Round Vibrating Sifter

![[field:title/]](/uploads/211112/1-21111216240A43.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Sieving fine to 500 mesh or 0.028mm

Can be used with single-layer and multi-layer screens

Can control the time that the material stays on the mesh surface

What is a round vibrating sifter?

Round vibrating sifter is a vibrating screen that integrates classification, impurity removal and filtration. It is mainly made of carbon steel, stainless steel and all stainless steel. It has a single-layer or multi-layer design. The screen surface can reach 5 layers. Screen 6 kinds of materials with different particle size specifications.

During the screening process of the Round vibrating sifter, the material is distributed evenly on the screen (because the material is fed from the center, it will move in a spiral and gradual trajectory). The material can be determined on the screen by adjusting the tangential angle and rotation speed. The length of the residence time on the surface, so the accuracy of the material and the processing capacity are controllable with a circular vibrating screen.

What are the advantages of round vibrating sifter?

1. It is suitable for a wide range of materials, and can be sieved to 500 mesh or 0.028mm powder and granules, and liquid materials can be filtered to 5 microns.

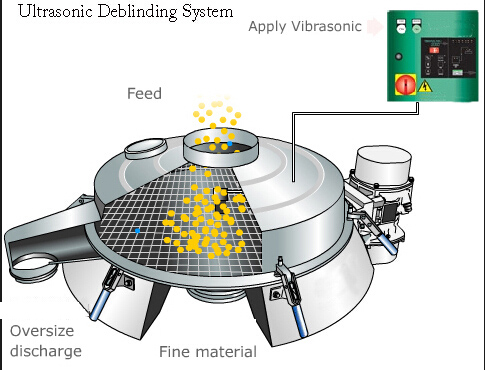

2. Equipped with a bouncing ball cleaning device, which can achieve the purpose of cleaning the screen by continuously hitting the screen without blocking the screen. For viscous and electrostatic materials, the ultrasonic cleaning device can be used.

3. Fully enclosed structure, no dust spillage, improve working environment.

4. It can sieve 1 to 5 layers of screens, and can carry out 2 to 6 levels of sorting or filtering at the same time.

5. Impurities and coarse materials are automatically discharged, and continuous operation is possible.

6. The discharge port can be rotated 360°, which is easy to operate.

How does the round vibrating sifter work?

Round vibrating sifter uses YZUL vertical vibration motor as the excitation source. The eccentric weight on the upper and lower ends of the vibration motor converts the rotational motion into horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; the material passes through The feed inlet enters the equipment. According to different material screening requirements, the material passes through 1-5 layers of sieving with different mesh metal woven screens. In this process, a cleaning device is located under the screens of each layer. (Bouncing ball) Continuously hitting the screen through frequency vibration, so that the materials on the screen can be smoothly screened through the screen, and effectively solve the problem of material blockage. After the materials of different meshes pass through the screens of the corresponding meshes of each layer It is discharged at the discharge port of each layer, and fina l ly achie ves the purpose of screening and removing impurities or filtering and grading.

Structure of round vibrating sifter

Round vibrating sifter is composed of inlet, dust cover, outlet, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, base and other parts.

Dust cover: to prevent the escape of dust.

Vibration motor: Vertical vibration motor is used, and the motor power can be selected from 0.18KW to 4.0KW. (The larger the diameter of the device, the greater the power of the motor used). For some special industries, explosion-proof vibration motors can be equipped.

Screen frame: Constrain the material to make the material produced within a certain range. Common materials are Q235 carbon steel and 304 stainless steel, and the thickness of the material is 2.0mm~3.0mm.

Beam ring: connect the bottom cone and the screen frame, the upper and lower screen frames, and also play a role in preventing material leakage.

Screen: The parts contacted by the material, the commonly used material is 304 stainless steel woven mesh.

Punching plate: Lift the screen to extend the service life of the screen. The commonly used material is 304 stainless steel.

Net cleaning device: It can be divided into three types of net cleaning devices: bouncing ball, ultrasonic, and rotating brush. Users can choose reasonably according to different production processes.

Bottom bucket: the part that supports the screen body and carries the vibration motor, the thickness is 3mm~6mm, and the thickness is also determined according to the diameter of the equipment.

Vibrating plate: It has the function of fixing the vibrating motor and connecting the screen body. The plate used is Q235 carbon steel with a thickness of 4mm~6mm.

Technical parameters of round vibrating sifter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of round vibrating sifter

Metallurgical industry: aluminum silver paste, mud, kaolin, quartz sand, alumina, artificial black aluminum, graphite, silicon carbide, sprayed soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.

Food industry: flour, milk powder, starch, fish meal, rice noodles, vitamins, condiments, dextrin, beverages, fruit juices, sugar, soy sauce, pineapple juice, yeast, etc.

Pharmaceutical industry: pharmaceutical intermediates, medical auxiliary materials, traditional Chinese medicine powder, traditional Chinese medicine liquid, western medicine powder, western medicine liquid, etc.

Chemical industry: paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder, etc.

Selection suggestions for Round Vibrating Sifter

1. Model selection guide

| Model parameters | Small (laboratory) | Medium (production line) | Large (industrial grade) |

| Screen diameter | 400-600mm | 800-1200mm | 1500-2000mm |

| Power | 0.25-0.75kW | 0.75-2.2kW | 3-7.5kW |

| Processing capacity | 0.1-2t/h | 2-10t/h | 10-30t/h |

| Applicable scenarios | R&D test, small batch production | Conventional production lines of food and chemical industry | Large batch screening of mining and metallurgy |

2. Material Selection Guide

The material of the circular vibrating screen affects the durability, adaptability and processing efficiency of the equipment. Choose the appropriate material according to the working environment and material type:

Stainless steel circular vibrating screen: suitable for food, medicine, chemical, petroleum, pharmaceutical and other industries, can resist corrosion, high temperature and easy to clean.

Carbon steel circular vibrating screen: suitable for conventional screening applications, suitable for dry, non-corrosive materials, low cost, but relatively poor durability and corrosion resistance.

Polyurethane circular vibrating screen: suitable for materials with high wear resistance requirements, such as sand, gravel, mineral powder, etc., which can extend the service life of the screen.

3. Layer Selection Guide

| Number of layers | Function | Typical applications |

| 1st layer | Simple impurity removal or coarse classification (2 types of particle size separation) | Grain stone removal, plastic particle removal of large impurities |

| 2nd layer | Preliminary classification (3 types of particle size separation) | Quartz sand classification (coarse sand/medium sand/fine sand) |

| 3rd layer | Fine classification (4 types of particle size separation) | Lithium battery materials (coarse powder/medium powder/fine powder/ultrafine powder) |

| 4-5th layer | Ultrafine classification or multi-stage recovery | Pharmaceutical powder preparation (simultaneous extraction of components with different mesh sizes) |

Circular vibrating screen manufacturer

Dahan Machinery is a company specializing in the research and development, production and sales of vibrating screening equipment, providing a variety of screening equipment including circular vibrating screens. Its circular vibrating screen is suitable for food, medicine, chemical, metallurgy, mining and other industries, with high screening accuracy, high screening efficiency and large processing capacity.

Customized design: supports special structures such as gate type, edge type and edge type, and adapts to different production line layouts.

After-sales guarantee: Provide screen life extension solutions (such as high-frequency vibration to reduce wear), on-site debugging and operation training.

Case reference: Serving mines and food companies in Henan, Shandong and other places, such as quartz sand grading, daylily impurity removal and other projects.

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Used to safely remove contaminants and lumps in powder.

-

Flour vibrating sieve is specially designed for product safety in flour mills, bakeries and other food processing plants.

-

Screening and filtering of particles, powders, liquids and other materials.

-

Satisfy various powder and particle screening requirements and liquid filtration requirements.

-

Potato Starch Vibrating Screen

The discharging port can be adjusted 360 degrees arbitrarily, which is convenient to connect with the scene.

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Granules, powders, and paddle materials can be used.

-

Standard test sieves are precision mesh screens used to separate particles based on size in various industries.

-

In the case that the mealworms are not harmed, the dry bugs are separated from the impurities, instead of manual sorting.

-

Ensure accurate particle size of metal powder and remove excessive contaminants.

-

Sesame sieve is also called sesame sieve machine or sesame sieving machine. Sesame sieving generally refers to sieve out the sand in the sesame or the carbon residue in the fried sesame.

-

Swing Vibrating Screen is a high-efficiency screening machine specially designed to meet the needs of large-scale and high-precision screening.

-

Different types of powder sieve machine

The powder sieve machine can be used for the screening of various powder materials...

-

Powder Sieving Machine for epoxy

Resin refers to a general term for a class of polymers containing two or more epoxy groups in...

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

Double layer rotary vibrating screen

Double layer rotary vibrating screen is a multifunctional and efficient screening equipment used for particle...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for...

-

Stainless steel straight screen

Stainless steel straight screen is an efficient and durable screening equipment, mainly used for rapid screening...

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy...

-

Vibrating Sieve for Powder

Vibrating sieve for powder is a special term for the screening of powder materials in various industries. In order...

-

Stainless steel straight-discharge screen

Stainless steel straight-discharge screen is an efficient and fast screening device, specially used for screening...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.