What are the functions of Corrosion resistant vibro sifter

Corrosion resistant vibro sifter is made of PP plastic (polypropylene plastic) for all parts in contact with the material, the beam ring and the bottom barrel are sprayed, the vertical vibration motor is installed, and the plastic vibrating screen effectively solves the oxidation and corrosion The steel material screening, impurity removal, and filtering plan ensure that the material will not deteriorate during the screening process.

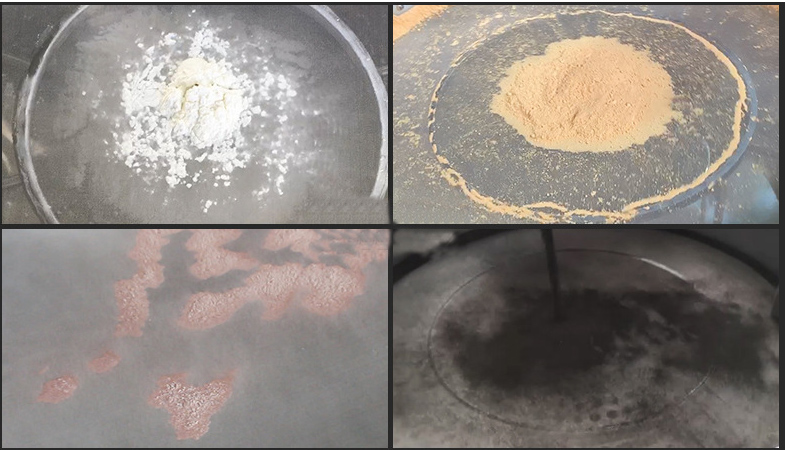

Corrosion resistant vibro sifter is also called plastic vibrating screen, plastic vibrating screen, plastic circular vibrating screen, plastic chemical filter vibrating screen, etc. in the national scope of use, but the main purpose of use is to make it more corrosive The materials are sieved and filtered. The plastic vibrating screen designed and developed by our company is specifically aimed at solving the problems that some special materials are prone to oxidation and corrosion after they come into contact with Q235 ordinary carbon steel and SUS304 stainless steel. The part of the plastic vibrating screen in contact with the material is made of PP plastic material, which is an effective solution to the screening, impurity removal and filtration of materials with oxidized and corrosive steel materials, and ensures that the materials will not deteriorate during the screening process. Plastic anticorrosive vibrating screen is currently an effective solution for screening, removing impurities and filtering materials with the characteristics of oxidation and corrosion of steel materials.

Corrosion resistant vibro sifter uses a vertical explosion-proof vibration motor as the excitation source. The eccentric weight on the upper and lower ends of the vibration motor converts the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, and transmits it to the sieve of the rotary vibrating screen. Surface; Dextrin enters the equipment through the inlet. According to different dextrin screening requirements, the dextrin passes through 1-5 layers of sieving with different mesh metal woven screens. In this process, it is located in each layer The net cleaning device (bouncing ball) under the sieve mesh continuously hits the stainless steel sieve through frequency vibration, so that the dextrin layer on the sieve can be screened smoothly, and effectively solves the problem of dextrin blockage. The dextrin passes through the screens of the corresponding meshes of each layer and is discharged from the discharge port of each layer, finally achieving the purpose of screening and removing impurities or filtering and grading. Adjusting the phase angle of the upper and lower ends can change the trajectory of dextrin on the screen surface.

-

Corrosion Resistant Vibro Sifter

The screen machine is made of polypropylene propylene pp material. ...

-

Plastic Powder Vibratory Sifter

Gentle screening will not damage any PVC resin structure, and it is not easy to generate static electricity. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.