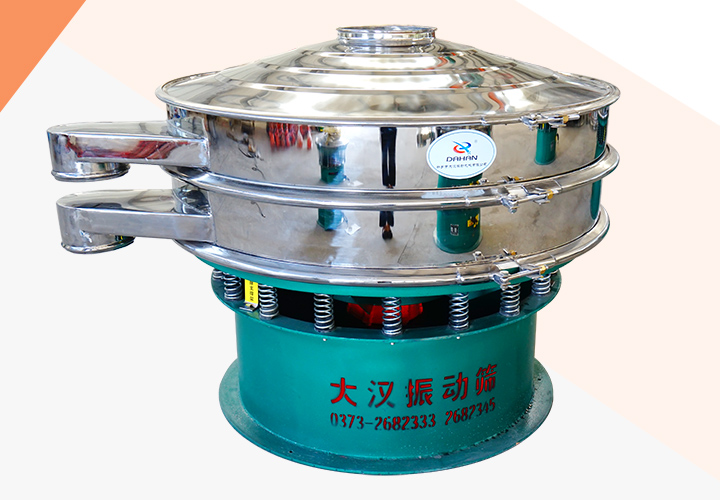

Almonds Sieve

Callback

| Mesh size: | 500 mesh or 0.028mm |

| Capacity: | 100-3300kg/h |

Size almonds without damaging the shell

Automatic discharge, realize mechanization, fast speed

SS304 stainless steel material, clean and hygienic, no pollution

Introduction of almonds sieve

Almonds sieve is used to separate the shelled almonds and almond shells, and remove the scattered almond residue in the almonds. Increasing the number of sieve layers can also be used for almond kernel grading. The vibrating sieve can be set up to 2-5 layers according to different purposes. Specifications of mesh to achieve different screening purposes. Single feeding, automatic separation of shells and kernels, simple operation, high production capacity, a single machine can meet the needs of the entire almond production line for shells and kernels separation, small footprint, and convenient production line.

Application of almonds sieve

Almonds sieve can screen almonds, various nuts, and dried fruit materials by size, grade, impurity removal, and soil removal. This equipment can divide almonds into multiple grades, up to five grades, and can also filter out impurities mixed in nuts. Sieve out, making nut sorting more accurate and cleaner.

Featured videos

Benefits of almonds sieve

1. It is used to remove oversized particles, impurities and other foreign matter. The multi-layer system can divide the product into 2, 3, 4, 5 different grades to improve the quality of the finished product before packaging.

2. The sieving can reach 0.028mm, and the finished product particles are uniform.

3. The parts in contact with materials are made of stainless steel 304, which is clean and hygienic and meets food requirements.

4. Equipped with an automatic cleaning device (bouncing ball device), which can effectively eliminate mesh blockage and improve screening efficiency.

5. With the automatic feeding system, continuous production can be realized, and impurities and coarse materials can be automatically discharged.

Difference between almond sieve and manual sieving

1. There are risks of contamination, cross-contamination, confusion and errors in the production process of manual manual sieving. The product quality cannot be guaranteed, and it is difficult to pass the sanitation standard. 0.2 RA All rubber parts are made of silicone specially used for the food industry, ensuring no material deposits and zero possibility of material contamination.

2. It is difficult to improve the screening efficiency by manual screening of pellets, and the waste of throwing during the screening process is serious, which is usually difficult to meet the production needs of enterprises. The almonds sievede1 closed system eliminates the problem of dust in the air. Manual interaction is pollution-free.

3. Due to the huge workload of manual screening of pellets, the labor cost is too high, and the long-term fatigue operation of workers will further affect the work efficiency. Almonds sieve can automatically process the screened impurities and coarse materials, saving labor and screening. You can then proceed to the next round of screening by yourself.

If you are aware of these problems and have been searching for solutions, congratulations, you have finally found the answer with us!

| ComparE items | Almond Sieve | Manual Sieving |

| Capacity | The single output of almond sieve is 3300 kg/h | Manual sieving 100 kg/hour per person |

| Performance | It can work continuously for 24 hours to ensure that there will be no pollution, hair and other sundries mixed with raw materials | Manual sieving does not meet the GMP standard, and there is no labor protection. Continuous sieving for more than 1 hour will easily cause overwork of workers, production problems and even accidents. |

| Cost | The machine is unmanned and can be used for a long time | Manual screening requires labor and high cost |

| Accuracy Efficiency | Use almond sieve to sieve almonds with more uniform particle size and high precision. | The accuracy of manual screening is not up to standard and unstable |

Technical parameters of almonds sieve

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

-

Suitable for screening and filtering of granules, powder, mucus and other materials ...

-

Stainless Steel Vibrating Sieve

The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high ...

-

The sieving fineness reaches 500 meshes (28μm) ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.