Airflow sieve for Chinese medicine powder

Airflow sieve for Chinese medicine powder plays a vital role in the Chinese medicine pharmaceutical industry and can be used specifically for screening Chinese medicine powder as an efficient powder screening equipment. It uses the principle of combining airflow and vibration to finely screen Chinese medicine powder, so that Chinese medicine powder can be graded according to particle size, thereby obtaining products that meet quality requirements and ensure the stability of Chinese medicine products.

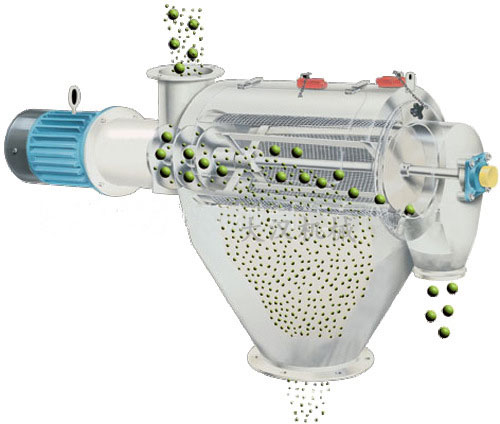

Working principle of Airflow sieve for Chinese medicine powder

The working principle of Airflow sieve for Chinese medicine powder is mainly based on the principle of airflow classification. Chinese medicine powder is fed into the screening chamber and meets high-speed airflow. Due to the different movement trajectories of powders of different particle sizes in the airflow, the coarser particles are more affected by gravity, move downward in a straight line, and are discharged through the screen; while the finer particles swirl with the airflow and are eventually carried away by the airflow to achieve the purpose of separation.

Advantages of Airflow sieve for Chinese medicine powder

1. Prevent agglomeration and blockage: Due to the action of airflow, Chinese medicine powder is in a suspended and dispersed state on the screen, which can effectively prevent agglomeration between powders. The airflow can also blow away the powder that blocks the sieve holes to prevent the screen from being blocked.

2.High efficiency and energy saving: The working mode of Airflow sieve for Chinese medicine powder, which combines vibration and airflow, can quickly move the Chinese medicine powder on the screen to achieve efficient screening. It consumes less energy during operation and has a high energy efficiency ratio.

3. High screening accuracy: Airflow sieve for Chinese medicine powder can accurately separate the different particle size components in the Chinese medicine powder to ensure that the particle size distribution of the Chinese medicine powder meets the requirements of Chinese medicine preparations. By selecting the appropriate mesh number of the screen, impurities and large particles that do not meet the requirements in the Chinese medicine powder can be effectively removed.

4. Easy to clean and maintain: The structure is relatively simple. After changing the Chinese medicine variety or completing the screening task, the screen can be easily disassembled for cleaning to avoid cross contamination between different Chinese medicine powders.

Application of Airflow sieve for Chinese medicine powder

Chinese medicine screening: Chinese medicine usually has impurities and unnecessary particles. Through the screening effect of Chinese medicine powder airflow screen, these impurities and particles can be separated to ensure the quality of Chinese medicine.

Manufacturing of Chinese medicine powder: Chinese medicine powder needs to accurately control the particle size during the manufacturing process. The Chinese medicine powder airflow screen can screen the Chinese medicine powder in detail to ensure the uniformity and quality of the product.

Manufacturing of Chinese medicine granules: Chinese medicine granules are made into solid particles by Chinese medicine powder. The Chinese medicine powder airflow screen can screen the powder and make the powder that meets the requirements into granules to improve the solubility and absorbability of the product.

Precautions for the use and maintenance of Airflow sieve for Chinese medicine powder

1. Screen installation: The screen should be installed correctly and cylindrical, and the upper and lower ends are fixed by steel wire ropes respectively, and the joints are overlapped and bonded with adhesives. When fixing the steel wire ropes at both ends, the screen needs to be adjusted to make it evenly tensioned.

2. Start-up and shutdown sequence: When starting, the induced draft fan should be turned on first, then the Chinese medicine powder airflow screen, and finally the discharge auger. The opposite is true when the machine is shut down.

3. Bag filter maintenance: The dust collecting bags of the bag filter should be shaken in time to prevent blockage.

4. Daily cleaning and maintenance: The operator should use the equipment correctly and do daily maintenance work such as cleaning, lubrication, tightening and corrosion prevention of the equipment. The electrical control box should be kept clean to prevent dust from falling in.

In summary, the Chinese medicine powder airflow screen has been widely used in the Chinese medicine industry due to its advantages of high efficiency, energy saving and high screening accuracy. With the continuous advancement of technology and the continuous development of the Chinese medicine industry, the Chinese medicine powder airflow screen will play a more important role.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Vegetable vibrating screen for draining water

Vegetable vibrating screen for draining water for draining water is a kind of equipment used in the food...

-

Bread Flour Vibrating Screen

Bread flour vibrating screen is a special equipment for screening bread flour. In the production process...

-

Paint vibrating screen

Corn starch vibrating screen is a specialized piece of equipment used for screening corn starch. It uses...

-

Popcorn vibrating screen

Popcorn vibrating screen is a screening equipment specially designed for the popcorn processing industry. It...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.