 minutes to change the screen, easy to operate and easy to clean.

Working principle of vibrating sifter

Vibrating sifter uses a vertical motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights, which can convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the screen Surface, the material on the screen surface expands and involutes outward movement. By adjusting the phase angle of the eccentric weight at the upper and lower ends of the motor, the movement trajectory of the material on the screen surface can be changed, so that the material can be finely screened. , Probability screening, etc.

Structure of vibrating sifter

Vibrating sifter is mainly composed of feed port, dust cover, discharge port, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, base and other parts.

Dust cover: prevent the material from spreading out, and also protect the external dust from entering, thereby contaminating the screening material.

Beam ring: used to fix the screen frame in the middle of the screen body.

Upper weight and lower weight: Changing the phase angle of the upper and lower weights of the vibration motor can change the movement trajectory and residence time of the material on the screen.

Spring: vibration damping and sound insulation.

Frame: Support the entire vibrating screen to keep its work stable.

Technical parameters of vibrating sifter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of vibrating sifter

Food industry: starch, powdered sugar, coffee powder, glutinous rice flour, soybeans, corn, peanuts, sesame, soy milk, vinegar, etc.

Pharmaceutical industry: Chinese medicine powder, medicine, vitamins, etc.

Chemical industry: paint, washing powder, paint, soda ash, lemon powder, resin powder, plastics, etc.

Abrasives, ceramics industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, special electrode powder, etc.

Papermaking industry: coating paint, clay slurry, black and white liquid, waste liquid, papermaking liquid, etc.

-

The round vibrating sifter is circular, and the material is fed from the center, moving in a spiral g ...

-

Used for screening, classifying and removing impurities in various powder ...

-

Any powder, granules and slurries can be screened efficiently....

-

How much is the food vibrating sifter

Food vibrating sifter mainly screen food materials, fine powder, micropowder, and some dry or wet mat ...

-

Vibrating screen for sieving iodized salt

Iodized salt is not uncommon in daily life. In the iodized salt processing technology...

-

What is the price of sesame vibro sifter?

Many users have asked? The price is so affordable, the quality of the equipment will not be greatly...

-

Circular sieve manufacturers

Because there are demand, there are many manufacturers of circular sieves on the market...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision and...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.