vibro sifter machine

![[field:title/]](/uploads/211117/1-21111G5044X47.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

as long as the material is within 600 mesh. Easy screening.

which greatly improves the screening output and screening efficiency of the screen.

In response to the special needs of different industries

Introduction of vibro sifter machine

Vibro sifter machine is a high-precision sifter machine. The overall function is to separate dry materials into different particle size groups or separate solids from liquids. This machine has low noise, good sealing, high efficiency, low energy consumption, Simple operation and other characteristics; in addition, the equipment operator can set the speed of the material passing through the screen and the direction of the online movement, providing the maximum processing capacity and screening efficiency for any screening product, whether it is wet or dry material, heavy quality Or light, coarse or fine grain.

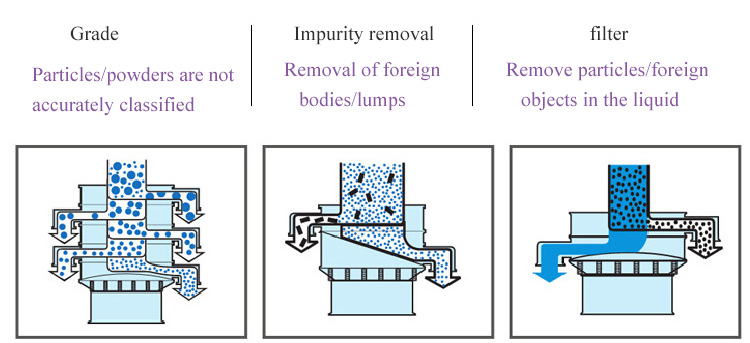

Function of vibro sifter machine

1. Classification: The vibro sifter machine can be used to continuously and accurately separate and screen the products, and the multi-layer use can separate and screen out six groups of products with different particle sizes at a time without inconsistent particle size ratio.

2. Liquid removal: It can be used in single layer or multi-layer, it can treat the mixture of solid and liquid very effectively, realize solid-liquid separation quickly, and filter out different target materials.

3. Removal of impurities: This equipment can quickly separate a large amount of materials and remove small parts of materials of different sizes.

Screening simulation diagram of three-dimensional rotary vibrating screen

Benefits of vibro sifter machine

1. In terms of mechanical power, the medium flange motor is adopted, and the three-dimensional power of horizontal, vertical and inclined power is more prominent, and the noise is low at the same time as the large power.

2. A wide range of materials, regardless of whether the material is dry or wet, fine or rough, heavy or light, as long as the material is in the range of 0-400 mesh, it can be sieved, even if the material is liquid or slurry, as long as the material is within 600 mesh. Easy screening.

3. Equipped with a professional screen cleaning device, the screen will not be blocked in the process of screening materials, which greatly improves the screening output and screening efficiency of the screen.

4. In response to the special needs of different industries, the three-dimensional vibrating screen has a unique design, such as the edge-added type, gate type, powerful type, sealed type and other different types.

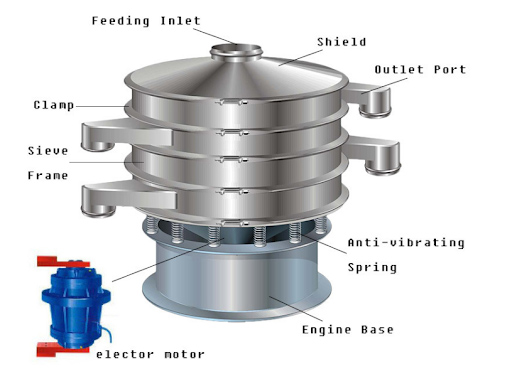

Working principle of vibro sifter machine

The vibro sifter machine uses the YZUL vertical vibration motor as the excitation source. The eccentric weight at the upper and lower ends of the vibration motor converts the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; the material passes through The material inlet enters the equipment. According to different material screening requirements, the material passes through the screen layer of the screen. In this process, the net cleaning device under the screen-the bouncing ball constantly hits the screen, so that the material on the layer of the screen can be Smooth through screen screening, and effectively solve the problem of material blocking the screen, the screened material and the screened material are discharged from different outlets, so as to achieve the purpose of screening and removing impurities or filtering and grading.

Structure of vibro sifter machine

Vibro sifter machine is composed of feed port, dust cover, discharge port, beam ring, screen, counterweight, upper weight, vibrating body, vibration motor, spring, lower weight, machine base and other parts.

Technical parameters of vibro sifter machine

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Application of vibro sifter machine

Vibro sifter machine can be used to remove impurities, classify and filter powder, granule and slurry materials in various industries.

Food industry: starch, milk powder, monosodium glutamate, soy milk, fruit juice, soy sauce, vinegar, etc.

Chemical industry: rubber powder, resin powder, paint, washing powder, paint, soda ash, lemon powder, rubber, plastics, etc.

Pharmaceutical industry: Chinese medicine powder, pharmacy, Chinese and Western medicine granules, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, welding rod powder, etc.

Abrasives, ceramics industry: alumina, quartz sand, mud, sprayed soil particles, etc.

-

Used for screening, classifying and removing impurities in various powder ...

-

Granules, powders, and paddle materials can be used ...

-

Made of 304 stainless steel, the inside and outside of the screen is polished ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision ...

-

What is the price of sesame vibro sifter?

The price of sesame vibro sifter of Xinxiang Dahan Factory is around $638~$1700 ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.