Bentonite for Powder Sieving Machine

Bentonite is an important industrial raw material with excellent adsorption performance, viscosity and stability. It is widely used in building materials, ceramics, coatings, cosmetics and other fields. The Powder sieving machine plays a vital role in the screening process of bentonite production. In the production process of bentonite, it can control the particle size and remove impurities of bentonite, thereby improving the quality and application performance of the product.

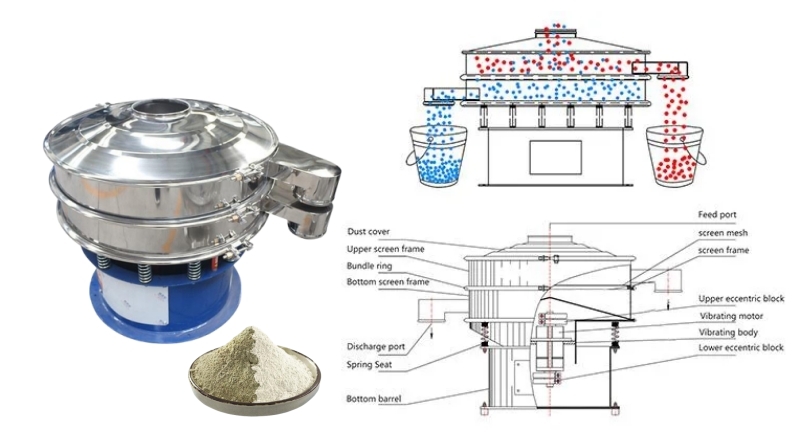

In the process of using a powder sieving machine to sieve bentonite, you first need to feed the bentonite powder into the feed port of the sieving machine. Usually, equipment such as conveyor belts or screw conveyors are used to continuously and evenly feed the bentonite powder into the powder screening machine. During the feeding process, the speed and uniformity of the feeding need to be controlled to ensure the stability of the screening process and the accuracy of the screening effect.

When the bentonite powder enters the sieving machine, the powder sieving machine starts to vibrate. Under the action of vibration force, bentonite powder is transported and screened on the screen. The powder sieving machine is equipped with screens of different apertures. According to the particle size requirements of the product and market demand, the appropriate screen is selected for screening. The aperture size of the screen determines the particle size range of the screening. By adjusting the aperture of the screen, precise control of the bentonite particle size can be achieved.

During the screening process, bentonite powder is subjected to vibration force, and particles of different sizes will pass through the screen according to their size. Larger particles are trapped above the screen, while smaller particles fall through the screen into the collecting trough below. Through the movement of powder sieving machine, bentonite powder is divided into particles of different particle sizes, achieving particle size control of bentonite. In addition, the powder sieving machine is equipped with an automated control system to realize automated operation and monitoring, improving the stability and consistency of production.

In short, powder sieving machine plays a key role in the sieving process in bentonite production process. Through the vibration of the powder sieving machine and the action of the screen, the particle size control of bentonite powder and the improvement of product quality can be achieved. The screening process requires attention to the maintenance and cleaning of the screen to ensure smooth screening. Through the application of powder sieving machine, the sieving process can be reasonably controlled and adjusted to meet the needs of different application fields, making the bentonite sieving process efficient, accurate and reliable, and improving the quality and performance of bentonite products.

-

Removes all oversized contamination or agglomerates from powder ...

-

metal powder sieving machine solution use

Achieving accurate particle size distribution is critical in all areas of metal powder production ...

-

metal powder sieving machine price

After choosing the model of the metal powder sieving machine for the customer, its price becom ...

-

Diatomaceous Earth for Powder Sieving Machine

The application of Powder Sieving Machine in the field of Titanium Dioxide has the advantages of efficient screening. ...

-

Diatomaceous Earth for Powder Sieving Machine

The application of Powder Sieving Machine in the field of Diatomaceous Earth has the advantages of efficient screening...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.